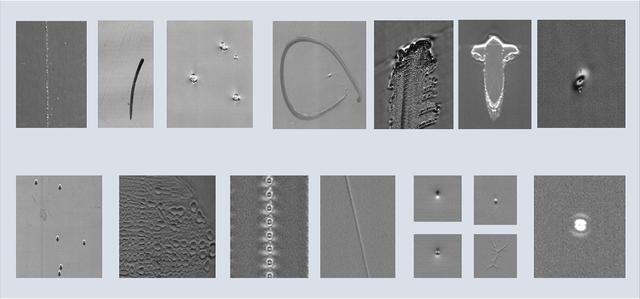

Pinhole

Pinhole is the main defect of aluminum foil. In the raw material, the dust on the roll, rolled oil, and even in the air reaches 6μm both the left and right into the roller seam will cause pinholes, so it is impossible for 6 μ m aluminum foil without pinholes, and we can only evaluate the size and size of it. Of course, using alloying and other means to improve the hardening properties of materials can also help to reduce pinholes. High quality hot rolled rolled 6 μ m aluminum foil pinholes can be under 100 / ㎡. When the casting and rolling material is well purified, the 6 μ m aluminum foil pinholes are below 200 pieces /㎡.

Roll seal, roll eye, uneven luster

It is mainly caused by roller aluminum foil defects, divided into three kinds of point, line and surface. The most prominent feature of three cycles appearing. The main causes of this defect are: incorrect grinding of roller; external damage roll: incoming material defect printing roll; roll fatigue; roll impact, skid, etc. All factors that can cause roll surface damage can cause harmful to aluminum foil rolling. Because the aluminum foil rolling roll surface smoothness is very high, the slight uneven luster will also affect its surface state.

Cockle

Due to the serious poor shape of the plate, wrinkles will form when the aluminum foil is rolled or unfolded, and the tension is not enough to flatten the foil surface. Highlights, bright marks, bright spots. The bright spots, bright marks and bright spots caused by the improper use of double oil, mainly because of the lack of double oil film strength, or uneven roll surface causes uneven rolling deformation, and the appearance of hemp skin or foreign body pressure. It is an effective measure to solve this defect to keep the supplied materials clean and the roll surface of the rolls even.

Thick difference of aluminum foil

The thickness difference is difficult to control is a feature of aluminum foil rolling. 3% thickness difference may not be difficult in the plate production, but very difficult in the aluminum foil production. The reason is that the thickness is thin, and other trace conditions can be affected, such as temperature, oil film, oil and gas concentration, etc. A rolling roll of aluminum foil can reach hundreds of thousands of meters, and the rolling time is about 10h. With the extension of time, the thickness difference is easy to form, and the means of thickness adjustment is only the tension speed. These factors all cause the thickness control difficulty of aluminum foil rolling, so the real control of the thickness difference within 3%, need many conditions to ensure, it is quite difficult.

Greasy dirt

Oil pollution refers to the excess oil on the surface of the aluminum foil after rolling, that is, the oil other than the rolled oil film. The oil surface of aluminum foil is more harmful than other rolling materials. First, because most of the finished aluminum foil as decoration or packaging materials, there must be a clean surface; second, the thickness is thin, easy to form bubbles after the annealing, and the use of more oil. Oil pollution defect is an important index to evaluate the quality of aluminum foil.

Water spots

Water spot refers to the white spot formed by water droplets on the foil surface before rolling, which affects the condition of the foil surface, and will cause band breaking in serious cases. Water spots are formed by water drops in the oil or water drops in the rolling mill falling on the foil surface. Controlling the water content and water source in the oil is the only measure to avoid water spots.

Vibration marks

Vibration refers to the periodic transverse waves on the surface of aluminum foil. There are two causes of vibration: one is formed by roller grinding, the period is about 10~20mm; the other is the rolling oil film continuous vibration, often produced in a speed range, the period is 5~10mm.

Tension lines

When the thickness reaches 0.015mm below, parallel stripes in the longitudinal form of aluminum foil, commonly known as tension line. The spacing between tension lines is about 5~20 mm, the less the tension, the wider the tension line, the more obvious the stripes. When the tension reaches a certain value, the tension line is very slightly or even disappeared. The smaller the thickness, the greater the possibility of tension, the greater the possibility of double rolling tension than the single. Increasing the tension and the roll roughness are the effective measures to reduce and eliminate the tension line, and the large tension must be based on a good plate shape.

Slotting

Opening seam is a unique defect of foil rolling, when rolling along the longitudinal straight split, often accompanied by wire line. The root cause of opening is the entrance side discount, often occurs in the middle, mainly due to the middle of the loose or poor roll. Severe openings cannot be rolled, and minor cracks in later split, which often causes a large amount of waste.

Air flue

At the rolling time, strips were crushed, with a droplet curve, a certain width, mild, uncrushed airway, white strips with dense pinholes. The presence of dense pinholes at the front and rear ends of the crushed aluminum foil is the main marker for judging the airway and other defects. Airway comes from raw materials, and it is very important to choose materials with low gas content as aluminum blank.

Roll the defect

Roll defect mainly refers to the loose roll or loose outside. It is ideal to obtain a loose volume inside, and sufficient tension is the condition for forming a certain tension gradient. Therefore, the quality of the roll ultimately depends on the shape of the plate, the loose inside and tight outside will form a horizontal edge, while the loose roll will form an ellipse, which will affect the later processing.

Conclusion

Although there are many kinds of defects in aluminum foil rolling, the final manifestations are: pinhole, roll eye, open seam, airway; the oil pollution, uneven gloss, vibration mark, tension line, water spot, light spot; the plate shape, wrinkle, discount, and poor drawing in the subsequent process; the thickness difference characterized by size. In essence, the unique defects of aluminum foil are only pinhole, other defects also have, but the severity of different or requirements are different.