In modern architecture and industrial design, aluminum sheeting has become a popular foundational material due to its lightweight, corrosion-resistant, easy-to-process, and recyclable properties. As designs move beyond a flat, smooth surface, unique textures and colors in aluminum sheeting have become a key requirement. Embossed and printed aluminum sheeting have emerged as a result. While both decorative aluminum materials, fundamental differences in their core processes give them distinct aesthetic and functional expressions. Understanding their differences is key to precise material selection.

Summary of Core Differences

Embossed aluminum plate

- utilizes giant rollers engraved with specific concave and convex patterns. During the rolling process or subsequent processing, hundreds or even thousands of tons of pressure are applied. Under this immense physical force, the aluminum sheet surface undergoes permanent plastic deformation, precisely replicating the roller’s texture.

- This creates a concave and convex pattern that corresponds to the roller’s pattern, such as orange peel, diamond lattice, brushed, and antique brick-like. The entire process is purely physical, with no additional color layers added.

Printed aluminum plate

- The printing process focuses on the aluminum sheet’s “skin.” This method uses advanced printing technology to impart a visual pattern onto a pre-prepared, flat aluminum substrate.

- Roller coating: Using an engraved coating roller, colored paint is precisely transferred to the aluminum surface, enabling complex color combinations through multiple layers of overprinting.

- Transfer printing: The design is first printed on a special carrier film, and then the ink is transferred to the aluminum coating through methods such as heat pressing. This is often used to create realistic wood and stone grains.

- Digital printing: Printing the design directly onto the aluminum coating offers the greatest degree of freedom, enabling photorealistic effects and customization.

- Regardless of the printing method, a transparent protective coating, such as highly weather-resistant PVDF fluorocarbon lacquer or PE polyester lacquer, is almost always applied after printing to protect the design and enhance durability.

Table1: Key Differences Summary

| Features | Embossed aluminum sheet | printed aluminum sheet |

| Essential Process | Physical deformation | Surface printing |

| Core Purpose | Enhanced performance + Decorative | aesthetics |

| Surface Condition | 3D relief; true 3D texture | Flat pattern |

| Tactile | Rough; relief | Smooth |

| Changed properties | Modified physical structure | No change to physical structure |

| Common effects | Orange pee; diamond; needle texture; Wood grain; stone; fabric; solid color | various patterns |

| Main Applications | Where structural/anti-slip requirements are strong | Where decorative requirements are high |

Appearance and Tactile Feel

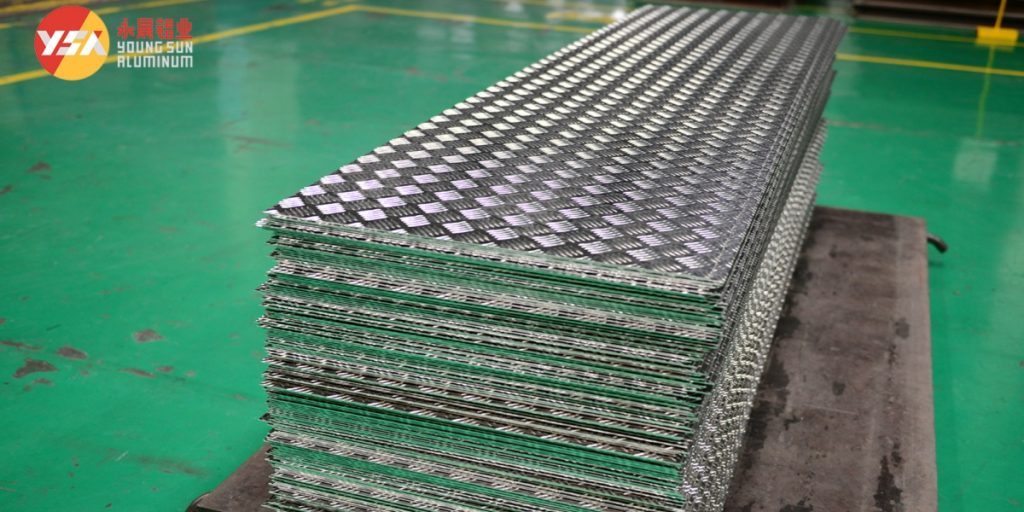

Embossed aluminum sheet

- Strong 3D effect: The surface has distinct relief, creating a three-dimensional pattern.

