In many fields such as industrial platforms, logistics ramps, and architectural decoration, the balance between anti-skid performance, durability, and cost is often a problem. Traditional materials are either not anti-skid enough and pose safety hazards, or are too expensive to bear, or maintenance is cumbersome and increases long-term expenses.

Faced with these problems, 1060 aluminum tread plate has become an excellent material that cannot be ignored due to its excellent anti-skid performance, outstanding comprehensive performance, and significant economy.

Excellent anti-skid, building a solid foundation for safety

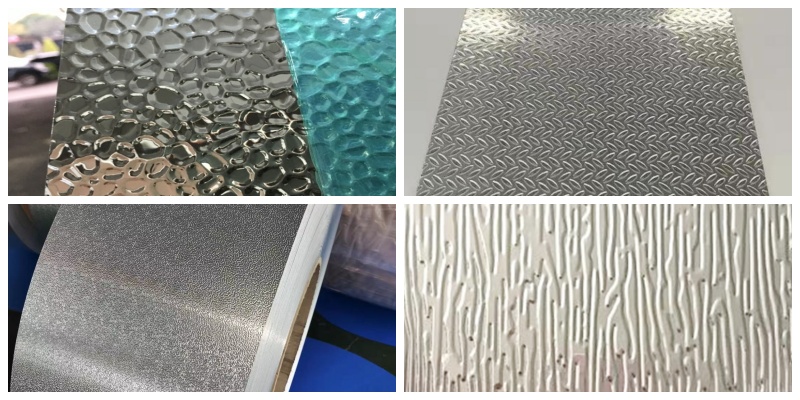

Safety is the top priority for industrial production and construction applications. The core value of 1060 aluminum tread plate is reflected in its unparalleled anti-skid performance. Through a precise rolling process, a stable raised pattern structure is formed on the surface of the plate. These tiny protrusions greatly increase the effective friction area between the sole or tire and the surface of the plate

- Diamond pattern: classic grid design, providing all-round anti-skid protection, especially suitable for crowded areas.

- Stripes (1/3/5 strips): directional guidance design, excellent longitudinal anti-skid, ideal for ramps and vehicle pedals.

- Orange peel pattern: fine and uniform convex points, both anti-slip and comfortable, suitable for indoor and outdoor stair treads and platforms.

Scientifically verified, its anti-slip coefficient R value can generally reach 0.5 – 0.7 (dry state), which is much higher than smooth aluminum plates, meeting or even exceeding the requirements of ASTM F1637 and other standards for anti-slip safety of walking surfaces. Especially in high humidity and oily environments, the pattern structure can effectively destroy the continuous liquid film and maintain reliable grip.

Table1: Main pattern types and recommended application scenarios of 1060 aluminum pattern plate

| Pattern type | Anti-slip characteristics | Typical application scenarios |

| Diamond pattern | All-round high anti-slip | Loading and unloading platform, dock operation area, factory workshop passage, pedestrian bridge |

| Stripe (3/5 stripes) | Excellent longitudinal anti-slip, good guidance | Loading and unloading ramps, truck/trailer bottom plate and pedals, production line conveyor belt side walkway |

| Stripe (1 stripe) | Basic longitudinal anti-slip, relatively flat surface | Light vehicle pedals, indoor stair pedals (medium anti-slip areas required) |

| Orange peel pattern | Uniform and delicate anti-slip, high comfort, easy to clean | Indoor and outdoor stair pedals, hospital/school corridors, kitchen operation area, viewing platform |

Core advantages of 1060 aluminum tread plate

The excellent performance of 1060 aluminum tread plate is rooted in the excellent characteristics of its parent material – 1060 pure aluminum. As a representative of industrial pure aluminum, 1060 has the following core advantages

- Excellent corrosion resistance: The dense aluminum oxide film naturally formed on the surface of aluminum gives it a strong ability to resist corrosion from the atmosphere, seawater and various chemical media. After the standard neutral salt spray test, 1060 aluminum plate can usually withstand hundreds of hours without serious corrosion, which is far better than ordinary steel, significantly reducing maintenance frequency and cost.

- Good conductivity: The conductivity of 1060 is as high as 58% IACS, which is better than most structural alloys. This makes it have unique application value in specific working areas where grounding is required or static dissipation is considered.

- Excellent processability: 1060 aluminum alloy has moderate strength, tensile strength of about 70-110 MPa, yield strength of about 30-50 MPa, elongation ≥15%, and excellent plasticity and forming ability. Whether it is cutting, bending, punching, or rolling, it can be easily achieved, greatly reducing the difficulty of processing and labor costs, and meeting the customization needs of complex engineering components.

- Excellent surface treatment adaptability: The substrate has high purity, providing an ideal base for subsequent surface treatments such as anodizing, spraying, and brushing, which can easily achieve diversified decorative effects and functional improvements.

