Although cutting thin aluminum sheets can seem like a difficult operation, it is completely doable with the correct tools and methods. Whether you’re a professional tradesperson or a do-it-yourself enthusiast, learning how to cut thin aluminum sheets gives you a world of options for different tasks. Precise cutting is necessary for everything from creating complex designs to making necessary components. We’ll cover all you need to know in this guide to cut thin aluminum sheets expertly.

Comprehending Thin Aluminum Sheets

It’s important to know the material you’re working with before you start cutting. The thickness of thin aluminum sheets usually ranges from 0.016 inches to 0.249 inches. These sheets are perfect for a variety of applications, such as automotive, construction, and crafts, because they are lightweight, strong, and adaptable.

Safeguarding Measures

When using any kind of cutting equipment, safety should always come first. Make sure the proper safety equipment, such as gloves, safety goggles, and ear protection, is on before you start cutting thin aluminum sheets. To further prevent aluminum dust or fumes from entering your lungs, ensure sure your workspace has adequate ventilation.

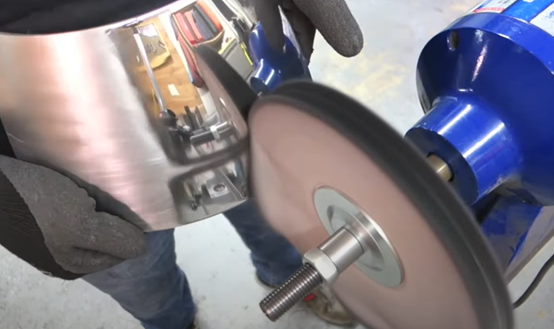

Implements and Machinery

Achieving precise and clean cuts requires selecting the appropriate equipment. Your best option for straight cuts is a circular saw with an aluminum carbide-tipped blade. An alternative tool for cutting curves and complex shapes is a jigsaw fitted with a metal-cutting blade. Precision cutting in confined locations is made easy with aviation snips.

Getting Ready to Cut

The secret to a successful cutting operation is planning. Using a straight edge and a marker, start by measuring and marking the metal sheet. To prevent waste, make sure your measurements are precise. To keep the aluminum sheet from sliding during cutting, firmly fasten it to your work surface next.

Methods for Cutting Very Thin Sheets of Aluminum

To achieve clean cuts, align your circular saw at the proper depth and follow your designated line with steady, even passes. To prevent the blade from overheating, be sure to move at a calm, steady speed. To ensure precision when cutting curved pieces with a jigsaw, take your time and pay great attention to the defined line. When cutting intricate shapes with aviation snips, begin with modest, deliberate motions and go cautiously through the material.

final-minute particulars

It is imperative to deburr the aluminum sheet’s edges after cutting in order to get rid of any jagged or sharp edges. To get a smooth and polished finish, use a file or a deburring tool. After deburring, use a fresh cloth to wipe the sheet clean of any remaining material.

Safety Protocols and Optimal Techniques

During the cutting operation, keep an eye out for potential power tool backlash, flying debris, and hot metal chips. When using cutting tools, always adhere to the manufacturer’s recommendations and instructions. If you lack the necessary skills or expertise, never try to cut aluminum sheets.

Conclusion

Learning how to cut thin aluminum sheets can lead to a plethora of creative opportunities for both professional and do-it-yourself projects. You may safely and accurately handle aluminum cutting chores with accuracy and efficiency if you adhere to the proper procedures and safety measures described in this book. For best outcomes, always put safety first and make sure your tools are properly maintained. For any craftsman, cutting thin aluminum sheets may be a lucrative and pleasant task if done correctly.