1050 aluminum sheets is a common industrial aluminum alloy material commonly used in various applications, including construction, automotive manufacturing, electronic products, furniture manufacturing, etc. Here are some basic information about 1050 aluminum sheets:

Chemical composition: The main alloying element of 1050 aluminum sheets is aluminum (Al), which usually contains over 99.5% aluminum, with very low content of other elements such as copper (Cu) and zinc (Zn).

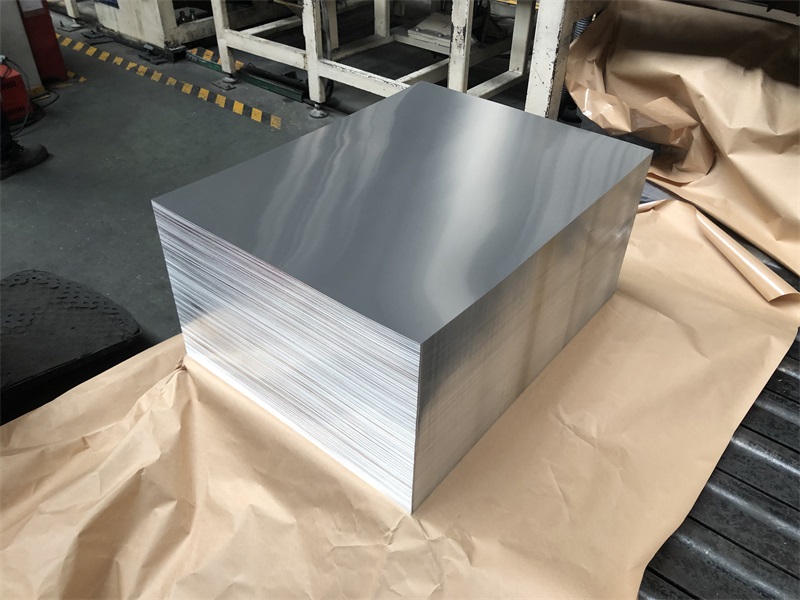

Features: 1050 aluminum sheets has good processing performance, is easy to cold and hot work, and can be processed into various shapes and sizes through processes such as rolling, stretching, and extrusion.

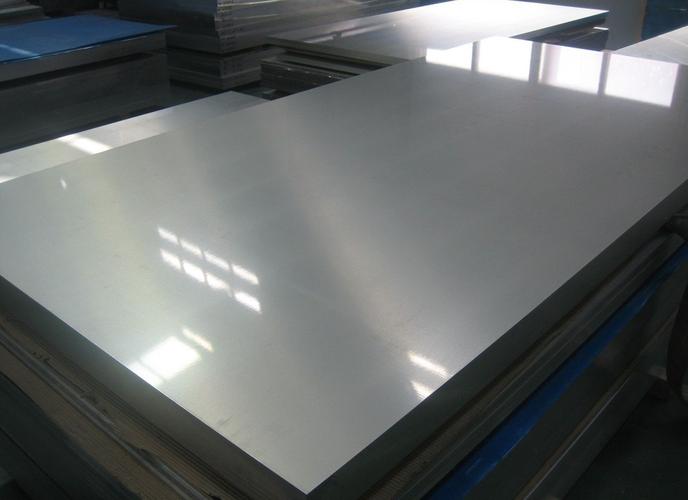

Surface characteristics: The surface of 1050 aluminum sheets is usually smooth and has excellent electrical and thermal conductivity properties.

Application areas: 1050 aluminum sheets are commonly used in applications that require high-purity aluminum materials, such as capacitor shells, kitchen utensils, aluminum discs, lighting accessories, etc.

Weldability: The 1050 aluminum sheets has good welding performance and can be connected to other metals or aluminum alloy materials through various welding processes.

Corrosion resistance: Due to its high purity, 1050 aluminum sheets has good corrosion resistance in general environments, but may be affected in high chlorine content or acidic environments.

Overall, 1050 aluminum sheets is a common high-purity aluminum alloy material with good processing performance and wide application fields, playing an important role in industrial production.