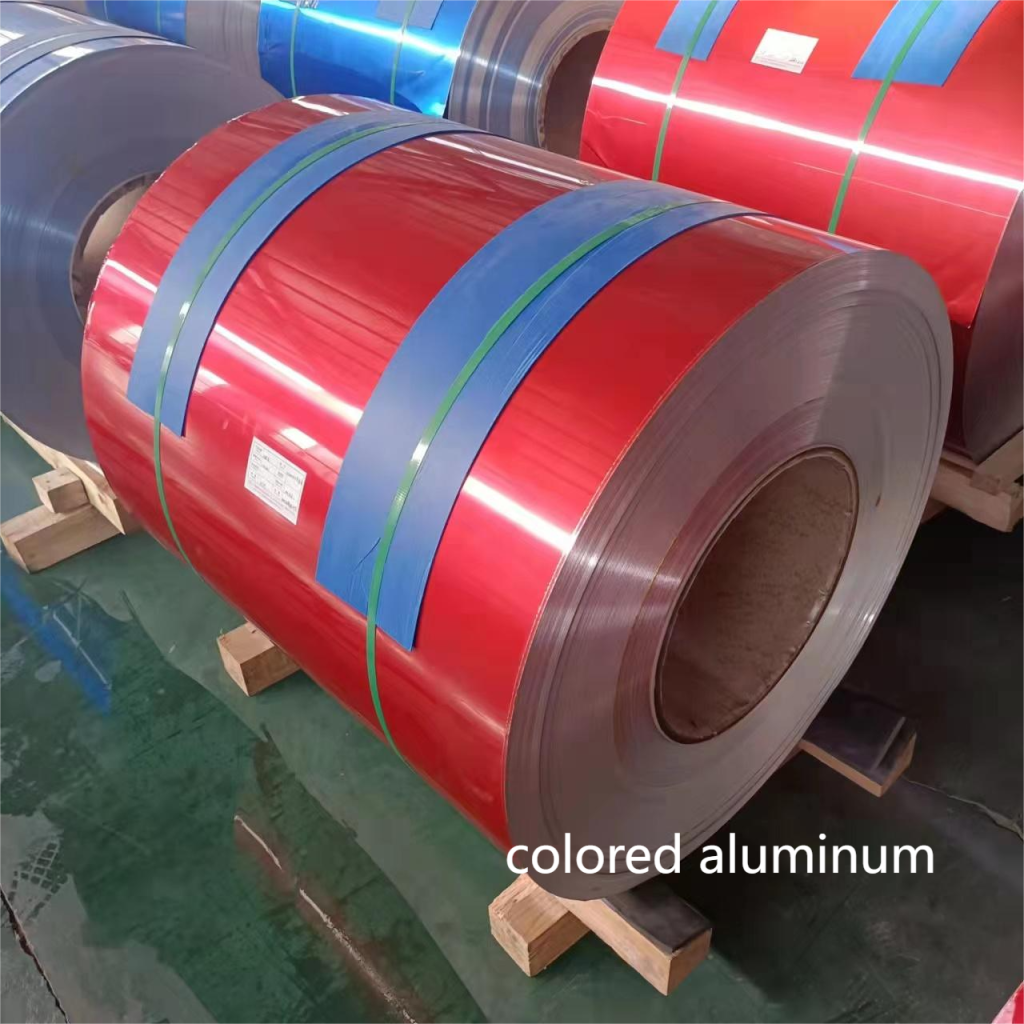

Ordinary colored aluminum and anodized aluminum are two commonly used surface treatment methods for aluminum plates, and their main differences are as follows:

1. Different processes: Ordinary colored aluminum is coated with a layer of color on the surface of the aluminum plate through a coating process, while anodized aluminum forms an oxide film on the surface of the aluminum plate through an electrochemical oxidation process.

2. Different color stability: Ordinary colored aluminum often has a brighter color, but due to its coating surface being easily scratched and worn, its color stability is relatively lower than that of anodized aluminum. The color of anodized aluminum oxide is relatively stable, and even slight wear or scratches will not affect its color.

3. Different physical properties: The oxide film of anodized aluminum forms a hardness similar to porcelain on the surface, with better physical properties such as wear resistance, heat resistance, and corrosion resistance, while ordinary colored aluminum is mainly limited to changes in surface color.

4. Different application ranges: Ordinary colored aluminum is suitable for indoor decoration, packaging and other fields due to its bright colors and convenient construction; Anodized aluminum oxide is more suitable for high-end construction, electronics, automotive, aerospace and other fields due to its stricter physical and chemical requirements.

In summary, the differences between ordinary colored aluminum and anodized aluminum include process, color stability, physical properties, and applicability. The choice of surface treatment method should be based on the specific usage environment, items, etc.