Aluminum foil and aluminum sheet are two common forms of aluminum used in various industries and applications. While they are both made from aluminum, they serve different purposes due to their distinct characteristics and properties. Let’s explore the differences between aluminum foil and aluminum sheet:

Thickness

Aluminum foil: Aluminum foil is typically much thinner than aluminum sheet. It is commonly available in thicknesses ranging from 0.00017 inches (0.0043 mm) to 0.007 inches (0.18 mm). Due to its thinness, aluminum foil is often used for wrapping, packaging, cooking, and insulation purposes.

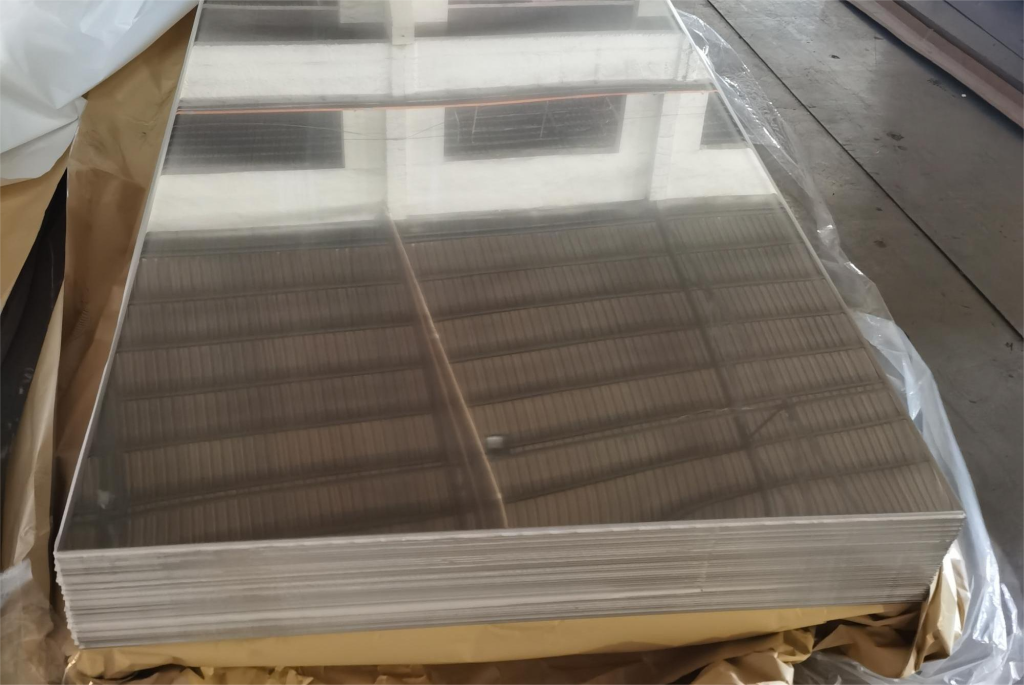

Aluminum sheet: Aluminum sheet, on the other hand, is thicker and comes in a variety of thicknesses, typically ranging from 0.008 inches (0.20 mm) to several inches. Aluminum sheet is commonly used in structural applications, construction, automotive parts, and aerospace components due to its strength and durability.

Surface Finish

Aluminum foil: Aluminum foil typically has a shiny, reflective surface on one side and a matte finish on the other side. This surface finish is achieved during the rolling process used to manufacture aluminum foil.

Aluminum sheet: Aluminum sheet may have various surface finishes, including mill finish, brushed finish, anodized finish, or painted finish, depending on the specific application requirements. These finishes can enhance the aesthetics and functionality of aluminum sheet products.

Usage

Aluminum foil: Aluminum foil is primarily used for packaging, wrapping food, cooking, insulating, and lining surfaces to reflect heat or light. It is also used in household items such as foil containers, trays, and disposable pans.

Aluminum sheet: Aluminum sheet is used in a wide range of applications, including roofing, siding, automotive body panels, aircraft fuselages, boat hulls, and industrial equipment. It is commonly fabricated into structural components, panels, plates, and extrusions for various construction and manufacturing purposes.

Formability

Aluminum foil: Aluminum foil is highly flexible and malleable, allowing it to conform to the shape of objects and wrap tightly around them. It can be easily folded, bent, or crumpled without breaking, making it suitable for packaging and cooking applications.

Aluminum sheet: Aluminum sheet is less flexible than aluminum foil but still retains good formability. It can be cut, bent, stamped, and welded to create custom shapes and structures for specific applications.

Conclusion

In summary, while both aluminum foil and aluminum sheet are made from aluminum, they serve different purposes and have distinct characteristics. Aluminum foil is thin, flexible, and primarily used for packaging and cooking, while aluminum sheet is thicker, stronger, and employed in structural, construction, and industrial applications. Understanding the differences between aluminum foil and aluminum sheet is crucial for selecting the appropriate material for a given application.