The general production process of corrugated aluminum sheets includes the following steps:

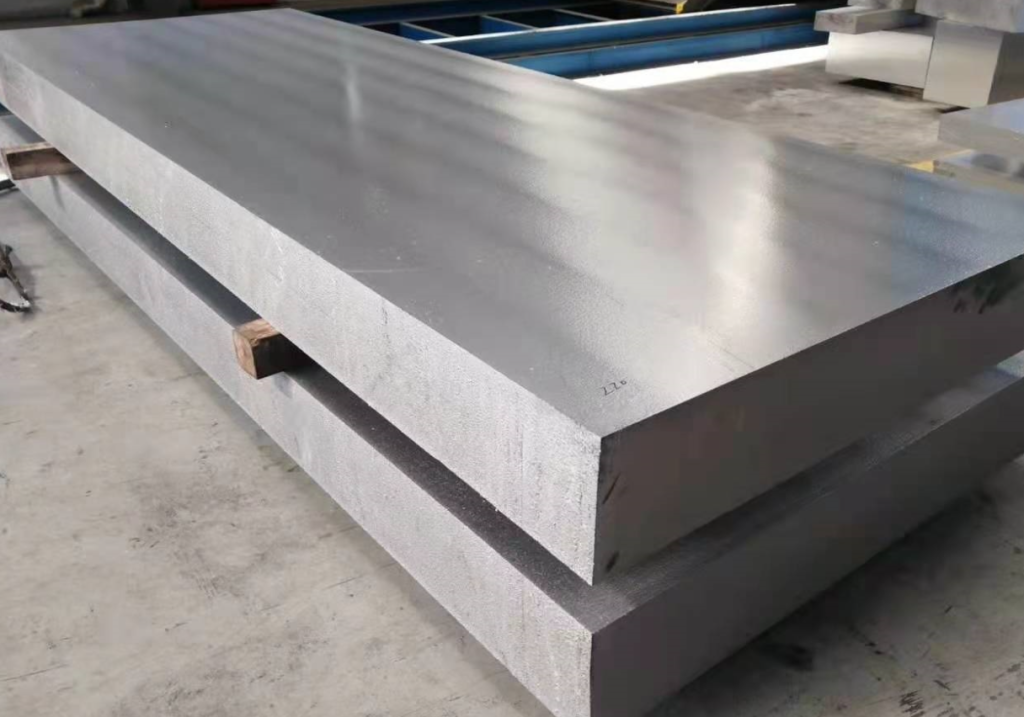

Raw material preparation

Aluminum alloy sheets are used as the raw material for corrugated aluminum sheets. Common aluminum alloys include 1000 series, 3000 series and 5000 series aluminum alloys.

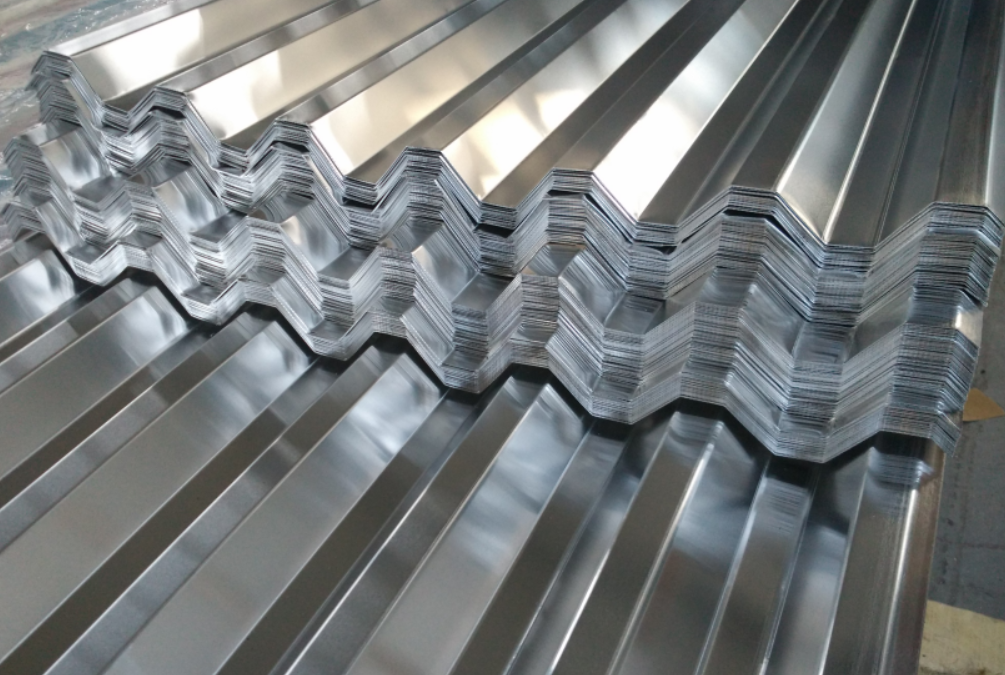

Processing and forming

First, cut the aluminum alloy sheet, and then stamp it into corrugated stripes on a corrugated machine. Generally, different corrugated stripes can be customized according to customer requirements, and then cold work the corrugated aluminum sheet into the desired shape and size.

Surface treatment

After the production of corrugated aluminum sheets, surface treatment is generally required to improve their corrosion resistance and decorative properties. Common chemical treatment methods include oxidation, galvanizing, electrophoretic painting, etc., and surface coating can also be carried out through painting, spraying, and other methods.

Quality inspection

After production is completed, quality inspection is required to ensure the qualification rate of each batch of products. The main inspection items include dimensional accuracy, appearance quality, surface treatment, corrosion resistance, mechanical properties, and other indicators.

Packaging and shipment

After the production of corrugated aluminum plates is completed, they need to be sorted, packaged, and shipped. Generally, auxiliary packaging materials such as sponge boards and wooden pallets are used for protection to prevent damage to corrugated aluminum sheets caused by friction and vibration during transportation.

Overall, the production process of corrugated aluminum sheets is relatively simple, but strict control is required at every step to ensure that the quality of the products produced meets customer needs and standards.