In the pharmaceutical industry, packaging plays a crucial role in ensuring the safety, stability, and effectiveness of medicines. Among the various packaging materials available, aluminum foil blister packaging has emerged as a cornerstone due to its exceptional protective properties and versatility. This article explores the development and significance of aluminum foil blister packaging in the pharmaceutical sector.

Introduction to Aluminum Foil Blister Packaging

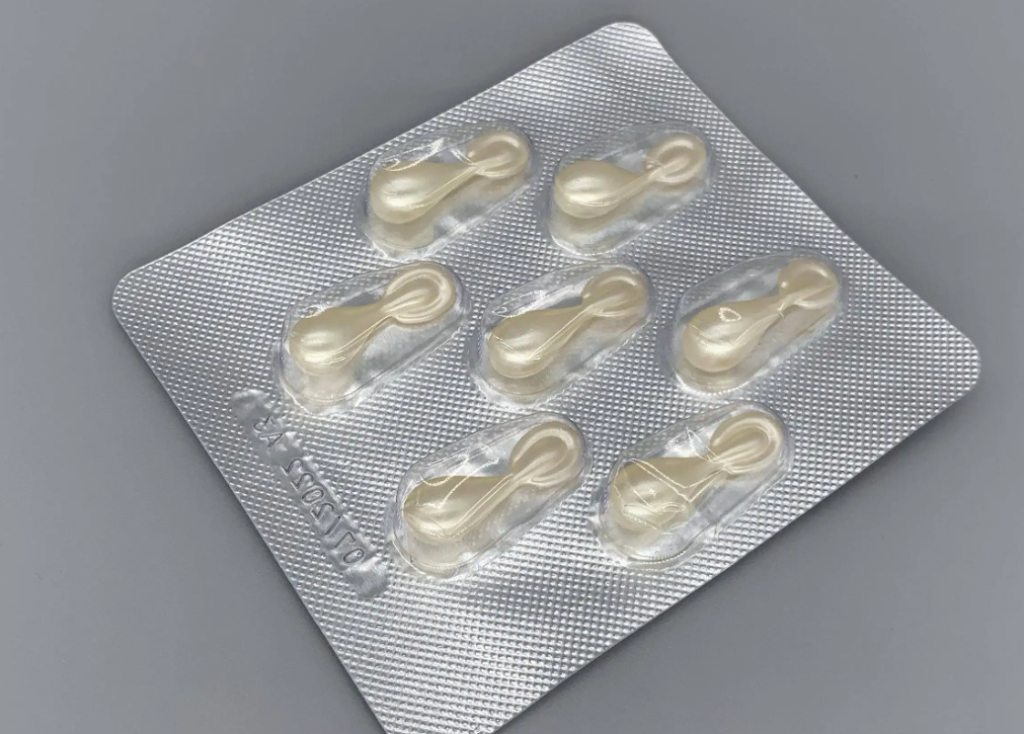

Aluminum foil blister packaging consists of a thin layer of aluminum foil and a heat-sealable polymer layer. This combination creates a robust and flexible packaging solution ideal for protecting pharmaceutical products. The aluminum foil provides a barrier against light, moisture, oxygen, and other environmental factors, while the heat-sealable polymer ensures secure sealing of the blister packs, preventing contamination and tampering.

Advantages of Aluminum Foil Blister Packaging

1.Enhanced Protection: Aluminum foil blister packaging offers superior protection to pharmaceutical products, shielding them from external factors such as light, moisture, oxygen, and microbial contamination. This helps maintain the integrity and stability of the medicines throughout their shelf life.

2. Extended Shelf Life: The barrier properties of aluminum foil significantly extend the shelf life of pharmaceutical products by preventing degradation and deterioration caused by exposure to external elements. This ensures that medicines remain safe and effective for longer durations.

3. Dosage Precision: Aluminum foil blister packaging allows for precise unit-dose packaging, facilitating accurate dispensing and administration of medications. Each blister cavity can contain a single dose of the drug, reducing the risk of dosage errors and ensuring patient safety.

4. Convenience and Compliance: Blister packs are convenient for patients to use, as they provide individually sealed doses that are easy to carry and administer. This promotes medication adherence and compliance, particularly for patients with complex dosage regimens.

5. Brand Integrity: High-quality aluminum foil blister packaging enhances the perceived quality and integrity of pharmaceutical brands. It serves as a reliable and trustworthy packaging solution, instilling confidence in consumers and healthcare professionals alike.

Future Trends and Innovations

Looking ahead, the development of aluminum foil blister packaging in the pharmaceutical industry is expected to continue evolving. Manufacturers are focusing on innovations to further enhance the performance, sustainability, and user-friendliness of blister pack designs. This includes the introduction of eco-friendly materials, advanced printing technologies for improved branding and patient information, as well as smart packaging solutions for enhanced safety and traceability.

In conclusion, aluminum foil blister packaging has become indispensable in the pharmaceutical industry, providing unparalleled protection, convenience, and brand integrity for medicines. As the industry progresses, ongoing advancements in blister pack technology will further optimize drug packaging and ensure the safe and effective delivery of medications to patients worldwide.