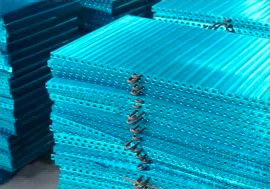

Aluminum strips are a crucial material in fin heat exchangers, widely used across various industries due to their excellent thermal conductivity, lightweight nature, corrosion resistance, and cost-effectiveness. Fin heat exchangers utilize the efficient heat conduction and dispersion properties of aluminum strips to achieve effective heat exchange. Below is a detailed exploration of the application of aluminum strips in fin heat exchangers and their benefits.

Working Principle of Aluminum Strip Fin Heat Exchangers

The working principle of fin heat exchangers revolves around increasing the surface area to enhance heat exchange efficiency. Aluminum strips are typically processed into thin, elongated fins that are tightly arranged around the core part of the heat exchanger, creating a large heat exchange surface. When a heat source (such as a condenser, evaporator, or electronic component) generates heat, it is conducted to the aluminum fins. Due to aluminum’s superior thermal conductivity, this heat quickly spreads across the fins and is subsequently dissipated into the surrounding air through convection and radiation, achieving efficient heat exchange.

Application Areas

Electronic Devices: In electronic devices, such as computers, servers, and communication equipment, aluminum strip fin heat exchangers are used to dissipate heat from processors and other high-temperature components. The aluminum fins quickly conduct and disperse heat, preventing the devices from overheating and ensuring their stable performance and long lifespan.

Automotive Industry: In the automotive industry, aluminum strip fin heat exchangers are widely used in engine cooling systems and air conditioning systems. By efficiently dissipating heat, aluminum fins help maintain the engine and air conditioning system within optimal temperature ranges, enhancing the overall performance and fuel efficiency of vehicles.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, aluminum strip fin heat exchangers are key components of condensers and evaporators. They facilitate efficient heat exchange to regulate indoor temperatures, ensuring the proper functioning and energy efficiency of the HVAC systems.

Industrial Equipment: Many industrial machines rely on aluminum strip fin heat exchangers for thermal management. For example, in welding machines, power transformers, and industrial furnaces, aluminum fins help dissipate heat, ensuring the equipment operates efficiently and safely.

Benefits

High Thermal Conductivity: Aluminum has excellent thermal conductivity, allowing it to quickly conduct and disperse heat. Aluminum fins significantly increase the heat exchange surface area, enhancing heat exchange efficiency.

Lightweight: Aluminum’s low density makes aluminum strip fin heat exchangers lightweight. This lightweight property is particularly important in applications where weight reduction is critical, such as in the aerospace and automotive industries.

Corrosion Resistance: Aluminum easily forms a dense oxide layer in the air, providing good corrosion resistance. This property ensures that aluminum strip fin heat exchangers maintain stable performance under various environmental conditions, extending their service life.

Cost-Effectiveness: Aluminum is relatively inexpensive and easy to process, making the manufacturing cost of aluminum strip fin heat exchangers relatively low. This cost-effectiveness makes them suitable for large-scale production and application.

Conclusion: Aluminum strips are widely used in fin heat exchangers, offering efficient thermal conductivity, lightweight, corrosion resistance, and cost-effectiveness. These properties make aluminum strip fin heat exchangers a reliable thermal management solution for electronic devices, the automotive industry, HVAC systems, and industrial equipment. As technology continues to advance, the design and manufacturing processes of aluminum strip fin heat exchangers will keep improving to meet the growing demand for efficient heat exchange, thereby enhancing the performance of various industry equipment.