In today’s world, materials play a crucial role in various industries, from manufacturing to construction and beyond. Among the many materials utilized, aluminum alloy and plastic stand out for their versatility and widespread use. But when it comes to strength, which material reigns supreme? This article delves into the comparison between aluminum alloy and plastic, exploring their respective strengths and applications.

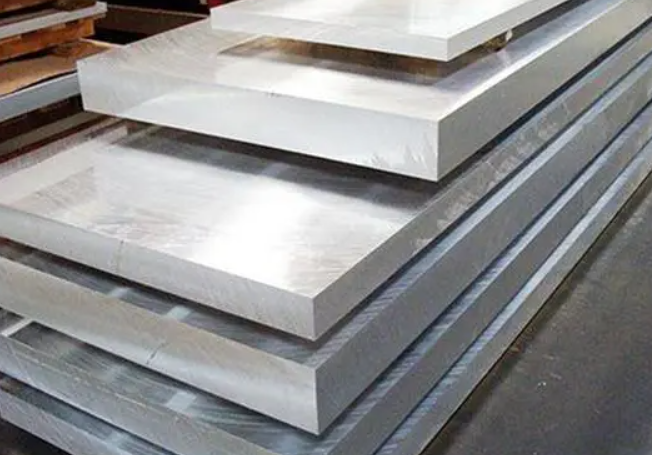

Understanding Aluminum alloy

aluminum alloy is a lightweight metal known for its excellent strength-to-weight ratio. It is widely used in industries ranging from aerospace to automotive due to its durability, corrosion resistance, and versatility. aluminum alloy alloys can be tailored to specific applications, making them suitable for a wide range of products, including aircraft frames, automotive components, and consumer electronics.

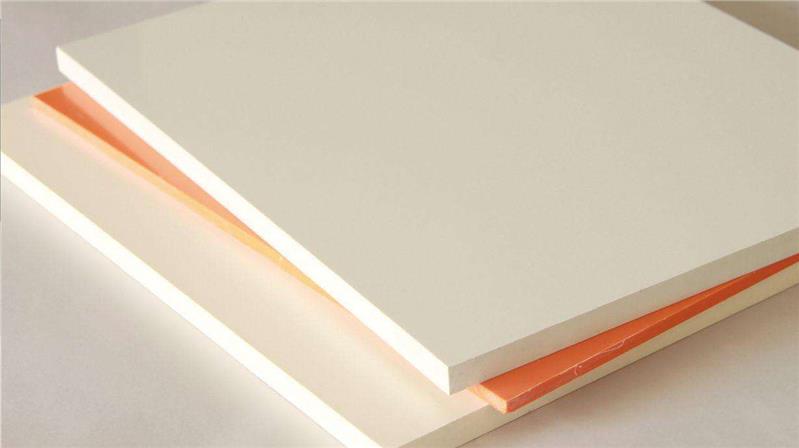

Examining Plastic

Plastic, on the other hand, is a synthetic polymer that can be molded into various shapes and forms. It offers advantages such as affordability, flexibility, and ease of manufacturing. Plastics come in different types, each with its own properties, including high strength-to-weight ratios, chemical resistance, and electrical insulation. Common types of plastic include polyethylene, polypropylene, polycarbonate, and acrylic.

Strength Comparison

When comparing strength, it’s essential to consider different aspects, including tensile strength, compression strength, and impact resistance. In general, aluminum alloys tend to have higher tensile strength and stiffness compared to most plastics. This makes aluminum alloy more suitable for applications requiring load-bearing capabilities, such as structural components in buildings and vehicles.

However, plastics excel in other areas. Certain types of plastics, particularly reinforced plastics like fiberglass-reinforced polymers (FRP) or carbon fiber-reinforced polymers (CFRP), can offer comparable or even superior strength-to-weight ratios compared to aluminum alloy. Additionally, plastics often outperform aluminum alloy in terms of corrosion resistance, thermal insulation, and electrical insulation.

Applications

Both aluminum alloy and plastic have their unique applications based on their strengths and properties. aluminum alloy is commonly used in industries requiring high strength, such as aerospace, automotive, and construction. It is also prevalent in consumer products like smartphones, laptops, and kitchenware. On the other hand, plastic finds extensive use in packaging, consumer goods, medical devices, and construction materials.

Conclusion

In the debate between aluminum alloy and plastic strength, the answer is not straightforward. While aluminum alloy generally offers higher mechanical strength, plastics boast versatility, affordability, and specific strength properties that make them indispensable in various applications. Ultimately, the choice between aluminum alloy and plastic depends on the specific requirements of the application, considering factors such as strength, weight, cost, and environmental considerations.