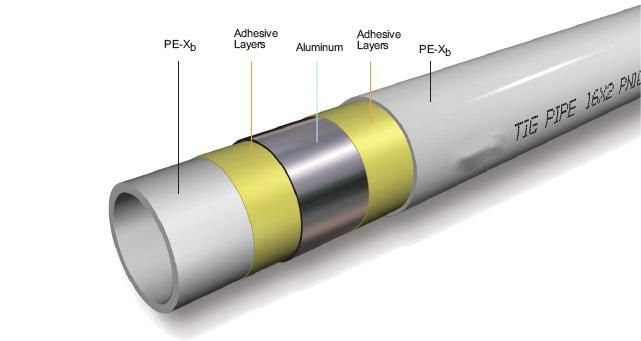

Composite pipes have become increasingly popular in modern industries due to their excellent performance and wide range of applications. One of the key materials used in the production of composite pipes is aluminum strips. These strips offer unique advantages and properties that significantly enhance the performance and longevity of composite pipes. Here are the detailed reasons why aluminum strips are chosen for composite pipes.

Excellent Corrosion Resistance

Aluminum strips possess outstanding corrosion resistance, ensuring that composite pipes maintain their stability and durability in various environmental conditions. The surface of aluminum forms a dense layer of aluminum oxide, which effectively prevents the intrusion of moisture, oxygen, and other corrosive substances, thereby extending the lifespan of composite pipes.

Lightweight and High Strength

Aluminum strips are characterized by their lightweight and high strength. This allows composite pipes to maintain high strength and load-bearing capacity while reducing the overall weight of the piping system. This characteristic not only lowers transportation and installation costs but also makes the pipes advantageous in applications where weight reduction is crucial.

Superior Thermal Conductivity

Aluminum strips offer excellent thermal conductivity, making them highly effective in heat transfer applications. Composite pipes made from aluminum strips are widely used in heating, ventilation, air conditioning (HVAC), underfloor heating, and hot water piping systems. Their superior thermal conductivity not only enhances system efficiency but also saves energy.

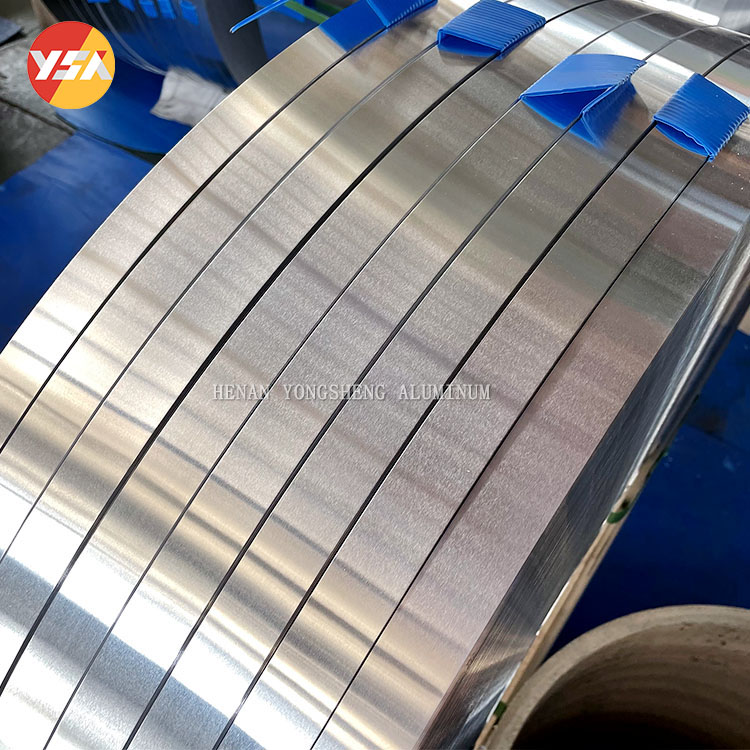

Good Machinability

Aluminum strips are easy to process, making them suitable for cutting, bending, welding, and other manufacturing operations. This allows for high precision and quality in the production of composite pipes. Additionally, the ductility and malleability of aluminum strips enable the pipes to adapt to complex shapes and design requirements, meeting various engineering needs.

Environmental Friendliness and Recyclability

Aluminum is an environmentally friendly material with a high recyclability rate. In the production and use of composite pipes, aluminum strips can be effectively recycled, reducing resource waste and environmental pollution. This characteristic aligns with modern society’s emphasis on sustainable development, making composite pipes a green and eco-friendly choice.

Cost-Effectiveness

Compared to other metallic materials, aluminum strips are relatively cost-effective and offer a high value-to-cost ratio. Using aluminum strips in composite pipes not only meets various application demands but also helps control costs, providing an economical and efficient solution. This makes composite pipes highly competitive in the market.

Conclusion

The choice of aluminum strips as the primary material for composite pipes is driven by their excellent corrosion resistance, lightweight and high strength, superior thermal conductivity, good machinability, environmental friendliness, and cost-effectiveness. These advantages ensure that composite pipes perform well in various environments and application scenarios, making them an ideal piping choice. As technology continues to advance and material science progresses, the application of aluminum strips in composite pipes is expected to become even more widespread and sophisticated.