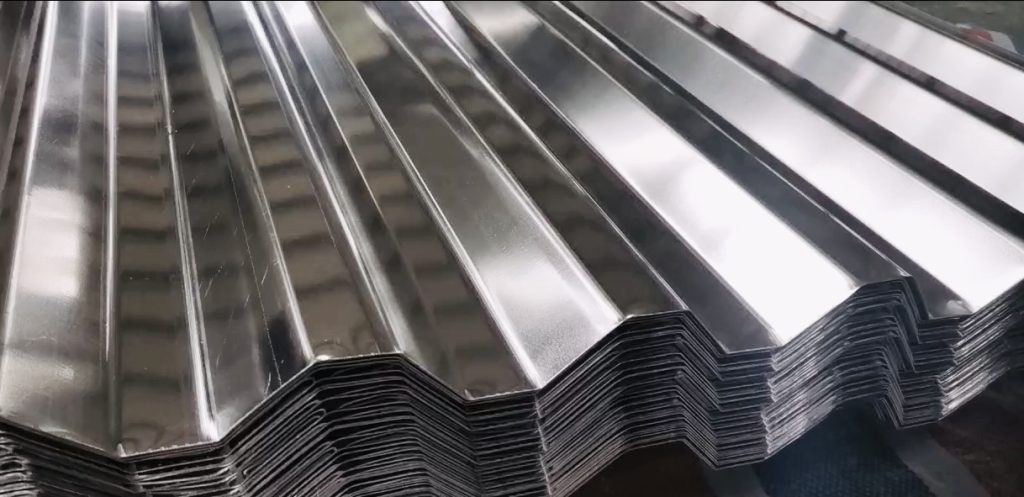

Corrugated aluminum sheet is a material with high labor costs, but it still has some important advantages:

Lightweight and high-strength

Corrugated aluminum sheets are lightweight, much lighter than traditional roofing materials such as concrete and ceramics, which can save roof truss costs and reduce the weight of buildings. At the same time, corrugated aluminum plates have high strength, strong hardness, and strong wind and seismic resistance.

Corrosion resistance and strong weather resistance

Corrugated aluminum plates have excellent corrosion and weather resistance, will not rust due to oxidation, and are not easily deformed or cracked.

Easy to process

As aluminum is a plastic material, corrugated aluminum sheets can be processed through processes such as cutting, trimming, bending, bending, stamping, and extrusion to meet the complex and diverse shapes and sizes required for different buildings.

Pinching strengthening

Aluminum is quite soft in nature, and the implementation of kneading strengthening technology during production of corrugated aluminum sheets can better improve their hardness.

Diversified colors

Corrugated aluminum sheets not only meet the needs of traditional colors, but also can be sprayed to achieve exquisite surface treatment, thereby presenting a perfect visual effect.

Low maintenance cost

Due to the excellent corrosion and weather resistance of aluminum, the maintenance cost of corrugated aluminum sheets is usually lower. Regular cleaning and inspection are necessary to maintain its good appearance and performance, and extend its service life.

In short, corrugated aluminum sheet is a building material with advantages such as high strength, light weight, speed, aesthetics, corrosion resistance, and easy processing. It has high social and economic value and broad prospects for promotion and application.