Aluminum air ducts play a crucial role in HVAC systems, facilitating the efficient and effective distribution of air throughout residential, commercial, and industrial spaces. Crafting quality aluminum air ducts requires precision, attention to detail, and adherence to industry standards. In this comprehensive guide, we’ll walk through the step-by-step process of producing aluminum air ducts, ensuring optimal performance and durability.

1.Material Selection

The first step in producing aluminum air ducts is selecting high-quality materials. Aluminum sheets with the appropriate thickness and grade are chosen based on the specific requirements of the project. The selected aluminum should possess excellent corrosion resistance, strength, and ductility to withstand the rigors of HVAC applications.

2.Cutting and Shaping

Once the aluminum sheets are sourced, they are cut into precise dimensions using specialized cutting tools such as shears or saws. The sheets are then shaped into the desired configuration for the air ducts. This may involve bending, folding, or rolling the aluminum to achieve the correct dimensions and angles.

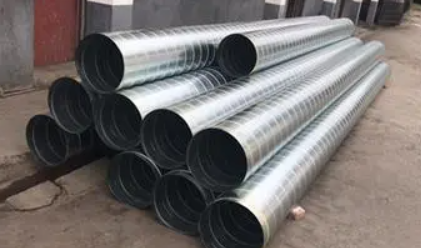

3.Assembly

After the aluminum sheets are cut and shaped, they are assembled into the final form of the air ducts. Various techniques such as welding, riveting, or using mechanical fasteners may be employed to securely join the individual components together. Careful attention is paid to ensure proper alignment and sealing to prevent air leakage.

4.Insulation (Optional)

In some cases, aluminum air ducts may require insulation to improve thermal efficiency and reduce condensation. Insulation materials such as fiberglass, foam, or mineral wool are applied to the interior surface of the ducts. The insulation is securely attached using adhesive or mechanical fasteners, providing added protection against heat loss or gain.

5.Quality Control

Quality control is an essential aspect of the production process to ensure that the aluminum air ducts meet industry standards and specifications. Each duct undergoes thorough inspection for dimensional accuracy, structural integrity, and surface finish. Any defects or imperfections are addressed promptly to maintain the quality of the final product.

6.Finishing Touches

Once the aluminum air ducts pass quality control, they undergo any necessary finishing touches. This may include surface treatment such as painting or coating to enhance corrosion resistance and aesthetic appeal. Proper labeling and packaging are also carried out to facilitate easy identification and handling during installation.

7.Testing and Certification

Before the aluminum air ducts are ready for deployment, they undergo rigorous testing to ensure optimal performance and compliance with regulatory standards. Various tests such as pressure testing, airflow testing, and fire resistance testing are conducted to validate the ducts’ integrity and functionality. Upon successful completion of testing, the ducts are certified for use in HVAC systems.

Conclusion

Crafting quality aluminum air ducts requires careful planning, skilled craftsmanship, and adherence to strict quality standards. By following the step-by-step process outlined in this guide, manufacturers can produce durable and efficient ductwork that meets the needs of diverse HVAC applications. From material selection to testing and certification, each stage of production plays a crucial role in delivering reliable air ducts for optimal indoor air quality and comfort.