Aluminum Strip For Conduct

Aluminum strip for conduct possesses excellent electrical conductivity properties and is made from a high-quality aluminum alloy. Henan Yongsheng is a manufacturer that produces exceptional aluminum strip for conduct. With 18 years of experience in the industry, Henan Yongsheng Aluminum Co., Ltd. is a factory that specializes in manufacturing aluminum sheets, coils, foils, and strips. Located in Gongyi City, Henan Province, the company’s main focus is on producing and developing aluminum products, including checker plates, color-coated sheets, and embossed sheets. Covering an impressive area of 300,000 square meters and employing 3,200 people, their commitment lies in providing exceptional aluminum materials.

Product Introduction

Aluminum strips possess excellent conductivity and exhibit a combination of low density and high strength, comparable to or even surpassing high-quality steel. Aluminum strip for conduct demonstrate exceptional plasticity, allowing for versatile shaping into various profiles. Additionally, aluminum exhibits outstanding electrical conductivity, thermal conductivity, and corrosion resistance. Certain aluminum alloys can undergo heat treatment to achieve favorable mechanical properties, physical attributes, and enhanced resistance to corrosion. Commonly used alloys for conductive aluminum strips include 1060, 1100, 3003, and 3004.

In terms of electrical conductivity, aluminum ranks behind silver, copper, and gold. Although its conductivity is approximately two-thirds that of copper, its density is only one-third of copper’s. As a result, when carrying the same electrical load, aluminum weighs only half as much as copper.

The oxide film that naturally forms on the surface of aluminum serves as a protective barrier against corrosion and provides a certain level of insulation. This has led to the widespread utilization of aluminum in industries such as electrical manufacturing, wire and cable production, and the radio industry.

Specifications

| Alloy | 1100, 1050, 1070, 3003, 3004, 3105, 3005, 5005, 5052, 5754,etc |

| Temper | T4,T5,T6,T651,T652,T112,T351 |

| Thickness(mm) | 0.3-3mm |

| Width(mm) | 40mm – 90mm |

| MOQ | 1 Tons |

| Delivery | Ready stock: 7-10 days, future goods: 15-30 days |

| Price term | EXW,FOB,CIF,CFR,CNF,etc. |

| Payment | L/C,T/T,Western Union,etc. |

| Certificates | ISO9001&GS&ROHS&FDA&TUV&ISO&GL&BV,etc. |

Product Application

The aluminum strip for conduct commonly utilize the 1060, 1100, 3003, and 3004 aluminum alloys. These alloys are known for their high electrical conductivity and good formability characteristics. The 1060 alloy is well-suited for applications that prioritize conductivity without requiring high strength, such as electronic components and capacitor strips. Similarly, the 1100 alloy is used in applications where electrical conductivity is crucial, such as power transmission lines and bus bars. The 3003 alloy strikes a balance between electrical conductivity, mechanical strength, and corrosion resistance, making it suitable for heat exchangers and air conditioning systems. The 3004 alloy, with increased strength, is used in applications that require formability and moderate strength, such as automotive heat exchangers and beverage can lids. The choice of alloy depends on the specific requirements of conductivity, strength, and formability for a particular application.

Product Advantages

- Superior Electrical Conductivity: Aluminum has a relatively high electrical conductivity, coming in just behind gold, copper, and silver. It is ideal for many electrical and electronic applications because it enables the efficient transfer of electrical current.

- Economical: Aluminum is typically less expensive when compared to other conductive metals like copper or silver. In conductive applications, aluminum strip’s reduced material cost results in overall cost benefits.

- Good Thermal Conductivity: Aluminum has good thermal conductivity in addition to electrical conductivity. This feature allows for efficient heat dissipation in conductive applications, which makes it appropriate for cooling systems, heat sinks, and thermal management.

- Lightweight: Compared to copper and other conductive materials, aluminum has a low density, which makes aluminum strips substantially lighter. Because it is lightweight, handling, installation, and shipping are made easier, which lowers total expenses.

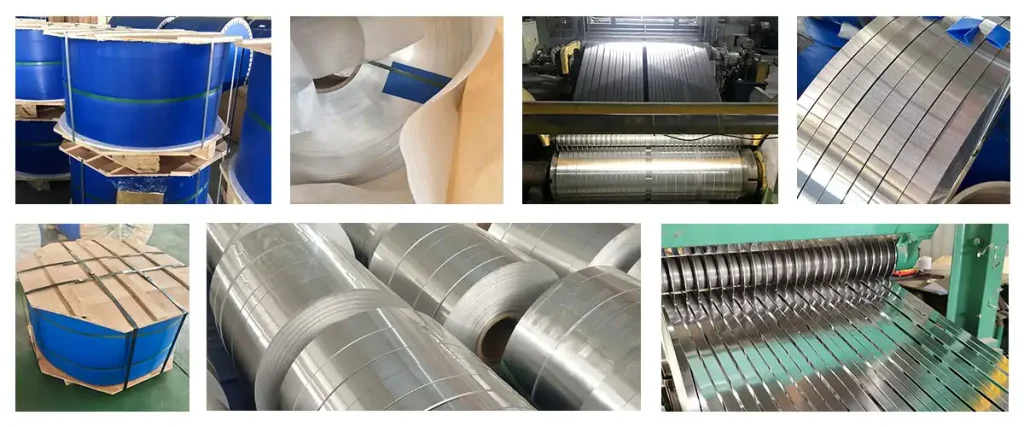

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

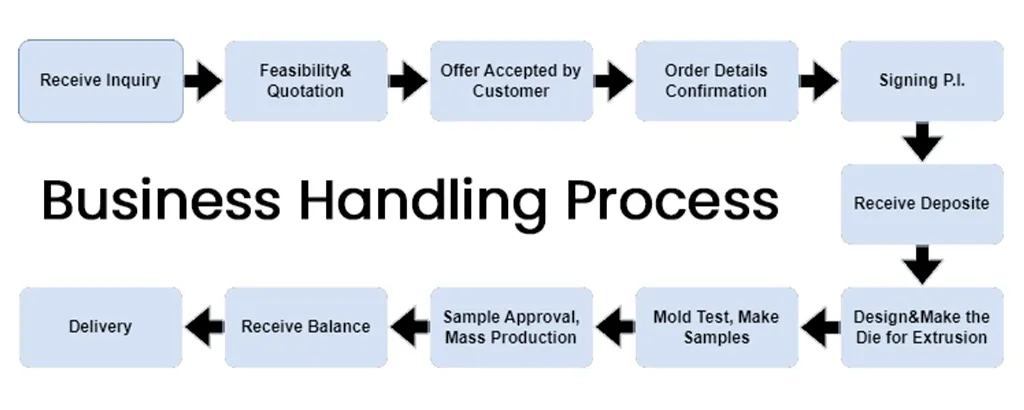

Business Handling Processes