Hot Rolled Aluminum Sheet

Alloy: 1000, 3000, 5000, 6000 series

Temper: O-H112, T3-T8, T351-T851

Width: 100mm-2600mm

Thickness: 0.1 mm- 350 mm

Delivery: Ready stock: 7-10 days, future goods: 15-30 days

Price Terms: FOB, CIF, CFR, CNF, etc.

What is Hot Rolled Aluminum Sheet?

Hot rolled aluminum sheet refers to an aluminum sheet made by heating, rolling, cooling and other processes of aluminum billet at high temperature. The manufacturing process of hot-rolled aluminum sheets plates mainly includes aluminum billet pretreatment, heating, rolling, cooling, cutting and other links.

Aluminum Sheet Hot Rolled Production Process:

First, the aluminum billet undergoes surface cleaning, cutting, oxide scale removal and other pre-treatment processes to ensure the surface quality and dimensional accuracy of the aluminum billet. Then, the aluminum billet is heated to a certain temperature to bring it to a plastic state for easy rolling. Next, the heated aluminum billet is rolled through a rolling mill to form the required plate thickness and width. After rolling is completed, the aluminum plate is cooled to fix its structure and properties. Finally, the cooled aluminum plate is cut into the required size and shape according to the customer’s requirements. The entire hot rolled aluminum sheet manufacturing process requires strict control of process parameters in each link to ensure the quality and performance of the aluminum sheet.

Hot Rolled Aluminum Sheet Specifications:

| Hot Rolling Aluminum Sheet | |||||

| Series | Alloy | Temper | Thickness | Length | Width |

| 1000 Series | 1050, 1060, 1070, 1100 | F, O, H12, H14, H16, H18, H111, H112 | 0.10mm-350mm | Any | 100mm-2600mm |

| 3000 Series | 3003, 3004, 3005, 3105 | F,O, H12, H14, H16, H18, H111, H112 | 0.10mm-350mm | Any | 100mm-2600mm |

| 5000 Series | 5052, 5A02,5A03, 5A05, 5083, 5754, 5086, 5182 | F, O, H12, H14, H16, H18, H111, H112 | 0.10mm-350mm | Any | 100mm-2600mm |

| 6000 Series | 6061, 6063 | F, O, H111, H112, T6 | 0.10mm-350mm | Any | 100mm-2600mm |

Hot Rolled Aluminum Sheet vs Cold Rolled Aluminum Sheet:

- Manufacturing temperature: Hot rolled aluminum sheets are manufactured at high temperatures, while cold rolled aluminum sheets are manufactured at or near room temperature. Therefore, hot-rolled aluminum sheets have higher plasticity, but are also more prone to grain enlargement.

- Surface quality: Hot-rolled aluminum sheets usually have a rougher surface, while cold-rolled aluminum sheets have a smooth surface.

- Mechanical properties: Due to the difference in manufacturing temperature, hot-rolled aluminum sheets generally have lower tensile strength and hardness, while cold-rolled aluminum sheets have higher tensile strength and hardness.

- Application fields: Hot rolled aluminum sheets are often used in applications that do not require high mechanical properties and require greater plasticity, such as construction, container manufacturing, etc. Cold rolled aluminum sheets are usually used in applications that require higher surface quality and mechanical properties, such as automobile manufacturing and electronic product casings.

Characteristics of Hot Rolled Aluminum Sheet:

1. Hot rolled aluminum sheets have low energy consumption, good plasticity, low deformation resistance, no obvious work hardening, and are easy to roll.

2. Hot rolling usually uses large aluminum ingots and large reductions. The production pace is fast and the output is large.

3. Hot rolling can effectively improve the processing performance of metals and alloys, that is, break the coarse grains in the casting state, heal micro-cracks, reduce or eliminate casting defects, and transform the as-cast structure into an as-cast structure. Deform the structure and improve the processing performance of metal.

4. The cast structure is transformed into a processed structure through hot rolling, and the plasticity of the material is greatly improved through the transformation of the structure.

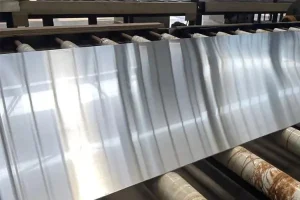

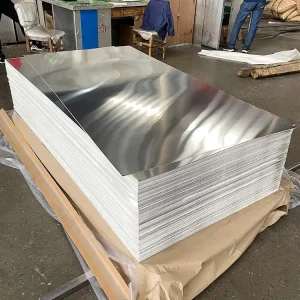

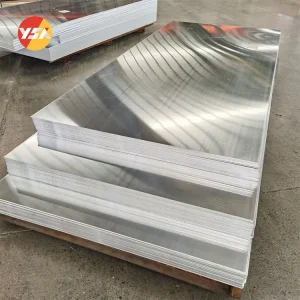

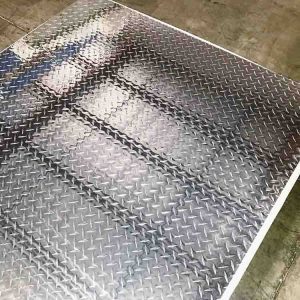

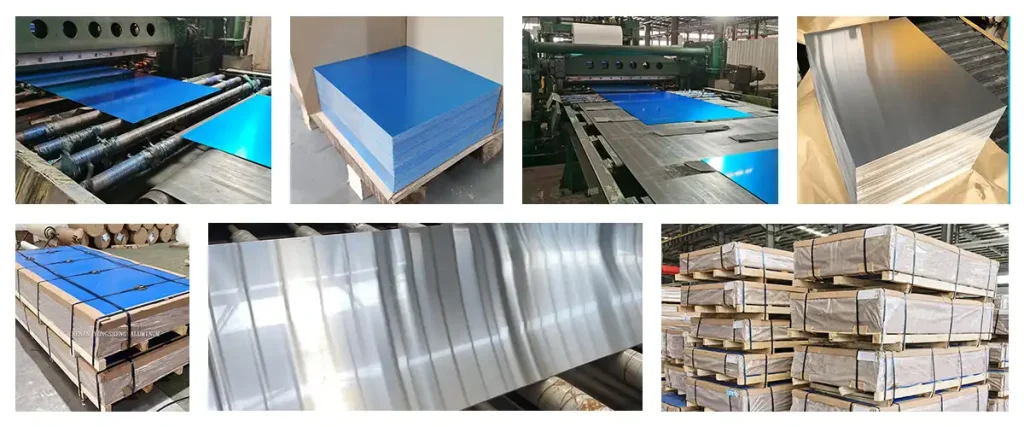

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes