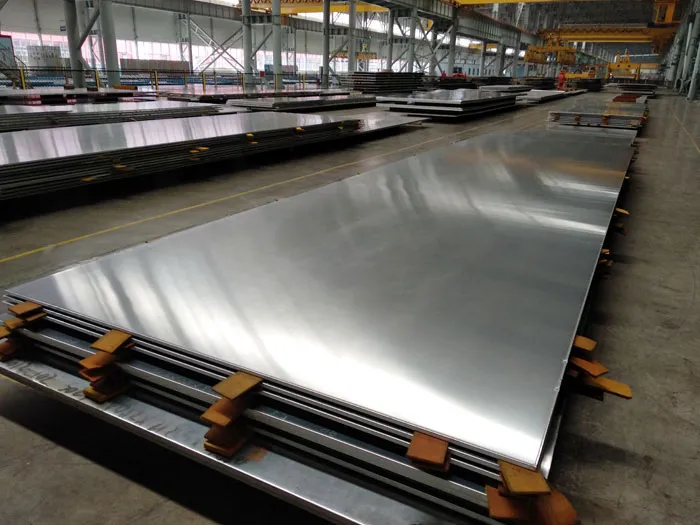

What Is Marine Aluminum?

Marine aluminum is an aluminum boat material. Compared with traditional steel, marine aluminium has excellent properties such as low density, high strength and corrosion resistance. It usually adopts aluminum alloy composition that is suitable for the ship operating environment. For example, some commonly used marine aluminum alloys include 5000 series aluminum, 6000 series aluminum and 7000 series aluminum. These alloys are suitable for different types of ships, such as fast patrol boats, yachts, ship bottom plates, etc.

What Alloys Are Used In Aluminum Sheets For Boat Building?

The material selection of marine grade aluminium sheet is relatively strict. At present, aluminum alloy products such as 5052, 5083, 5086, 5454, 5754, and 6061 are mostly used. In practical applications, the advantages of marine aluminum alloys are very obvious. Firstly, it has a small specific gravity, which can reduce ship weight, save energy consumption and increase load capacity; secondly, it has good corrosion resistance, which reduces oiling and other expenses and extends its service life; thirdly, it has good welding and processing formability, which is convenient for later processing; finally, aluminum The waste materials are easy to recycle and can be recycled. At the same time, they do not burn and are safe in case of fire.

- 5052 aluminum alloy: used to manufacture hulls, decks, masts, ship shells, marine valves, ship electrical system components, lifeboats, ship identification plates, etc.

- 5083 aluminum alloy: Alloy 5083 aluminum is the best aluminum for salt water and the best aluminum for marine use. It is an ideal choice for manufacturing ship bottom plates, bottom beams, decks, hatch covers, deflectors, fuel tanks and other offshore structures.

- 5086 aluminum alloy: Similar to 5083, 5086 aluminum also has excellent corrosion resistance and strength. It is commonly used in the manufacture of hull walls, ship superstructures and other onboard structures.

- 5454 aluminum alloy: commonly used in hull plates of various types of ships such as ocean ships, yachts, oil tankers, fishing boats, etc.

- 5754 aluminum alloy: commonly used in shipbuilding structures, hull plates, deck cladding and other components that require lightweight and corrosion resistance. As well as parts such as hull shells, ship decks, ship cabin partitions and cargo holds. In addition, 5754 aluminum sheet is also commonly used in the manufacture of ship internal equipment and accessories, such as ship fuel tanks, water tanks, pipes and ship accessories.

- 6061 aluminum alloy: 6061 aluminum is less used in ship construction, but it also has its value in some specific applications, such as ship’s external structure, ship decoration parts, internal partitions, ship equipment and components, etc.

Why Can Aluminum Be Used Near Water?

