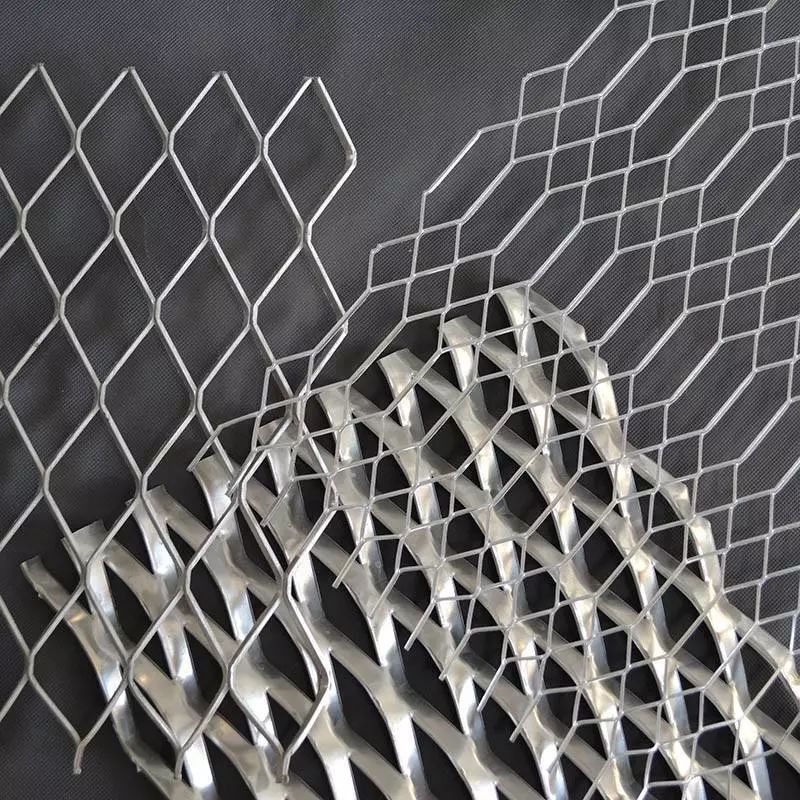

Aluminum mesh, with its versatile applications in various industries, often requires surface treatments to enhance both its durability and aesthetic appeal. Surface treatments not only protect aluminum mesh from corrosion and wear but also offer opportunities for customization and design. In this article, we will explore some common surface treatments for aluminum mesh and their benefits.

Anodizing

Anodizing is a popular surface treatment for aluminum mesh, involving an electrochemical process that forms a protective oxide layer on the surface. This oxide layer not only improves corrosion resistance but also enhances the mesh’s hardness and wear resistance. Anodized aluminum mesh is available in a variety of colors and finishes, offering greater design flexibility and aesthetic options.

Powder Coating

Powder coating involves applying a dry powder to the surface of the aluminum mesh and then curing it to form a durable and protective coating. This coating provides excellent resistance to corrosion, UV rays, and abrasion, making it ideal for outdoor applications. Powder-coated aluminum mesh is available in a wide range of colors and textures, allowing for customization to match specific design requirements.

Painting

Painting is another common surface treatment for aluminum mesh, offering versatility in color options and finishes. High-quality paint formulations provide excellent adhesion to the aluminum surface and offer protection against corrosion and weathering. Painting allows for precise color matching and customization, making it suitable for both functional and decorative applications.

Brushing or Polishing

Brushing or polishing is often used to enhance the aesthetic appearance of aluminum mesh, creating a brushed or polished finish. This process involves mechanically abrading the surface to create a uniform texture or a reflective surface. Brushed or polished aluminum mesh adds a sleek and modern look to architectural designs, making it a popular choice for interior and exterior applications.

Clear Coating

Clear coating involves applying a transparent protective layer to the surface of the aluminum mesh to preserve its natural appearance while providing protection against corrosion and oxidation. Clear-coated aluminum mesh retains its metallic luster and texture, making it suitable for applications where a metallic finish is desired without compromising durability.

In conclusion, surface treatments play a crucial role in enhancing the durability and aesthetics of aluminum mesh. Whether through anodizing, powder coating, painting, brushing, polishing, or clear coating, each surface treatment offers unique benefits and customization options to meet the specific requirements of various applications. By choosing the appropriate surface treatment, designers and manufacturers can achieve both functional performance and visual appeal in their aluminum mesh products.