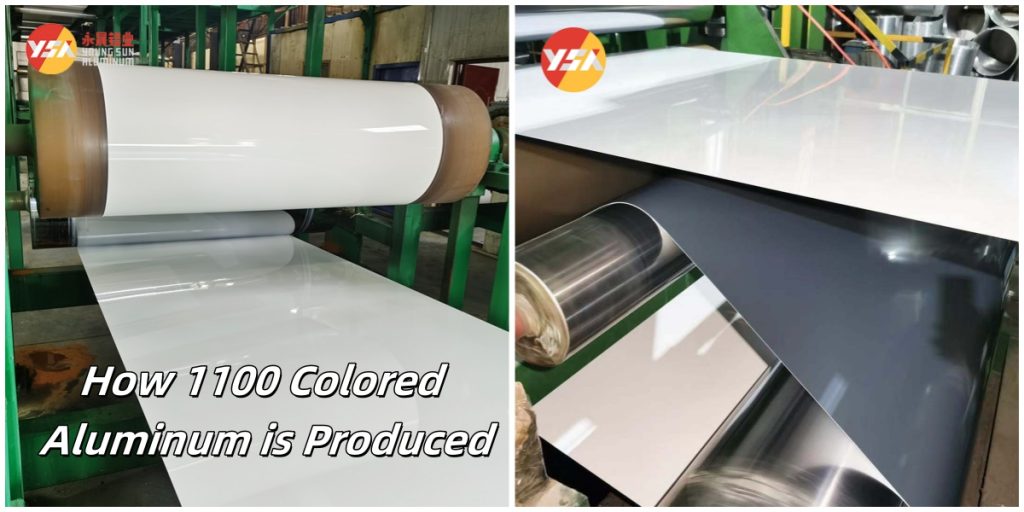

Due to its excellent comprehensive properties, 1100 alloy has become the preferred base material for architectural curtain walls, interior decoration, and home appliance panels. As a technical leader in the aluminum processing industry, this article systematically introduces the specialized production process of 1100 colored aluminum. This article will comprehensively explain the material properties, core processes, and surface treatment technologies.

1100 Colored Aluminum Base Material Characteristics

The outstanding performance of colored aluminum is deeply rooted in the DNA of its base alloy. 1100 alloy is widely regarded as the golden base material for colored aluminum production. Its core advantage lies in.

- Composition control: aluminum content ≥ 99.0%, iron (0.40-1.0%) and silicon (0.05-0.25%) as the main trace elements, and copper content ≤ 0.05-0.20%. High purity is critical to the success of subsequent processes.

- Corrosion Resistance: High-purity aluminum spontaneously forms a dense Al₂O₃ oxide film in air, providing a basic protective layer.

- Processability: Elongation ≥ 35%, deep drawing coefficient ≥ 2.0, enabling deep drawing and complex bending.

- Surface Consistency: The homogenized microstructure ensures coating adhesion ≥ 5 MPa.

- Excellent electrical and thermal conductivity: Second only to pure aluminum, making it advantageous in specific applications requiring heat dissipation or electrical conductivity.

1100 Colored Aluminum Core Production Process

Smelting and Purification

- Selected high-purity primary aluminum ingots and carefully sorted recycled aluminum are fed into large-scale melting furnaces.

- Key Process: Argon/nitrogen rotary degassing. Inert gas is introduced into the molten aluminum to efficiently remove dissolved hydrogen, eliminate porosity defects in the final sheet, and ensure material density.

Casting and Homogenization

- The purified molten aluminum is typically directly chill-cast into large slabs.

- Homogenization: The slabs are heated to 500-600°C and held at this temperature for several hours. This step eliminates casting segregation, dissolves iron-rich phases, and releases internal stress, significantly improving subsequent processing performance and the surface quality and consistency of the final product.

Hot Rolling

The heated slab undergoes multiple rolling passes, significantly reducing its thickness and initially refining the grain size, laying the foundation for basic mechanical properties.

Cold Rolling and Annealing

- After cooling, the hot-rolled coil undergoes multiple precision cold rolling passes at room temperature to achieve the precise target thickness and a mirror-smooth surface.

