What Is Holographic Film

Holographic film uses color holography, dynamic imaging, and other technologies to transfer holographic images to PET, BOPP, and PVC through molding and then uses lamination, hot stamping, and other methods to produce a laser effect on the film surface.

This article will introduce you to the characteristics, types, working principles, and shortcomings of holographic film and provide you with a complete holographic film navigation.

Holographic Film Features

- Good smell, strong anti-counterfeiting, beautiful, green, environmentally friendly

- Ink-resistant, water-vapor barrier, strong carbon dioxide capacity

- High gloss, anti-static, anti-adhesion, good printing

Holographic Film Material Types

BOPP laser film: high tensile strength, good barrier properties, high transparency. The thinnest is 1.8 filaments. Disadvantages: lower elongation than PP, poor heat sealing performance, difficult to seal when used independently, and generally compounded with PE and other films with good heat sealing properties when used.

PET laser film: polyester, its main features: good weather resistance, high temperature resistance of 100-150 degrees, good hardness and flatness. The thinnest is 1.2 filaments. Disadvantages: cannot be used on products with angles or corners.

PVC laser film: polyvinyl chloride; its characteristics are: good softness and good weather resistance (SPVC) Our factory only makes 4 filaments, generally used for self-adhesive products. Disadvantages: not environmentally friendly, so many international brands rarely use products of this material. This product is mainly used for anti-static protection and the surface of wooden speakers.

PE laser film: polyethylene, widely used in the protective film industry; its main features are low price, softness, good extensibility, environmental protection, and pollution-free; generally, such products have passed the EU ROHS environmental pollution test. Disadvantages: poor weather resistance; this material is not suitable for use at high temperatures, generally within 60 degrees.

How Does Holographic Film Work

The working principle of laser film is based on the principle of optical interference and reflection. The specific reasons are as follows:

When light hits the surface of the laser film, light waves of various wavelengths interfere. By precisely controlling the thickness and refractive index of each layer of material, certain wavelengths of light can be mutually enhanced, while other wavelengths of light are weakened or eliminated. This phenomenon forms color changes and the appearance of patterns.

During the manufacturing process of laser film, holographic technology is used to generate and transfer patterns. These patterns can be three-dimensional effects, dynamic rainbow effects, etc., which are realized by computer dot matrix lithography technology and holographic technology.

Holographic film is widely used in anti-counterfeiting labels, packaging materials, and decorations and can display different colors and effects at different angles and lighting conditions.

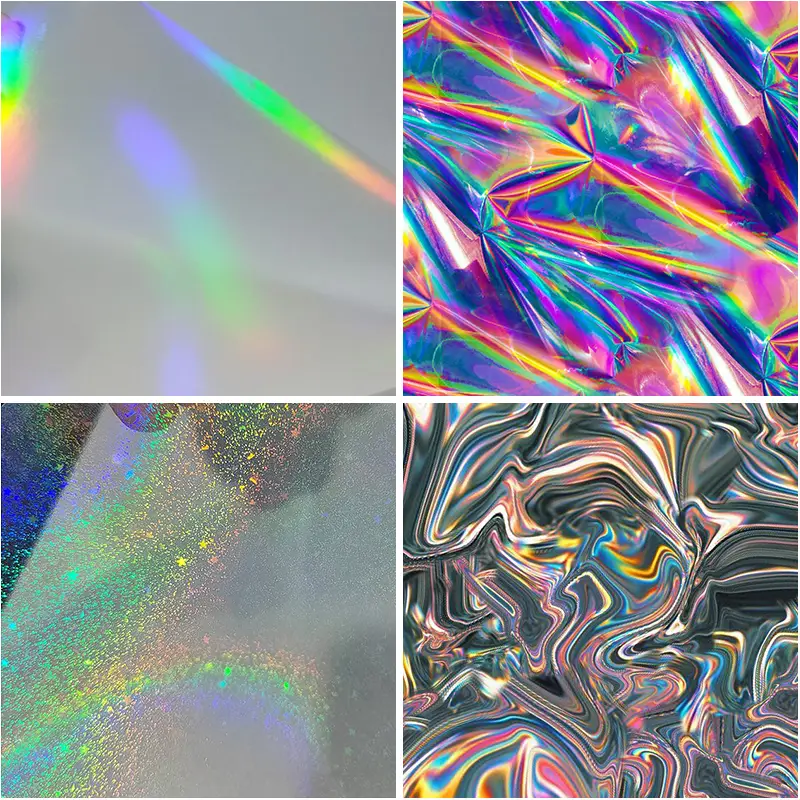

Holographic Film Pictures

Holographic Film Types And Applications

Holographic dielectric film:

Holographic dielectric film can be divided into BOPP dielectric film, PET dielectric film, etc. according to the material. Holographic dielectric film refers to a dielectric layer compounded on the basis of holographic transparent film, in which this dielectric layer can protect the pattern or text in the laser film. Its holographic brightness is several times stronger than that of ordinary transparent film, and the holographic pattern is acid and alkali resistant, cannot be wiped off, and effectively protects the layer.

Holographic washed aluminum film:

Holographic film washed aluminum is a product formed by the production process of aluminum-plated laser film after printing, aluminum washing, coating, etc. The washed aluminum film has higher technical content and more eye-catching visual effects, and the appearance is more exquisite. Laser-washed aluminum film applications: notebook covers, water-washed lace, cigarette pull lines, packaging boxes, handbags, cards, sealing tapes, daily chemicals, medicines, craft gifts and other mid-to-high-end products.

Holographic aluminized film:

Holographic aluminum-plated film is processed by vacuum aluminum plating; it has the characteristics of plump and smooth aluminum-plated layer, good adhesion of aluminum layer, strong adhesion to ink, and is suitable for various printing such as lithography, gravure, and flexographic printing; the laser film It is widely used in flexible packaging, handbags, wrapping paper, gift boxes, composites, decoration, laser holographic anti-counterfeiting, laser embossing, and other fields.

Holographic rainbow film:

The color of holographic rainbow film is formed by light interference, and the color varies with different observation angles. Holographic color film is divided into red, yellow, blue, green, purple and other colors. It can be composited with different colors of paper, plastic, and artificial leather. After composite, it can also be embossed, hot stamped, and printed to create patterns on the surface of the rainbow film, making it more colorful. The use of laser film is suitable for handbag packaging paper, gift boxes, and other fields.

Holographic transparent film:

Use: Mainly used for laminating paper products, transparent packaging bags for audio-visual products and clothing, etc. The holographic pattern has no dielectric layer protection. Features: good transparency, surface brightness, small number of crystal points, uniform thickness, accurate gram weight, and good anti-counterfeiting performance.

Holographic transfer film:

Features: The holographic laser film is applied to the cardboard with a transfer laminating machine, and the film is peeled off to become laser transfer paper. It does not contain any plastic components and the surface can be directly printed. Use:

(1) It can be composited with copper plate, white card, and white board paper for printing, and the laser effect is good.

(2) It is suitable for laminating high-end medicine boxes, wine boxes, gift boxes, books, magazines, paper boxes, and other paper products.

(3) It is suitable for laminating high-end counterfeit paper boxes.