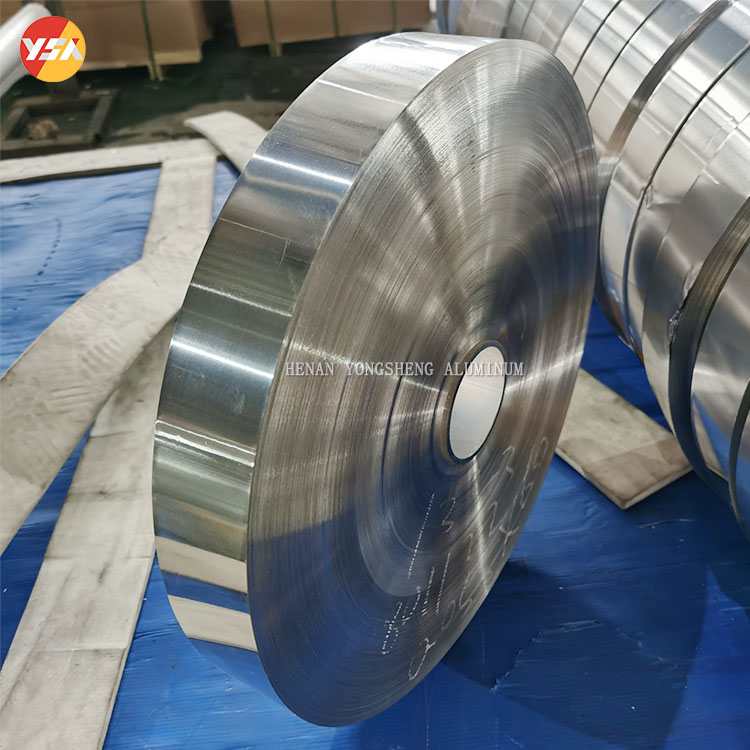

Aluminum foil is a high-quality packaging material widely used in food, pharmaceuticals, electrical insulation, and construction industries. To ensure the quality and performance of aluminum foil during cutting, specific key factors must be taken into account. This article will discuss important things to remember when cutting aluminum foil to ensure safety, efficiency, and quality products.

Equipment Selection and Maintenance

The first step in cutting aluminum foil is choosing the appropriate cutting equipment. Different cutting machines are available. Operators should choose the right one based on the foil’s characteristics and production requirements.

The choice of blades is particularly crucial—sharp blades are essential to cut the foil without tearing or distorting it. Regularly check and maintain the equipment, especially the cutting system. Replace or sharpen blades quickly to keep cutting accurate and efficient. Also, make sure conveyor belts and guides are working properly to avoid jams or issues while cutting.

Material Specifications and Settings

Before cutting aluminum foil, make sure to check its width, thickness, and material type specifications. Different thicknesses and types require specific settings, including cutting speed, pressure, and blade angle. Operators should adjust these parameters according to the material’s properties to ensure smooth, burr-free cuts.

Correct blade angles and cutting speeds enhance cutting quality and prolong blade lifespan, lowering production expenses. Maintaining consistent tension during cutting is also key to achieving uniform results.

Maintaining a Clean Environment

The cutting process for aluminum foil is sensitive to environmental conditions, making cleanliness a top priority. Regularly clean the production area to remove dust, grease, and other contaminants to prevent material contamination. A clean environment enhances the appearance and quality of the final product while minimizing the potential for mechanical failures.

When cleaning, don’t use detergents that leave residue. Make sure tools and equipment touching the foil are clean and free of contaminants.

Controlling Temperature and Humidity of Cutting Aluminum Foil

The properties of aluminum foil can be affected by high temperatures or high humidity. Too much heat can cause materials to expand, and high humidity can lead to rust or changes in shape.

Therefore, it is important to control the working environment’s temperature and humidity during cutting. Ideally, the working environment should be around 20°C (68°F) with humidity levels between 40% and 60%. Air conditioning or dehumidifiers can improve cutting process quality and stability by creating optimal conditions.

Safety Operating Procedures

Operating cutting equipment involves certain risks, making safety a paramount concern. Operators must wear gloves, safety goggles, and proper clothing to reduce the chance of getting injured. Before operating the equipment, make sure that all personnel are trained and familiar with operational procedures and emergency protocols. Regular safety training and drills should be conducted to enhance employee awareness, ensuring that everyone can remain vigilant and respond to potential emergencies effectively.

Product Packaging and Storage

Cut aluminum foil should be packaged promptly to protect it from external influences. When packaging, make sure to lay the foil flat and avoid folding or twisting, as it can affect usability. Store aluminum foil in a dry, cool place away from sunlight and humidity to prevent damage.

Proper storage is important. Thoughtful warehouse management, such as using shelving or specialized storage boxes, can improve retrieval efficiency and reduce waste.

Conclusion

In summary, cutting aluminum foil is a detailed process that benefits from careful consideration of various factors. Using the right tools can help cut aluminum foil better.

Managing the workspace is important too. Safety should always come first. Keeping the area clean is essential. Proper storage also helps improve efficiency and quality.

Additionally, businesses should continuously improve their cutting processes and equipment to adapt to the increasing market demand. Attention to detail will lead to greater success and assurance in your aluminum foil production efforts.