Although using aluminum foil as a battery fluid collector has many advantages, there are still a series of problems to deal with in the application process. Firstly, the certain rigidity of the aluminum foil causes the limited area in contact with the cathode material, thus affecting the internal resistance of the cathode sheet. Secondly, the bonding strength of the aluminum foil and the active substance is limited, and the electrode volume change causes the loose particles and easy powder loss, accelerating the rapid attenuation of the battery capacity and cycle life. Finally, the oxidation decomposition product of the electrolyte causes electrochemical reaction on the surface of the aluminum foil, promote the corrosion of the aluminum foil. To overcome these problems, the aluminum foil must be modified.

Surface carbon coating is the main modification method, which can significantly improve the internal resistance of aluminum foil. The main modification methods of aluminum foil include surface treatment (such as chemical etching, electrochemical etching, DC anodic oxidation, corona treatment), conductive coating (such as carbon coating, graphene coating, carbon nanotube coating, composite coating), 3D porous structure (such as foam structure, nanoband structure, nanocone mechanism, fiber weaving mechanism) and composite modification treatment. These methods play a key role in improving aluminum foil performance and enhancing the connectivity of electrode materials.

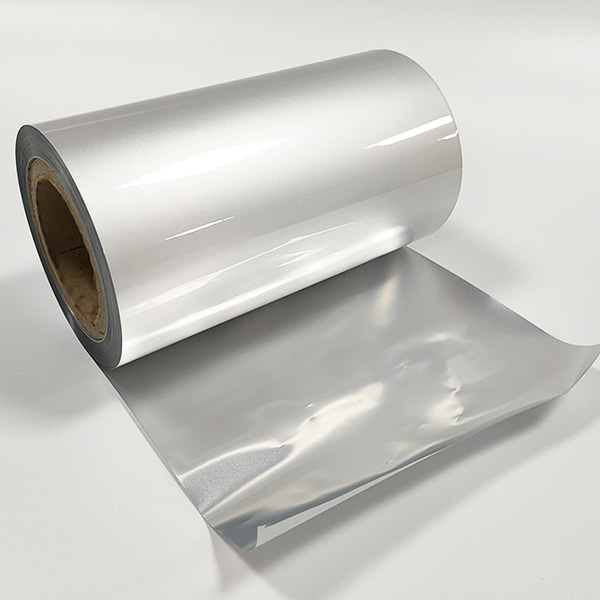

The new composite aluminum foil demonstrates excellent comprehensive performance in terms of battery safety, energy density and cycle life. Composite aluminum foil refers to the aluminum-coated composite film prepared by the evaporation process, with polyethylene terephthalate (PET) and other materials as the substrate. Its advantages include:

1)Improve safety: composite aluminum foil introduces organic insulation layer in the middle of the fluid collection, the layer can provide infinite resistance in the event of thermal runaway, and has the characteristics of non-combustion, so as to effectively reduce the risk of battery combustion fire and explosion, and significantly improve the safety of the battery;

2)Improve energy density: Because the PET material is light, the overall mass of PET aluminum foil is small (equivalent to replacing the middle part of the metal foil with a layer of PET), which reduces the weight of the battery and improves the energy density of the battery. According to the data of XinLi, when the overall thickness is basically not increased, the weight of composite aluminum foil is reduced by 50% -80% than the traditional calendering aluminum foil fluid collection, and the composite aluminum foil can be thinner, the final lithium battery volume is smaller, the energy density can be increased by 5% -10%;

3)Improve cycle life: According to gaogong lithium battery, composite aluminum foil uses polymer material to form a layered annular sponge structure, which can absorb the expansion-shrinkage stress caused by the embedding of the active material layer in the process of charge and discharge. This effectively maintains the long-term integrity of the polar sheet interface, allowing for a 5% increase in cycle life.

According to the technical requirements of aluminum foil, the development direction of aluminum foil in the future mainly focuses on reducing the thin thickness and increasing the strength. In recent years, with the rapid development of the lithium battery industry, the requirements for vehicle range are constantly expanding, and the demand for battery energy density is also gradually increasing. In this context, reducing the thickness and weight has become one of the key research and development directions for battery collection fluids. The thickness of the positive electrode aluminum foil has been reduced from 15-20 μ m several years ago to 8-10 μ m now.1070,1235,1100. In order to improve the energy density of the battery, the tensile strength and elongation should be enhanced while thinning the thickness of the aluminum foil.

Therefore, the main research and development directions in the future include the diversification of alloy and high-strength development. By conducting secondary processing on the basis of the aluminum foil of the original lithium battery, such as mechanical processing or DC etching method, the contact area of the fluid collector and the active material can be increased, so as to improve the capacity of the battery. This series of technological innovations is expected to boost the performance of battery aluminum foil to meet the growing demand for battery applications.