In modern industry, mirror aluminum, thanks to its high reflectivity, lightweight construction, and corrosion resistance, has become a core material in lighting, electronics, and architectural decoration. Its production process integrates materials science and precision machining technology, with each step directly impacting the performance of the final product. This article will provide an in-depth analysis of the entire mirror aluminum production chain.

Base Material Selection for Mirror Aluminum Production

The core of mirror aluminum’s performance begins with the selection of the substrate. Currently, mainstream substrates fall into two categories.

High-purity aluminum substrates (1xxx series)

- Representative grades: 1070, 1085, 1090, aluminum purity ≥99%

- Advantages: Iron and silicon content <0.1%, low impurities, high oxide film transparency, and transmittance reaching 98% after polishing

- Limitations: Low mechanical strength, suitable for decorative applications

Aluminum-magnesium alloy substrates (5xxx series)

- Representative grades: 5005, 5754, magnesium content 3%-5%

- Advantages: Tensile strength >165 MPa, high elongation, lightweight and weather-resistant

- Applications: Load-bearing applications such as outdoor building curtain walls, automotive decoration, and LED heat sinks

Table1: Substrate Performance Comparison

| Substrate Type | Typical Grade | Reflectivity | Tensile Strength (MPa) | Applications |

| High-purity aluminum | 1085 | 90-95 | 100-120 | Interior decoration, lighting |

| Aluminum-magnesium alloy | 5754 | 85-90 | 165-265 | Building exteriors, automotive parts |

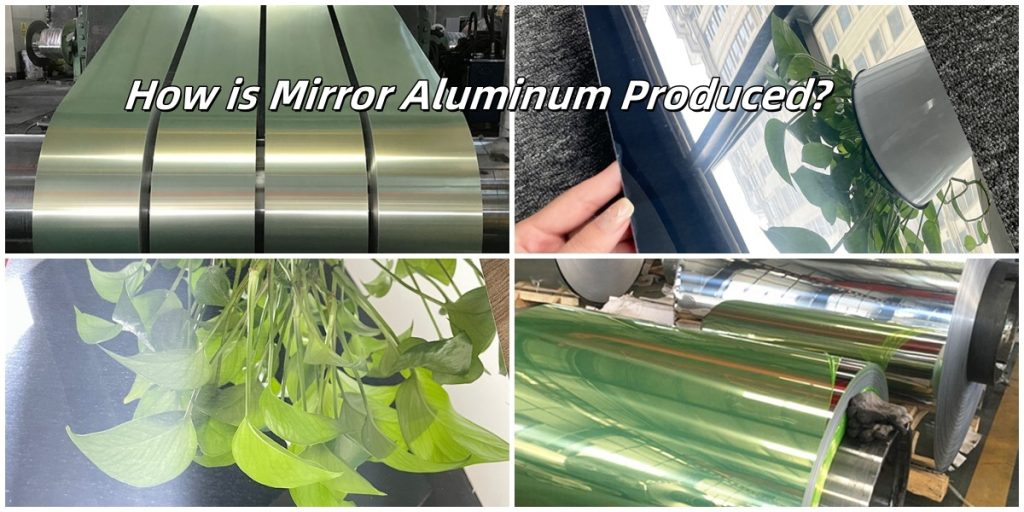

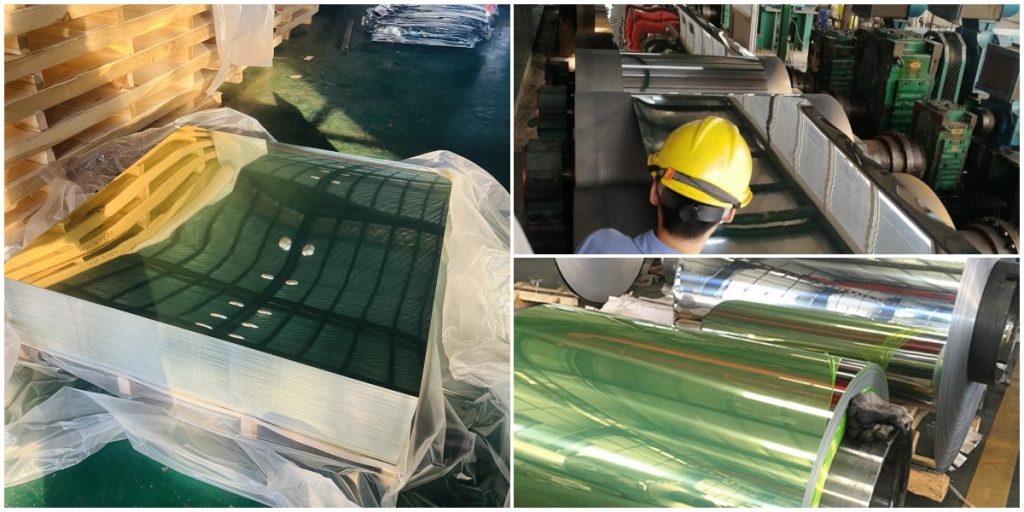

Core Processes from Aluminum Sheet to Mirror Finish

The processing of mirror aluminum requires three major stages: surface roughening, pressing, and precision polishing. Each step requires precise parameter control.

