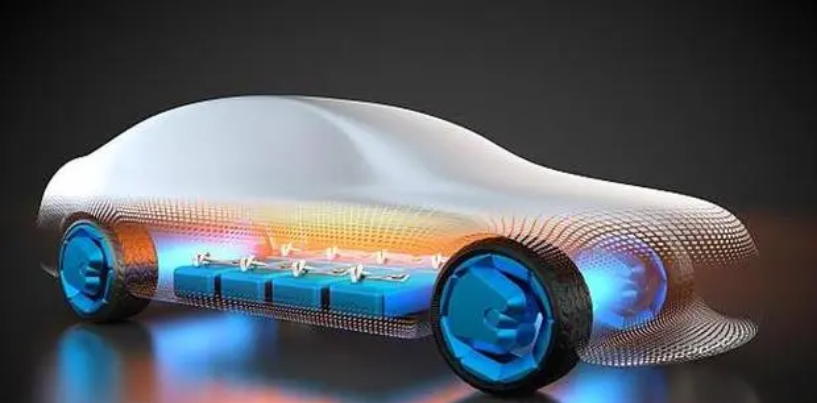

In the fast-evolving landscape of electric vehicles (EVs), every component plays a crucial role in shaping the efficiency, performance, and longevity of automotive batteries. Among these components, aluminum foil stands out as a silent hero, quietly powering the heart of EVs. Let’s delve into the significance of aluminum foil in automotive power batteries and how it contributes to the electrification revolution.

Conductivity Champion

At the core of automotive power batteries lies the need for efficient electrical conductivity. Aluminum foil boasts exceptional conductivity properties, providing a seamless pathway for the flow of electricity within the battery cells. This characteristic ensures minimal resistance, optimizing energy transfer and enhancing overall battery performance.

Lightweight Advantage

Weight reduction is a constant pursuit in automotive engineering, especially in EVs where every kilogram impacts range and efficiency. Aluminum foil offers a lightweight solution without compromising strength or durability. By incorporating aluminum foil, battery manufacturers can effectively reduce the overall weight of battery packs, contributing to extended driving ranges and improved energy efficiency.

Corrosion Resistance

Operating within demanding automotive environments, battery components must withstand various challenges, including corrosion. Aluminum foil exhibits innate resistance to corrosion, ensuring the longevity and reliability of automotive power batteries. This resistance safeguards against degradation over time, maintaining consistent performance throughout the battery’s lifecycle.

Malleability and Adaptability

Flexibility in design and manufacturing is paramount for accommodating diverse battery architectures and configurations. Aluminum foil’s malleability allows it to be easily shaped and tailored to fit specific requirements, enabling seamless integration into various battery designs. Whether in cylindrical, pouch, or prismatic cell formats, aluminum foil proves adaptable, facilitating efficient assembly and enhancing overall battery performance.

Cost-Effectiveness

In an industry focused on scalability and cost efficiency, aluminum foil emerges as a cost-effective solution for automotive power batteries. With abundant availability and streamlined manufacturing processes, aluminum foil offers a competitive advantage over alternative materials. This cost-effectiveness translates into more accessible EVs for consumers and a sustainable pathway towards widespread electrification.

Driving the Future

As the automotive industry continues its transition towards electrification, the role of aluminum foil in powering automotive batteries becomes increasingly indispensable. Its unmatched conductivity, lightweight nature, corrosion resistance, malleability, and cost-effectiveness position aluminum foil as a cornerstone of EV technology. Embracing aluminum foil signifies embracing innovation, efficiency, and sustainability in the pursuit of a greener automotive future.

In conclusion, aluminum foil may appear unassuming, but its impact on automotive power batteries is profound. As EVs become the norm rather than the exception, the significance of aluminum foil will only continue to grow, driving forward the electrification revolution one charge at a time.