3004 Aluminum Strip

Alloy model: 3004 aluminum strip

Temper: O~H112, etc

Thickness: 0.1 mm-6.5 mm

Width: 3mm-2600mm

MOQ: 1 tons

Delivery: Ready stock: 7-10 days, future goods: 15-30 days

3004 Aluminum Strip Description:

3004 aluminum strip is an Al-Mn alloy. Its outstanding features are good corrosion resistance, high formability, good weldability, moderate strength, and cannot be strengthened by heat treatment. It is stronger than 3003 and is often used for extrusion and stretching. It is widely used in manufacturing food cans, packaging cans, cosmetic cans, etc.

Chemical Composition:

The manganese content of 3004 aluminum is higher than that of 3003, which gives 3004 better corrosion resistance. On the contrary, 3003 shows strong ductility and is suitable for deep drawing. 3004 is more suitable for wet or corrosive application environments and is suitable for contact with liquids.

|

Alloy |

Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each | Others: Total |

Al |

| 3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | – | 0.25 | – | 0.05 | 0.15 |

remainder |

Technical Parameters of 3004 Alloy Aluminum:

| Processing And Forming | 3004 aluminum strip can be processed through milling, drilling, cutting, cold bending, rolling, hot rolling, cold rolling and other processes. |

| Surface Treatment | Mill finish、coated、powder coated、anodized、polished mirror、embossed、etc. |

| Tolerances | As customer’s requirement |

| Loading Port | Qingdao Port,Tianjin Port,Shanghai port. |

| Price terms | FOB, CIF, CFR, CNF, etc. |

| Payment terms | L/C,D/A,D/P,T/T , West Union, Money Gram, Etc. |

| Standards | ASTM-B209,EN573-1,GB/T3880.1-2006 |

| Certificate | ISO, RoHS |

| Welding | Conventional argon arc welding, resistance spot welding, laser welding and other welding processes. |

| Heat Treatment | Solution treatment and aging treatment. |

| Forging | Hot forging, cold forging, etc. |

Mechanical Properties

|

Tensile Strength |

Yield Strength |

Elongation |

| 120MPa-150MPa | 40MPa-60MPa |

25%-30% |

Physical Properties

|

Grade |

3004 |

|

Density |

2.72 g/cm³ |

|

Melting Point |

660.3 °C |

| Elastic Modulus |

70GPa-80GPa |

| Conductivity |

39.4 MS/m |

| Thermal Expansion |

23.6 μm/m°C |

| Specific Heat Capacity |

0.896 J/g°C |

Advantages of 3004 Aluminium Strip:

- Corrosion resistance: 3004 aluminum can resist corrosion of liquid food and beverages, keeping them fresh and pure without affecting the quality of the product.

- Processability: 3004 alloy aluminum is easy to process and form, and is suitable for various forming processes such as deep drawing, bending, cutting, and cold rolling.

- Aesthetics: Aluminum 3004 has good surface treatment effects and can be applied to different aesthetic requirements through painting, sandblasting, anodizing and other processes.

- High temperature stability: 3004 is suitable for applications that operate in high temperature environments, such as kitchen appliances and cooking equipment.

What Is The Use of 3004 Aluminum Strip?

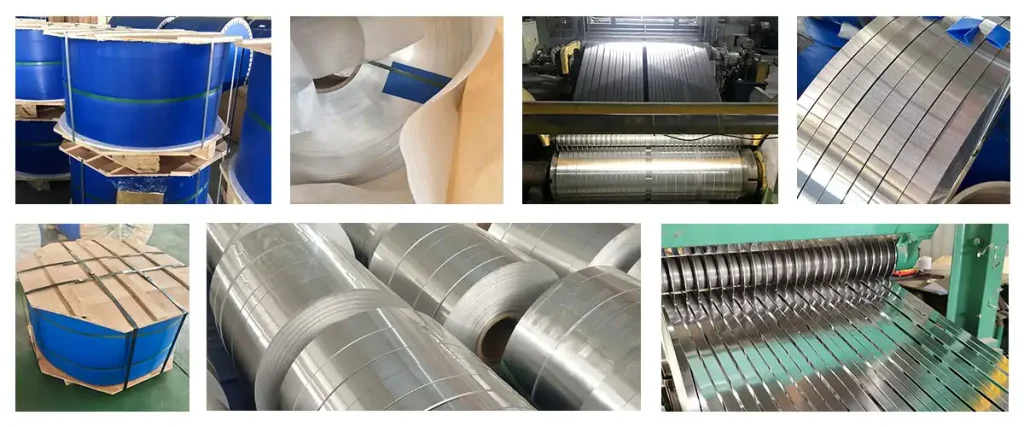

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

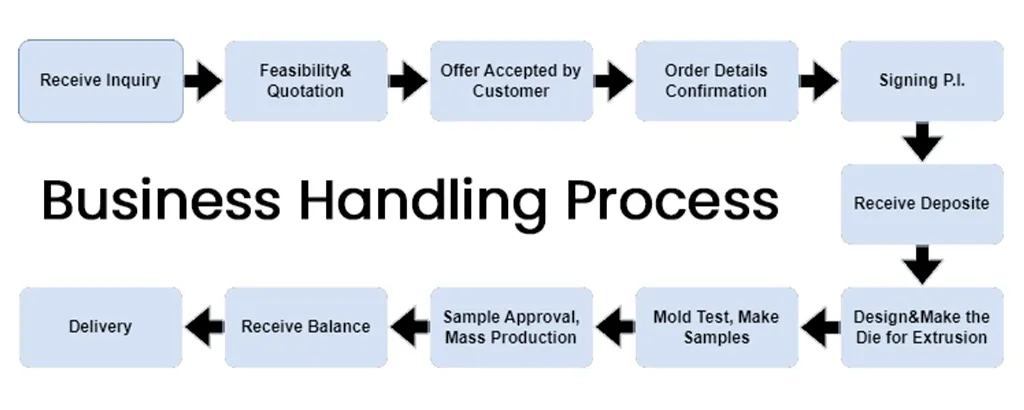

Business Handling Processes