Step 1: Super-roughening Surface Treatment

- Sandblasting + Alkaline Etching: Micro-etching of both sides of the aluminum sheet using sodium hydroxide solution to achieve a roughness Ra of 1.45-1.67

- Purpose: Improve surface adhesion and prevent subsequent insulation layer loss

Step 2: Composite Lamination

- First Pre-pressing: Initially laminating the thermally conductive insulation sheet at 130°C and 5kg/cm² pressure

- Second Pre-pressing + Baking: Baking at 40°C for 12 hours to release internal stress

- Final Pressing: High-pressure pressing at 170°C to form the “aluminum substrate – insulation layer – copper foil” sandwich structure

Step 3: Mirror Finishing

- Rolling: The mainstream process! High-precision chrome-plated mirror rollers (hardness > 1000 HV) are rolled at a 20%-40% reduction ratio and a speed of 80-150 m/min

- Perchloric acid polishing fluid: 0.2 A/cm² current density, low temperature environment of 5-15°C, maintains high transmittance

- Smokeless polishing technology: The addition of corrosion inhibitors suppresses yellow smoke pollution, meeting environmental requirements

The new two-acid polishing fluid solves the pollution issues of the traditional three-acid process. While reflectivity is slightly lower, safety is significantly improved.

Standard Data for Finished Products of Mirror Aluminum

Mirror aluminum grades are defined by three key indicators: reflectivity, surface finish, and film performance.

Reflectivity Grading

- 800 Standard Mirror: Reflectivity 85%-90%

- 850 High Mirror: 90%-95%

- 890 Super Mirror: >95%

Surface Treatment Specifications

- Fluoropolymer Coating: Thickness 0.8μm, Hydrophobicity Angle >110°, Eliminates Water Spots

- Anodized Film: Thickness 6-12μm, Hardness ≥ Sapphire Grade (Mohs Hardness 9)

Durability Testing

- Salt Spray Test: >500 hours without corrosion

- High Temperature and Humidity (85°C/85% RH) Environment: 1000 hours without delamination

Table 2: Optical Performance Standards for Mirror Aluminum

| Base Material Purity | Polishing Process | Transmittance (%) | Surface Finish |

| 5N5 High-Purity Aluminum | Perchloric Acid Electrolytic Polishing | ≥98 | Level 1 |

| 1085 Industrial Pure Aluminum | Sulfuric Acid-Phosphoric Acid Polishing | 90 | Level 2 |

| 1070 Industrial Pure Aluminum | Diacid Smokeless Polishing | 85 | Level 3 |

Innovative Applications of Mirror Aluminum

With its superior performance, mirror aluminum is disrupting traditional industries.

Optoelectronics

- Mirror aluminum substrates for LEDs: Reflectivity > 98%, improving the luminous efficiency of COB packages by 30%

- Solar concentrators: Replacing silver-plated substrates, reducing costs by 50% and eliminating light decay issues

High-end manufacturing

- Consumer electronics: Laser engraving and anodizing of mobile phone backplates create customized metallic finishes

- Automotive decoration: Mirror aluminum honeycomb panels for new energy vehicle interiors reduce weight by 40%

Future trends in mirror aluminum

- Chromium-free passivation technology: Replacing the chromate process with a titanium-zirconium passivation film for environmentally friendly corrosion protection

- Composite substrates: Ceramic-mirror aluminum composite structures with thermal conductivity > 200W/mK address the heat dissipation bottleneck of high-power LEDs

- Intelligent production: CCD vision positioning and AI lamination parameter optimization keep product defect rates below 0.3%

The manufacture of mirror aluminum is a paradigm of precision materials engineering—from the selection of substrate genes to the control of nanoscale film layers, every step determines the interaction between light and metal. With breakthroughs by Chinese companies in high-purity aluminum rolling and pollution-free polishing, domestic mirror aluminum is shifting from a “follower” to a “leader.” Choosing mirror aluminum is more than just choosing a material; it’s choosing the future of light efficiency, energy savings, and industrial aesthetics.