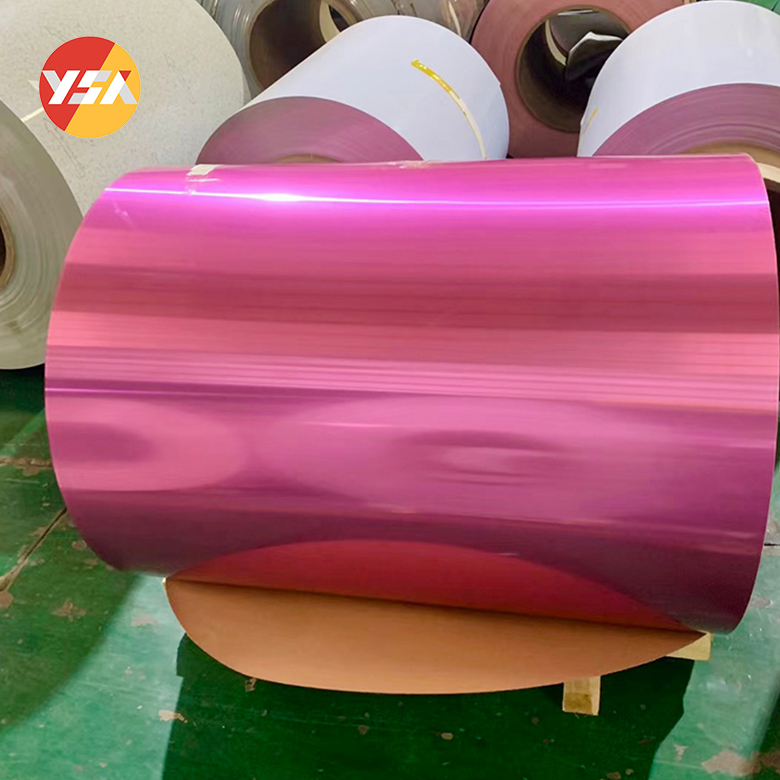

In the realm of modern architecture and decoration, the widespread use of color coated aluminum coil has become a trend. Its distinctive appearance, excellent durability, and ease of processing make it the preferred choice for architects and decorators. However, to unleash the full potential of color coated aluminum coil, not only is correct usage essential but also meticulous maintenance. Let’s delve into how to strike a balance between the utilization and upkeep of color coated aluminum coil to ensure its long-term beauty and functionality.

Protective Film

The protective film serves as the “first line of defense” for color coated aluminum coil. This thin layer not only shields the surface from scratches and contaminants but also provides additional protection post-installation until the project is completed. Therefore, handling and installing color coated aluminum coil require extra caution to avoid damaging this crucial protective layer.

Installation Environment

The proper installation environment is key to ensuring the long-term use of color coated aluminum coil. Prior to installation, ensure that the construction site is dry and well-ventilated, avoiding moisture and chemical exposure. This minimizes the risk of corrosion and damage due to environmental factors.

Collision Protection

During transportation and installation, prevent color coated aluminum coil from collisions and friction, especially when handling larger coil sizes. Gentle placement and handling can significantly reduce the risk of surface damage.

Storage Requirements

Color coated aluminum coil stored for extended periods should be placed in a dry, ventilated area, preferably supported with horizontal padding to prevent deformation. Additionally, regularly inspect the storage area to ensure no moisture or contaminants ingress.

Cleaning and Maintenance

Regular cleaning and maintenance of color coated aluminum coil are crucial for preserving its appearance and performance. Use mild cleansers and soft cloths, avoiding corrosive or abrasive cleaners and tools. Furthermore, periodically inspect and repair any existing damage or defects to prevent further deterioration.

UV Protection

Long-term exposure to ultraviolet (UV) radiation may cause fading or discoloration of the surface color of color coated aluminum coil. Therefore, for outdoor installations, consider using coatings with UV resistance or adding additional protective measures to prolong the coil’s lifespan.

By adhering to the above usage and maintenance guidelines, we can ensure that color coated aluminum coil showcases its optimal performance in architecture and decoration. Whether used for exterior wall decoration, roof covering, or interior embellishment, color coated aluminum coil adds a unique charm and durability to our projects.