Aluminum may not be the best for continuous submersion, but it is a popular material for boats, docks, pontoons, job site furniture and ladders because it is both light and strong. When raw aluminum is exposed to air and water (rather than being constantly immersed in water), the aluminum oxide that forms on the surface prevents further corrosion. Ordinary 3000 series aluminum alloys will oxidize rapidly in marine environments. If you are purchasing aluminum items for use in or around the water, make sure you are purchasing marine aluminum, whether it is the aluminum 5000 series or some of the manufacturers’ aluminum 6000 series alloy products. With care and maintenance, these grades provide a long service life for aluminum objects near water.

Selection Principles for Marine Aluminum:

Aluminum marine is one of the emerging fields of aluminum alloy products, and it is also a key direction for the transformation and upgrading of many aluminum processing companies. Since aluminium marine is used in marine vessels and other fields, it has stricter process requirements and performance standards than other ordinary aluminum alloy products. It can be mainly divided into four aspects:

- High specific strength and specific modulus: The structural strength and size of the ship are closely related to the yield strength and elastic modulus of the material. Since the elastic modulus and density of aluminum alloys are roughly the same, the addition of alloy elements has little effect, so in Increasing the yield strength within a certain range is effective in lightening the ship structure. It is often difficult for high-strength aluminum alloys to have both excellent corrosion resistance and weldability. Therefore, marine aluminum alloys are generally medium-strength, corrosion-resistant and weldable alloys.

- Excellent welding performance: At present, automatic argon arc welding method is mainly used in ships. Good weldability means that the tendency of aluminum alloy to form cracks during welding is smaller, which means that aluminum alloy must have good welding crack resistance. . Because the lost welding performance cannot be restored by heat treatment again under shipbuilding conditions.

- Excellent corrosion resistance: Ship structures are used in somewhat harsh seawater media and marine environments. Therefore, corrosion resistance is one of the main signs of aluminum sheet for boat.

- Good cold and hot forming properties: Because ship manufacturing requires a variety of cold processing and hot processing, aluminum for marine use must be easy to process and form, without crack defects, and still meet the strength and corrosion resistance requirements after processing.

Other Materials vs Marine Grade Aluminum:

Steel:

Marine aluminum offers significant advantages over steel in terms of weight reduction, corrosion resistance and ease of fabrication. Steel requires specialized anti-corrosion methods such as coatings and sacrificial anodes, while the inherent corrosion resistance of marine aluminum reduces the need for extensive maintenance. Additionally, aluminum’s lighter weight helps improve fuel efficiency and ship performance.

Glass Fiber:

Fiberglass is another material commonly used in marine applications. While fiberglass boats offer cost savings and resist some forms of corrosion, marine aluminum offers superior strength, durability, and impact resistance. Aluminum is also easier to repair than fiberglass, which may require specialized techniques to repair the damage.

Wood:

Traditional wooden boat construction has historical significance, but marine aluminum is popular for its modern advantages. Aluminum offers better durability, lower maintenance requirements and greater design flexibility than wood. Aluminum boats also eliminate concerns associated with rot, splintering and insect infestation that are common with wooden structures.

FAQ:

Is 6063 Aluminum Marine Grade?

No, 6063 aluminum alloy is not one of the marine grade aluminum alloys commonly used in aluminum boat manufacturing. Because of its relatively low strength, it is mainly used in construction and some non-structural applications, such as door and window frames, pipes, profiles, etc.

What Is The Best Aluminum For Saltwater Boats?

For ships operating in saltwater environments, 5083 aluminum alloy is widely considered to be one of the most suitable materials. 5083 aluminum has excellent corrosion resistance, high strength properties, and can resist seawater corrosion and oxidation. There are also other alloys that can be used in shipbuilding in saltwater environments, such as 5086 aluminum alloy and 5456 aluminum alloy.

Does Marine Grade Mean Waterproof ?

“Marine grade” usually refers to products or materials that have good performance and durability in the marine environment. They are usually specially designed and manufactured to cope with the requirements of marine environments such as saltwater corrosion and high wind and waves. However, just having a marine grade logo does not mean it is absolutely waterproof.