Table2: Key performance comparison of 1060 aluminum tread plate vs. other commonly used metal plates

| Performance index | 1060 aluminum tread plate | Low carbon steel checkered plate | 304 stainless steel checkered plate |

| Density (g/cm³) | ≈2.71 | ≈7.85 | ≈7.93 |

| Anti-slip property | Excellent (R value 0.5-0.7) | Good | Good |

| Corrosion resistance | Excellent | Poor | Excellent |

| Conductivity | Excellent (≈58% IACS) | Poor | Poor |

| Easy processing | Excellent (good plasticity) | Medium | Poor (significant work hardening) |

| Initial material cost | Medium | Low | High |

| Life cycle cost | Low | Medium-high | High |

Cost advantage of 1060 aluminum tread plate

While ensuring key performance, 1060 aluminum tread plate shows strong competitiveness in cost control.

Significant material cost advantage

As a pure aluminum alloy, 1060 does not contain expensive alloy elements, and its raw material cost is much lower than rust-proof aluminum and hard aluminum, and is a fraction of the price of stainless steel. This greatly reduces the initial investment of the project.

Lightweight saves comprehensive costs

The density of aluminum is only about 1/3 of that of steel. Under the same area and thickness, the weight of aluminum tread plate is reduced by about 65%. This not only means lower transportation costs, but also significantly reduces the load requirements of the supporting structure, simplifies the foundation design and installation difficulty, especially in renovation projects or spaces with limited load-bearing capacity.

Maintenance-free/low-maintenance characteristics

Excellent corrosion resistance makes it unnecessary to perform regular painting and plating maintenance like steel in most environments. It saves long-term maintenance material costs, labor costs and downtime losses caused by maintenance, and the cost advantage of the entire life cycle is extremely prominent.

Easy installation

Good processability and light weight make on-site cutting, drilling, fixing and other operations more convenient and efficient, shortening the construction period and reducing the labor installation cost.

Wide Range of Applications

The unique combination of properties of 1060 aluminum patterned plates makes them suitable for a wide range of applications

Core Safety Applications

- Logistics and Material Handling: Truck and trailer floors and ramps, forklift loading platforms, warehouse temporary storage area floors. Slip-resistant and wear-resistant properties ensure safety for both people and vehicles, while lightweight design reduces vehicle weight.

- Industrial Facilities: Factory workshop walkways, equipment operation platforms, stair treads, and channel covers. Corrosion-resistant and easy to clean, suitable for oily environments.

- Ports and Terminals: Approach bridges, barge decks, and crane operation area floors. Resistant to marine climate corrosion.

- Public Transportation: Stair treads and connecting passage floors inside buses, subways, and train carriages. Reliable anti-slip properties and durable.

Architectural decoration applications

- Interior and exterior wall decoration: curtain walls, column cladding, and interior background walls. Through anodizing or spraying, rich colors and textures can be achieved, with a modern feel and lightweight safety.

- Commercial spaces: shopfronts, counter surfaces, and elevator cabin walls. Easy to clean and maintain, enhancing the quality of the space.

- Furniture and Cabinets: Especially suitable for modern minimalist-style cabinet panels and furniture surfaces. Moderate strength, easy to process and form.

- Public Facility Decoration: Such as walls and railing panels in port passenger terminals, reflecting industrial port characteristics while offering excellent weather resistance.

Sustainability of 1060 Aluminum Patterned Sheets

In today’s world where sustainability is increasingly important, 1060 aluminum patterned sheets are also an environmentally friendly choice

- Highly recyclable: Aluminum is one of the most recyclable materials on Earth, with recycled aluminum requiring only about 5% of the energy needed to produce virgin aluminum. At the end of its lifecycle, 1060 aluminum patterned sheets can be recycled and reused at nearly 100%, significantly reducing resource consumption and carbon emissions.

- Long service life: Its excellent corrosion resistance and physical stability ensure an exceptionally long service life, reducing the frequency of material replacement and waste generation.

- Lightweight and emissions reduction: When applied to transportation vehicles, its lightweight properties directly contribute to reduced fuel consumption and exhaust emissions.

1060 aluminum patterned plates seamlessly combine exceptional anti-slip safety, the superior corrosion resistance and conductivity of 1060 pure aluminum, excellent processing adaptability, and outstanding cost-effectiveness. Whether ensuring operational safety in harsh industrial environments or achieving a harmonious blend of aesthetics and functionality in architectural decoration, it demonstrates remarkable adaptability and irreplaceable value, delivering tangible cost savings for customers.

> The data in this article is based on typical H14-1060 aluminum plate and industry-standard testing criteria. Specific performance parameters may vary slightly depending on actual production processes, thickness, and surface treatment. Please refer to the latest product technical specifications for details.