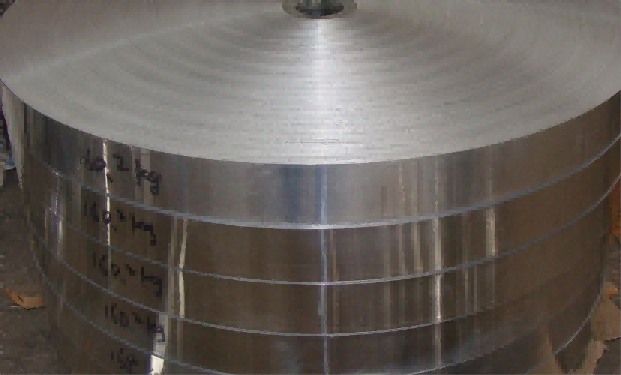

In the realm of aluminum alloys, 1060 aluminum strip stands out as a commonly used material with specific chemical compositions and performance characteristics. Below is a detailed exploration of 1060 aluminum strip.

Chemical Composition

1060 aluminum strip primarily consists of aluminum, with a purity reaching up to 99.6%, ensuring excellent electrical conductivity and thermal conductivity. While minor traces of other elements like silicon, iron, and magnesium may be present, their concentrations are typically negligible and do not significantly affect the primary properties.

Characteristics and Performance

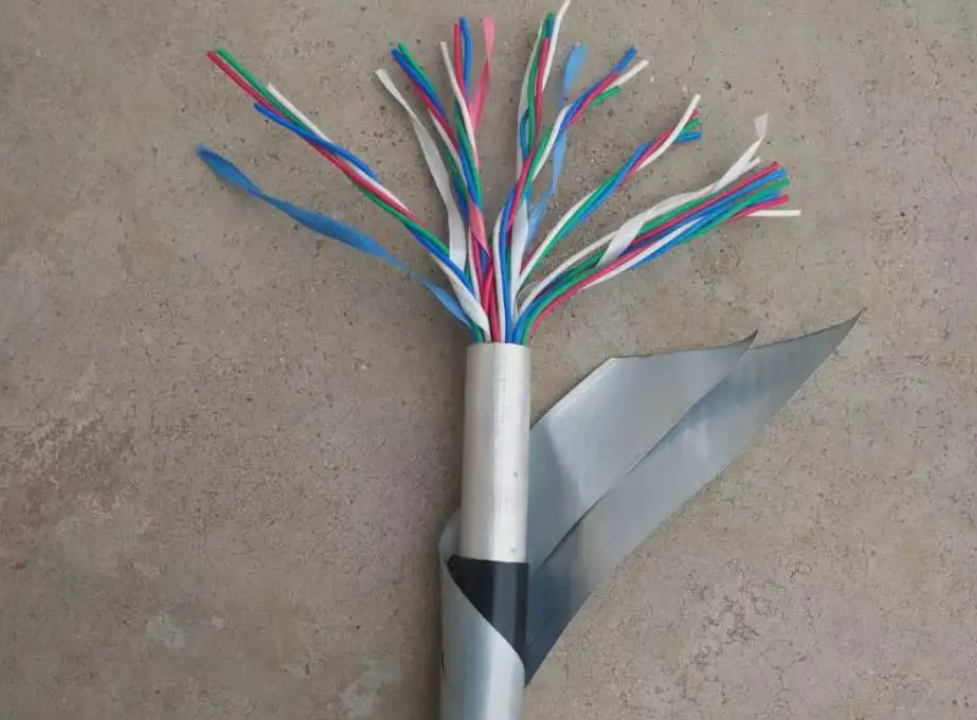

Excellent Electrical Conductivity The high purity of 1060 aluminum strip contributes to its exceptional electrical conductivity, making it widely used in electrical applications such as conductors for wires and cables.

Good Machinability Due to its high purity and relatively low hardness, 1060 aluminum strip is easy to process and shape through rolling, stretching, and other manufacturing processes, enabling the production of various shapes and sizes of products.

Superior Corrosion Resistance 1060 aluminum strip exhibits excellent corrosion resistance, making it suitable for applications in corrosive environments such as chemical industries and marine environments.

Good Weldability 1060 aluminum strip is easily weldable using conventional welding methods such as gas shielded welding and resistance welding, catering to various joining requirements.

Applications

1060 aluminum strip finds widespread applications across multiple industries, including but not limited to:

Electronics and Electrical Appliances Used in the manufacturing of wires, cables, transformers, and inductors due to its high electrical conductivity.

Architectural Decoration Suitable for indoor and outdoor decoration, ceiling panels, wall panels, and other decorative materials.

Chemical Industry Utilized in the fabrication of chemical equipment, storage tanks, pipelines, and other corrosion-resistant equipment.

Refrigeration Equipment Employed in the production of refrigerators, condensers, and other refrigeration equipment components.

Surface Treatment

Depending on specific application requirements, 1060 aluminum strip can undergo various surface treatments such as anodizing, painting, polishing, etc., to enhance its surface properties and aesthetics.

In conclusion, 1060 aluminum strip, characterized by its high purity and excellent properties such as electrical conductivity, machinability, corrosion resistance, and weldability, finds versatile applications across diverse industries. Its wide-ranging uses and reliable performance make it an indispensable material in both industrial and consumer sectors.