- Intermediate annealing may be required during the process: When the work hardening caused by cold rolling makes the material too hard, annealing is used to restore its plasticity, facilitating subsequent rolling or end-user forming. The final state is precisely controlled by the amount of cold rolling deformation and the final annealing.

Surface Pretreatment – The Key to the Success of Pre-painting

- Deep Cleaning: A strong alkaline or acidic degreasing agent thoroughly removes rolling oil, grease, and contaminants.

- Chemical Conversion/Chromizing or Chromium-Free Treatment: This is a crucial step for coating adhesion. A specific chemical solution forms a dense, nanoscale conversion coating with excellent adhesion and corrosion resistance on the clean aluminum substrate. It serves as a crucial “molecular bridge” between the aluminum substrate and the organic coating.

- Precision water washing and drying: Ensures the absence of any chemical residue and the surface achieves the required cleanliness and activity for the coating.

1100 Color Coil Coating Technology System

The coating choice directly determines the performance level and application scenarios of color-coated aluminum coil.

Roller Coating Principle

- Pretreated aluminum coils run on a high-speed continuous production line.

- A precisely controlled coating roller system evenly applies the liquid coating to both sides of the aluminum sheet.

- The coating then enters a multi-stage curing oven, where, under a strictly controlled temperature curve, the coating undergoes a cross-linking reaction, forming a strong, durable film. This process is highly efficient and provides exceptionally consistent quality.

PVDF Coating

- Material Composition: 70% PVDF Resin + 30% Acrylate.

- Coating Structure: Aluminum Substrate + 5-10μm Chrome Layer + 15-20μm Primer + 20-25μm Topcoat.

- Weather Resistance: Passes 3000h QUV Testing.

- Self-Cleaning: Contact Angle ≥ 90°.

- Applicable Standard: AAMA 2605.

PE Coating

- Material Characteristics: Polyester Resin System.

- Process Features: Single/Double Coat Process.

- Film Thickness: 18-25μm.

- Curing Conditions: 220°C x 60s.

- Applications: Interior Decoration, Appliance Panels.

Other Coatings

- Epoxy Coating: For Anti-corrosion Primer.

- Nano-Ceramic Coating: Improves Surface Hardness.

- Acrylic Coating: Offers performance between PE and PVDF, with a mid-range cost, finding application in specific markets.

Key Quality Control Points

Precision Curing

- The coated aluminum coil immediately enters a multi-zone curing oven, which can be tens of meters long.

- The temperature-time profile is a key parameter. The peak temperature reached by the sheet and the duration at that temperature must be precisely controlled to ensure sufficient crosslinking and curing of the resin. Insufficient temperatures will result in poor film properties; excessive temperatures may cause the film to become brittle, yellow, or degrade the mechanical properties of the substrate.

Cooling and Post-Processing

- After curing, the sheet must undergo a carefully controlled cooling section to avoid stress or deformation caused by rapid cooling.

- In-line lamination may be performed to protect the delicate surface from scratches during transportation and processing.

Strict Quality Inspection Throughout the Process

- Substrate Inspection: Thickness tolerance, sheet shape, and surface defects.

- Pretreatment Film Inspection: Film weight, uniformity, and adhesion.

- Film Thickness: Precisely controlled. For example, the total film thickness of PVDF after two coats and two bakes is typically ≥25μm.

- Colorimetry: A colorimeter is used to ensure high color consistency between batches and within rolls.

- Gloss: Meet design requirements.

- Adhesion: The cross-hatch method is a key indicator to ensure a strong, non-flaking film.

- Hardness: Tested using a pencil hardness test.

- Weathering Simulation: Long-term performance is predicted through salt spray testing, QUV/UVA accelerated aging testing, and other methods.

Only finished products that pass all testing standards are delivered to customers.

Application Technical Guidance

Preferred Curtain Wall Solution

- Recommended Coating: PVDF Dual-Coat System.

- Thickness Selection: Substrate ≥ 2.0mm + Coating ≥ 40μm.

- Installation Requirements: Allow 0.5mm/m for thermal deformation clearance.

Processing Precautions

- Shearing: Edge clearance ≤ 10% of the plate thickness.

- Bending: Internal fillet ≥ 1.5 times the plate thickness.

- Welding Process: Use 4043 welding wire and control heat input.