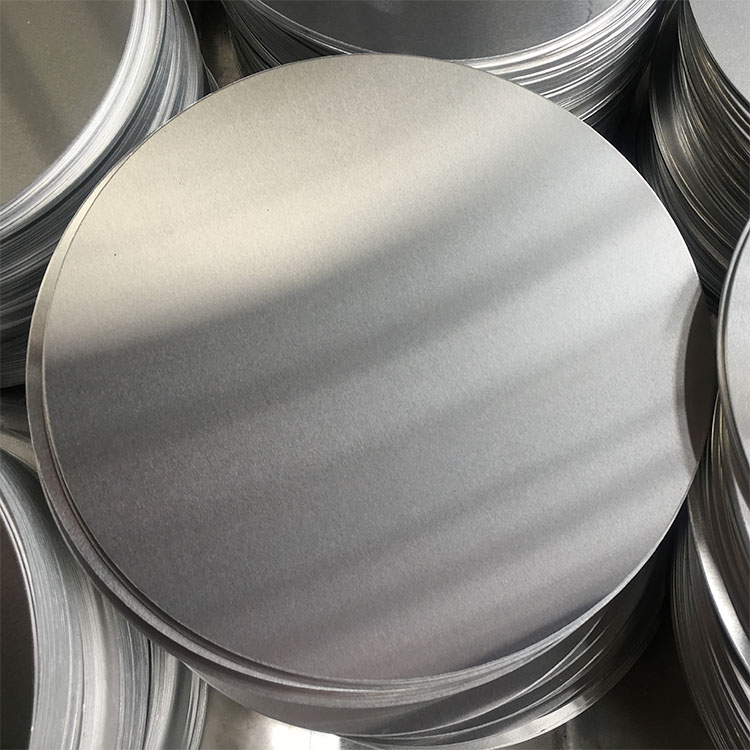

Aluminum circles are versatile metal disks used in various industries for applications such as cookware, lighting fixtures, signage, and more. The size of aluminum circles is a crucial consideration, as it determines their suitability for specific uses. In this comprehensive guide, we’ll explore the sizes of aluminum circles and factors to consider when selecting the right size for your needs.

Common Sizes of Aluminum Circles

Aluminum circles are available in a wide range of sizes, with common diameters typically ranging from a few inches to several feet. Some standard sizes include:

1. Small Diameter: Small aluminum circles may have diameters as small as 1 inch (25.4 mm) or even less. These are often used in applications requiring miniature components or precise dimensions.

2. Medium Diameter: Medium-sized aluminum circles typically range from 6 inches (152.4 mm) to 12 inches (304.8 mm) in diameter. They are commonly used in cookware, lighting fixtures, and small-scale fabrication projects.

3. Large Diameter: Large aluminum circles can have diameters exceeding 24 inches (609.6 mm) or more. These larger sizes are often utilized in industrial applications such as tank heads, machine parts, and architectural elements.

Factors to Consider When Selecting Aluminum Circle Sizes

When choosing the size of aluminum circles for your specific application, several factors should be taken into account:

1. Application Requirements: Consider the intended use of the aluminum circles and the dimensions required for your project. Ensure that the selected size meets the dimensional specifications and performance requirements of your application.

2. Material Thickness: Aluminum circles are available in various thicknesses, and the size may influence the thickness needed for structural integrity and performance. Thicker circles may be required for larger diameters or heavy-duty applications.

3. Fabrication Processes: Take into consideration the fabrication processes involved in your project, such as cutting, bending, or stamping. Ensure that the chosen size of aluminum circles is compatible with the fabrication equipment and techniques used.

4. Cost and Material Efficiency: Optimize material usage and minimize waste by selecting aluminum circle sizes that align with your project’s requirements while maintaining cost-effectiveness.

Conclusion

The size of aluminum circles plays a critical role in determining their suitability for specific applications. By understanding common sizes and considering factors such as application requirements, material thickness, fabrication processes, and cost efficiency, you can select the right size of aluminum circles to meet your project needs effectively. Whether it’s for cookware, industrial components, or decorative purposes, choosing the appropriate size ensures optimal performance and functionality.