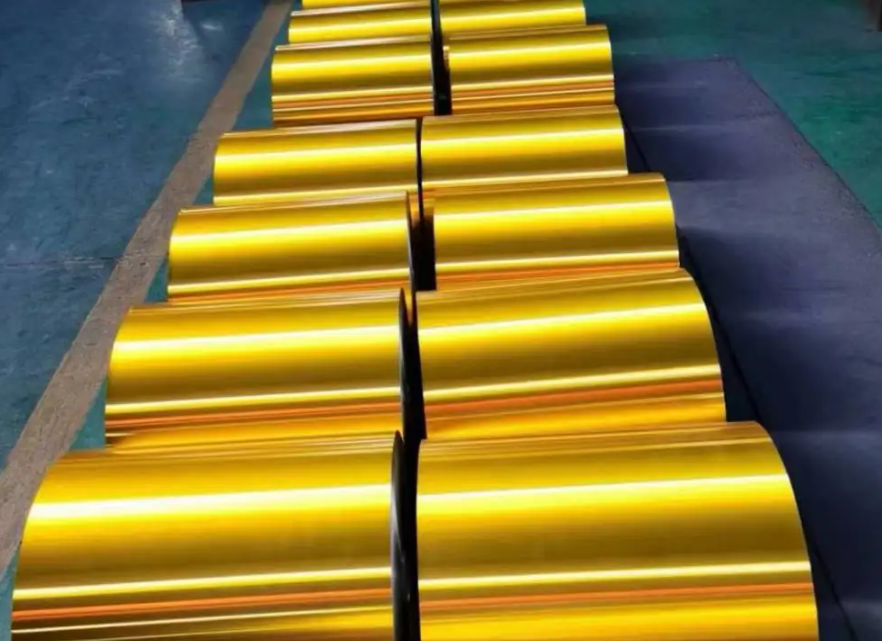

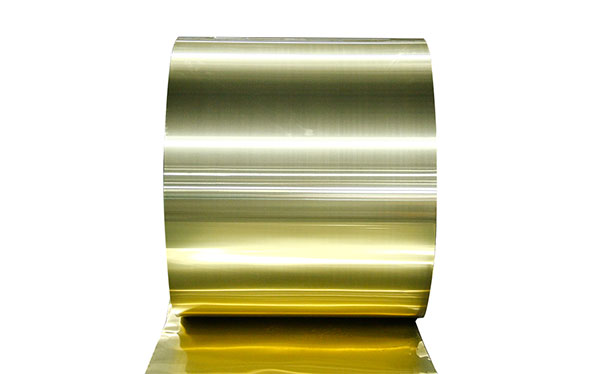

Coated aluminum foil, known for its excellent properties and wide range of applications, is highly valued across various industries. Selecting the appropriate coated aluminum foil requires careful consideration of multiple factors to ensure it meets specific application needs. Here are the key points to consider when choosing the right coated aluminum foil:

Application Requirements

First and foremost, the specific application should dictate the type and characteristics of the coated aluminum foil:

Food Packaging: Requires high barrier properties and heat resistance to ensure food freshness and safety. Coated aluminum foil effectively blocks oxygen, moisture, and other gases to prevent food spoilage.

Pharmaceutical Packaging: Needs high barrier properties and corrosion resistance to protect the active ingredients in pharmaceuticals from environmental factors, ensuring safety and efficacy.

Building Decoration: Requires aesthetic appeal, corrosion resistance, and weather resistance. Coated aluminum foil can be produced in various colors and patterns, providing both durability and visual appeal.

Automotive Industry: Needs high heat resistance and insulation properties to withstand high temperatures and complex conditions. Coated aluminum foil is widely used in automotive heat shields and engine covers.

Coating Types

Choosing the right type of coating is crucial for enhancing the properties of aluminum foil:

Polyester Coating: Offers good wear resistance and weather resistance, suitable for building decoration and outdoor applications. It maintains color and gloss over time.

Epoxy Coating: Provides excellent chemical corrosion resistance, suitable for pharmaceutical and chemical packaging. It protects the foil from chemical exposure.

Polyurethane Coating: Known for its high flexibility and wear resistance, suitable for food packaging and daily product packaging. It remains durable through frequent use and handling.

Anti-Static Coating: Suitable for electronic product packaging, preventing static electricity and electromagnetic interference. It protects sensitive electronic components.

Thickness Selection

Select the appropriate thickness of coated aluminum foil based on application needs:

Thinner Coated Foil: Suitable for applications requiring high flexibility and lightweight materials, such as food and pharmaceutical packaging. Thin foil is easier to process and use, reducing material waste.

Thicker Coated Foil: Suitable for applications requiring high strength and durability, such as building decoration and the automotive industry. Thick foil performs better under pressure and friction.

Environmental and Safety Considerations

Choose environmentally friendly and safe coated aluminum foil materials:

Food-Grade Coating: Ensure that the coated aluminum foil material meets food safety standards without releasing harmful substances, ensuring food safety.

Recyclable Materials: Opt for coated aluminum foil with high recyclability, reducing environmental pollution and resource waste, aligning with environmental protection standards.

Surface Treatment and Appearance

Select appropriate surface treatment and appearance based on application needs:

Smooth Surface: Suitable for applications requiring high gloss and aesthetic appeal, such as packaging and decorative materials. Smooth surface coated foil appears more attractive.

Matte Surface: Suitable for applications requiring low reflectivity and a soft appearance, such as electronic product packaging. Matte surface reduces light reflection and enhances visual comfort.

Patterns and Colors: Choose suitable patterns and colors based on branding and product requirements to enhance market competitiveness and visual appeal.

Supplier Selection

Choose reputable suppliers with quality assurance:

Quality Control: Ensure that the supplier has a strict quality control system in place, providing high-quality coated aluminum foil. Quality products reduce issues during production and improve efficiency.

Technical Support: Select suppliers that offer technical support and solutions to ensure optimal performance of coated aluminum foil in applications. Technical support can help resolve various issues encountered during use.

After-Sales Service: Choose suppliers that provide comprehensive after-sales service to address any problems that may arise during use promptly, ensuring continuity and stability in production.

Conclusion

Selecting the right coated aluminum foil involves considering factors such as application requirements, coating types, thickness selection, environmental and safety considerations, surface treatment and appearance, and supplier selection. By thoroughly understanding these key points and aligning them with specific application needs, you can ensure the selection of the most suitable coated aluminum foil, maximizing its performance and meeting various application demands.