Introduction

Aluminum discs, as a common aluminum product, are widely used in various industries, including aerospace, automotive manufacturing, and building decoration. However, when purchasing aluminum discs, several factors need to be considered to ensure the selection of suitable products. This article will discuss how to choose the right aluminum discs to help consumers make informed decisions.

Determine the Alloy Type

The performance and applications of aluminum discs are closely related to their alloy type. Common aluminum alloys include the 1000 series, 3000 series, 5000 series, etc., each with different characteristics. Choose the appropriate alloy type based on specific requirements such as strength and corrosion resistance.

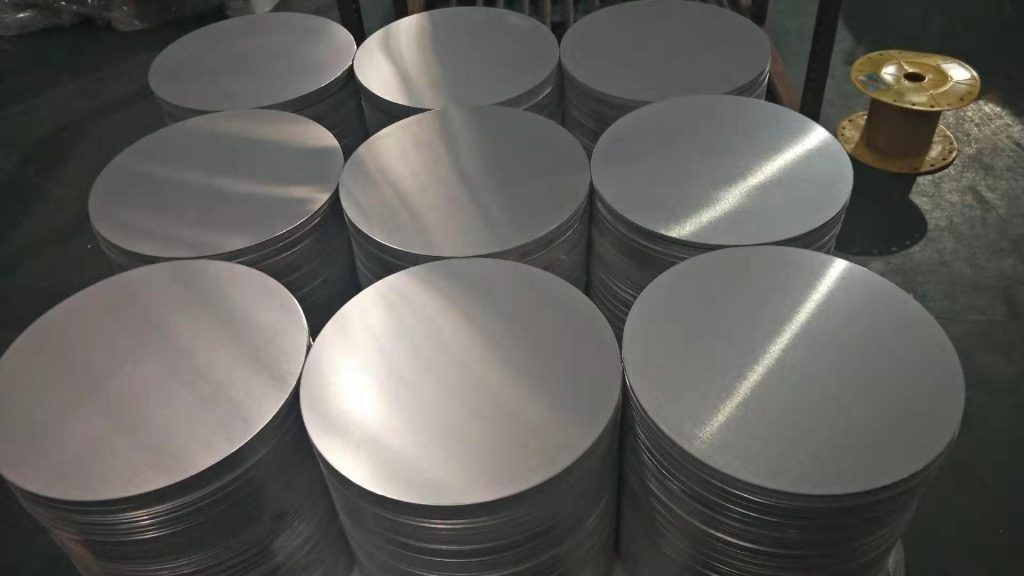

Specify Diameter and Thickness

The diameter and thickness of aluminum discs are crucial parameters to consider when making a purchase. The diameter determines the size of the discs, while the thickness affects their strength and application scenarios. Determine the suitable diameter and thickness based on the intended use.

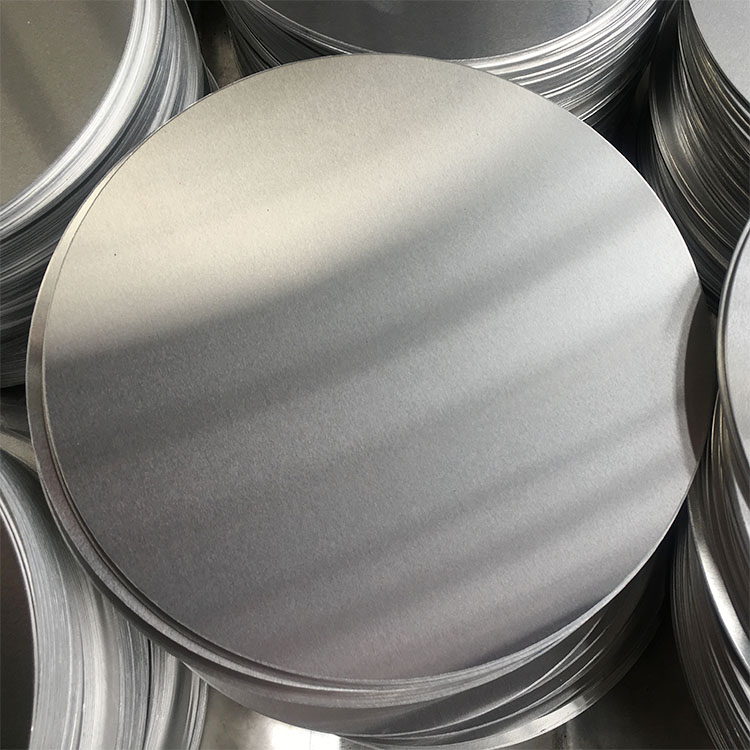

Consider Surface Treatment

The surface treatment of aluminum discs affects their corrosion resistance, decorative properties, or glossiness. Common surface treatments include anodizing, coating, polishing, etc. Choose the appropriate surface treatment method according to specific requirements.

Understand Production Processes

Different production processes will affect the quality and performance of aluminum discs. High-quality aluminum discs typically adopt advanced production processes such as continuous casting-rolling or extrusion processes to ensure uniformity and strength.

Choose a Reputable Supplier

Selecting a reputable supplier ensures product quality and service levels. Through customer reviews and understanding the supplier’s qualifications and production capabilities, choose a trusted supplier of aluminum discs.

Consider Price and Delivery Time

Finally, consider the price and delivery time. Compare the prices and delivery times of different suppliers to choose aluminum discs with high cost-effectiveness and timely delivery.

Conclusion

Choosing the right aluminum discs requires considering factors such as alloy type, diameter and thickness, surface treatment, production processes, supplier reputation, price, and delivery time. Only by comprehensively considering these factors can high-quality aluminum discs that meet specific requirements be selected, providing stable support for subsequent applications.