Stucco Embossed Aluminum Coil

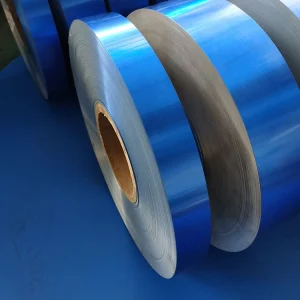

The stucco embossed aluminum coil undergoes a calendaring process that imparts intricate patterns on its surface. It is widely employed in industries such as packaging, construction, and curtain walls. Henan Yongsheng, a reputable manufacturer of stucco embossed aluminum coil, prides itself on its state-of-the-art facility that implements stringent quality controls throughout the aluminum foil production process. The company places a strong emphasis on sustainability and environmental responsibility, integrating eco-friendly practices at every stage of production.

Product Introduction

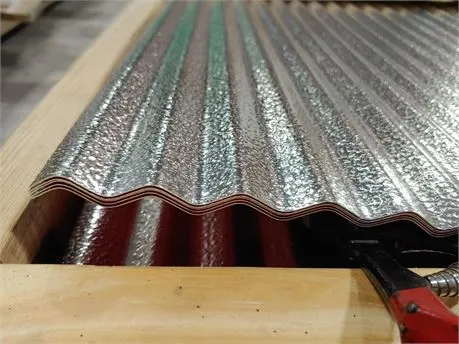

The stucco embossed aluminum coil exhibits a textured surface reminiscent of an orange peel. This texture is achieved by subjecting the natural mill finish material to embossing rollers. The resulting surface diffuses light, minimizing reflectivity and glare. The stucco embossed aluminum coil is utilized for decorative purposes and to reduce surface reflectivity. With aluminum renowned for its stability and durability, the stucco embossed coil serves exceptionally well as roofing or cladding material, eliminating the need for additional protective coatings.

Specifications

| Alloy | 1050,1060,1070,1100,3003,3105,5052 |

| Temper | 0,H12,H14,H16,H18,H22,H24,H26,H32 |

| Thickness(mm) | 0.25-2.00mm |

| Width(mm) | 1000-1500mm |

| Technology | hot rolled ( DC ), cold rolling ( CC ) |

| Surface Treatment | mill finish, bright finish, anodized, color coated |

| MOQ | 1 Tons |

| Delivery | Ready stock: 7-10 days, future goods: 15-30 days |

| Price term | EXW,FOB,CIF,CFR,CNF,etc. |

| Payment | L/C,T/T,Western Union,etc. |

| Certificates | ISO9001&GS&ROHS&FDA&TUV&ISO&GL&BV,etc. |

Product Applications

Stucco embossed aluminum coil is primarily used in applications such as cold storage, freezers, decorative panels for home appliances, corrugated roof sheets, anti-corrosion coatings for air-conditioning pipes, and patterned coils for machinery platforms and automotive skid coil industries.

Product Advantages

- The embossed aluminum sheet coil offers precise dimensions and is highly versatile in its applications.

- It demonstrates excellent plasticity, allowing for easy forming and processing.

- An oxide film naturally forms on the aluminum surface, providing effective corrosion resistance by preventing oxygen penetration.

- The embossed aluminum sheet coil exhibits good elongation and tensile strength, meeting standard processing requirements like stamping and stretching, and boasting high formability.

- The surface of the aluminum checker plate is of superior quality, free from oil marks, waves, scratches, roller marks, with neatly trimmed edges and no bur.

Product Process

The production of embossed aluminum coil begins with a flat aluminum coil, which is then passed through an embossing roller to create various concave and convex patterns on its surface. The surface can undergo additional treatments such as anodizing, color-coating, film-coating, or lamination with kraft paper, among other techniques.

- Melting and holding furnace

- Cold rolling

- Stretching and straightening

- Acid and alkali washing, followed by drying

- Embossing production

- Anodizing

- Cutting and packaging

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes