Introduction

Aluminum mesh, known for its versatility and durability, has found widespread use in various industries and applications, from construction to filtration systems. One of its key attributes is its resistance to rust, a quality that sets it apart from traditional iron or steel mesh counterparts. In this article, we delve into the intricacies of aluminum mesh, exploring its rust-resistant properties and shedding light on its applications and maintenance practices.

Understanding Aluminum and Rust

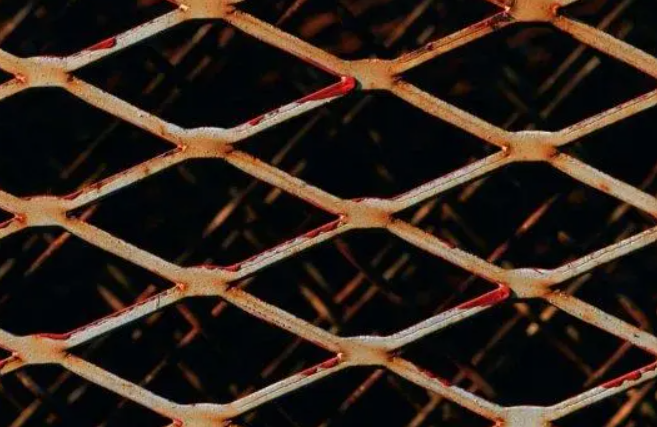

Unlike iron or steel, aluminum does not rust in the conventional sense. Rust is the result of the oxidation of iron-based metals, leading to the formation of a reddish-brown coating. Aluminum, on the other hand, undergoes corrosion, typically manifesting as a white, powdery substance known as aluminum oxide. This oxide layer acts as a protective barrier, guarding the underlying aluminum from further corrosion.

Factors Influencing Corrosion

While aluminum mesh boasts inherent corrosion resistance, several factors can influence its susceptibility to corrosion. Exposure to acidic or alkaline environments, high levels of humidity, and contact with certain chemicals or salts can accelerate corrosion. Additionally, mechanical damage or abrasion to the protective oxide layer can compromise the rust resistance of aluminum mesh.

Applications of Aluminum Mesh

The rust-resistant properties of aluminum mesh make it an ideal choice for a myriad of applications across diverse industries. In construction, it is widely used for architectural accents, sunscreens, and ventilation systems, where exposure to the elements necessitates corrosion resistance. In the automotive sector, aluminum mesh finds application in radiator grilles and air intake systems, where durability and rust resistance are paramount. Moreover, in industrial settings, aluminum mesh serves as an essential component in filtration systems, sieves, and shielding applications.

Maintenance and Care

While aluminum mesh exhibits excellent rust resistance, proper maintenance is essential to prolong its lifespan and performance. Routine cleaning to remove dirt, debris, and contaminants helps prevent the buildup of corrosive agents. Additionally, applying protective coatings or finishes can enhance the corrosion resistance of aluminum mesh, particularly in harsh environments. Regular inspections for signs of corrosion or damage allow for timely repairs or replacements, ensuring the continued effectiveness of aluminum mesh installations.

Conclusion

Aluminum mesh stands as a testament to the remarkable properties of this versatile metal. Its inherent rust resistance, coupled with its strength and lightweight nature, make it a preferred choice across a spectrum of applications. Understanding the factors influencing corrosion, along with implementing appropriate maintenance practices, ensures that aluminum mesh continues to deliver optimal performance and longevity in diverse settings. As industries evolve and technological advancements propel innovation, aluminum mesh remains a steadfast solution, bridging the gap between functionality and durability in the modern world.