Introduction

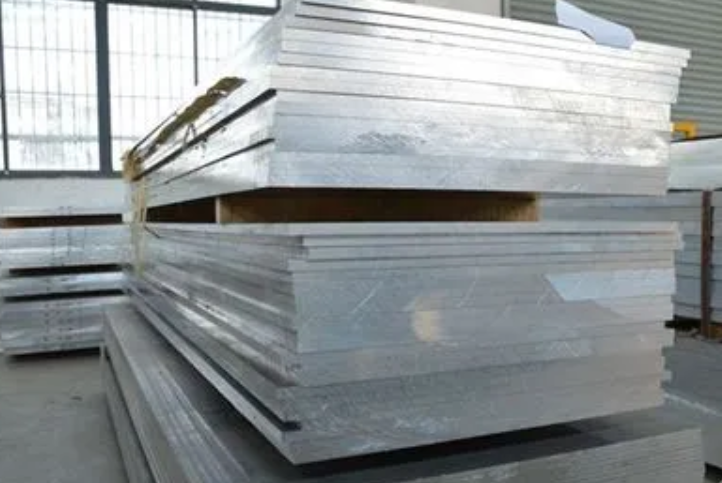

In the realm of aluminum alloys, the 5052-H32 alloy stands out for its exceptional combination of properties, making it a versatile and widely used material across various industries. From aerospace to marine engineering, automotive to architecture, the 5052-H32 alloy finds applications in diverse fields, owing to its remarkable strength, corrosion resistance, and formability.

Understanding the Composition

The 5052-H32 alloy belongs to the 5xxx series of aluminum alloys, which are primarily composed of aluminum, magnesium, and a few other trace elements. The “H32” designation indicates the tempering process applied to the alloy, with “H” representing strain-hardened and “32” signifying the specific degree of strain hardening.

Exceptional Strength and Durability

One of the key characteristics of the 5052-H32 alloy is its excellent strength-to-weight ratio. Despite its relatively low weight, this alloy offers impressive tensile and yield strengths, making it suitable for applications where strength and durability are paramount. Whether used in structural components or load-bearing elements, the 5052-H32 alloy provides reliable performance under challenging conditions.

Corrosion Resistance

Another notable feature of the 5052-H32 alloy is its exceptional corrosion resistance, particularly in marine environments. The addition of magnesium to the alloy enhances its resistance to saltwater corrosion, making it an ideal choice for marine applications such as boat hulls, ship components, and offshore structures. Additionally, the alloy’s resistance to atmospheric corrosion ensures longevity and reliability in outdoor settings.

Formability and Machinability

The 5052-H32 alloy offers excellent formability, allowing it to be easily shaped and fabricated into various components and structures. Whether through processes like bending, forming, or welding, this alloy retains its mechanical properties and integrity, enabling manufacturers to achieve intricate designs and complex geometries. Furthermore, its good machinability facilitates precision machining operations, enhancing productivity and efficiency in manufacturing processes.

Diverse Applications

Due to its superior properties and versatility, the 5052-H32 alloy finds widespread applications across numerous industries. In the aerospace sector, it is used for aircraft fuselage panels, wing skins, and structural components. In automotive manufacturing, it contributes to lightweight body panels, chassis components, and fuel tanks. Additionally, in architectural projects, it lends itself to building facades, roofing systems, and decorative elements. These are just a few examples of the diverse applications of the 5052-H32 alloy, highlighting its importance across various sectors.

Conclusion

In conclusion, the 5052-H32 aluminum alloy stands as a testament to the ingenuity and versatility of modern materials engineering. Its remarkable combination of strength, corrosion resistance, formability, and machinability makes it an indispensable material in numerous industries. As technological advancements continue to drive innovation, the 5052-H32 alloy remains at the forefront, enabling the creation of durable, efficient, and high-performance solutions for a wide range of applications.