- Distinct tactile feel: The contours of the pattern can be clearly felt by touch.

- Relatively simple effects: The pattern is typically a repeating geometric pattern such as orange peel, diamond, checkered, barcode, or brick-and-stone. It primarily provides texture and quality, with minimal color variation. Variations are primarily due to light reflection off the 3D texture.

Printed Aluminum Sheet

- Rich Visual Patterns: Extremely complex and realistic patterns can be created, including various wood grains, marble patterns, fabric textures, artistic prints, photographs, and gradient colors. Visual expression is its core advantage.

- Smooth Surface: The printed layer and transparent protective coating create a typically smooth, flat surface. The smooth coating surface is felt, and the underlying aluminum sheet’s structural texture is invisible.

- Rich Colors: Virtually any color and complex color combinations can be achieved.

Features

Embossed Aluminum Sheets

- Wear and Scratch Resistance: The embossed texture hides minor scratches, and the pattern is integral to the metal, making it difficult to wear away.

- Excellent Slip Resistance: The three-dimensional texture increases surface friction, providing excellent anti-slip properties.

- Fingerprint/Smudge Resistance: The texture helps disperse light and hide fingerprints and stains.

- Structural Strength: The embossing process can sometimes slightly increase the rigidity of the aluminum sheet.

Printed Aluminum Sheets

- Highly Decorative: Vivid and diverse patterns and vibrant colors are available, meeting personalized decorative needs.

- Weather and Corrosion Resistance: This performance depends primarily on the quality of the surface coating. High-quality coatings offer excellent resistance to UV rays, acids and alkalis, stains, and weathering. High-quality PVDF fluorocarbon coatings can maintain color and gloss for up to 20 years or more.

- Easy Cleaning: Smooth surfaces are generally easier to wipe clean.

- Coating Durability: The surface pattern and color depend on the coating. Poor or damaged coatings can damage or fade the pattern.

Main Applications

Embossed patterned Aluminum Sheet

- Applications where functionality and durability are key: such as elevator cabins, subway/high-speed rail/bus interior panels, ship bulkheads, ceilings, curtain walls, industrial equipment casings, anti-slip walkways, cold storage panels, furniture, etc.

- Applications where anti-slip properties or scratch concealment are required.

Printed patterned Aluminum Sheet

- Applications where decorative effects and aesthetics are key: such as building interior and exterior wall decoration, suspended ceilings, interior partitions, furniture panels, home appliance panels, advertising signs, display racks, interior decorative elements, etc.

- Applications where specific patterns, wood grain, stone grain, or other simulated effects or artistic expression are required.

Key Decision Factors

What are the Core Needs?

- Primarily seeking wear resistance, anti-slip properties, scratch resistance, and scratch concealment—choose embossed aluminum sheet.

- Primarily seeking rich patterns, realistic imitation effects, and vibrant colors—choose printed aluminum sheet.

- Want the visual effect of a realistic texture, along with a truly three-dimensional feel and durability?— Choose embossed printed aluminum sheet.

Application Environment

- For applications with high traffic volume, prone to wear and scratches, and requiring anti-slip safety, such as public transportation and industrial flooring— choose embossed sheet or its composite material.

- For applications emphasizing aesthetics, creating a sense of atmosphere, and requiring a smooth feel, such as architectural curtain walls, interior wall coverings, furniture panels, and home appliances? —Choose printed aluminum sheet or composite material.

- For harsh outdoor environments, ensure the surface coating is weather-resistant.

Budget Considerations

Generally speaking, the cost of basic embossed and basic printed sheet is similar. However, the cost of highly realistic printed sheet, sheet with premium coatings, and embossed printed composite sheet increases significantly.

Embossed and printed aluminum sheet are like two masters of the decorative aluminum world: one specializes in “tactile sensation,” using the power of physics to carve a tangible, three-dimensional poem into the metal; the other focuses on “visual perception,” using color technology to create a truly illusory painting on the surface. They are not simple substitutes, but professional solutions for different design intentions and usage requirements.