Aluminum disc lamp shades, as common lighting fixtures in the modern lighting industry, rely heavily on the precision and efficiency of their manufacturing process, directly impacting the quality and visual appeal of the final product. This article will introduce the production process and optimization techniques involved in crafting aluminum disc lamp shades.

Raw Material Preparation and Treatment

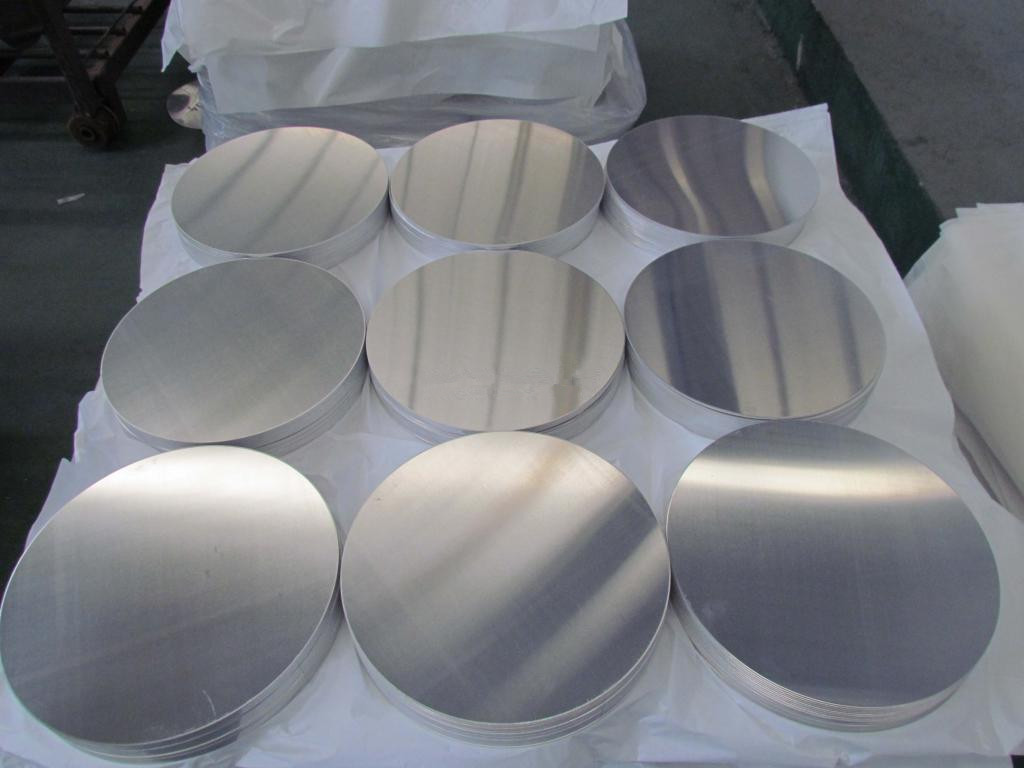

Aluminum alloy sheets are the primary raw material for manufacturing aluminum disc lamp shades. It’s essential to select suitable alloy types and sheet thicknesses. Before fabrication, the aluminum sheets undergo cleaning and surface treatment to ensure smoothness and cleanliness, minimizing the presence of any surface oxidation.

Aluminum Disc Cutting

Using shearing machines or laser cutting equipment, the aluminum sheets are precisely cut into circular discs of the required dimensions, according to the design specifications.

Stamping and Forming

The cut aluminum discs are then placed into stamping dies for forming. Careful control of the stamping speed and pressure is essential to ensure that the aluminum discs are shaped accurately according to the design requirements.

Surface Treatment and Decoration

Post-forming, the aluminum disc lamp shades undergo surface treatment processes such as deburring, polishing, and buffing to achieve a smooth and glossy surface finish. Depending on the design specifications, decorative processes such as spraying, oxidation, or silk screening may be applied to enhance the aesthetic appeal of the lamp shades.

Quality Inspection and Packaging

The finished products undergo rigorous quality inspection, covering aspects such as dimensions, surface quality, and overall appearance, to ensure compliance with design specifications and industry standards. Qualified products are then packaged using suitable packaging materials to protect them from damage during transportation.

Process Optimization and Innovation

To improve production efficiency and product quality, a series of process optimization and innovation measures can be implemented. This includes the adoption of advanced equipment and technologies, streamlining production processes, enhancing operational skills, and exploring innovative manufacturing techniques. These efforts aim to reduce costs, increase production capacity, and meet market demands effectively.

In the production process of aluminum disc lamp shades, process optimization is paramount. Through continuous improvement and innovation, manufacturers can enhance the competitiveness and market share of their products, driving industry development and advancement.