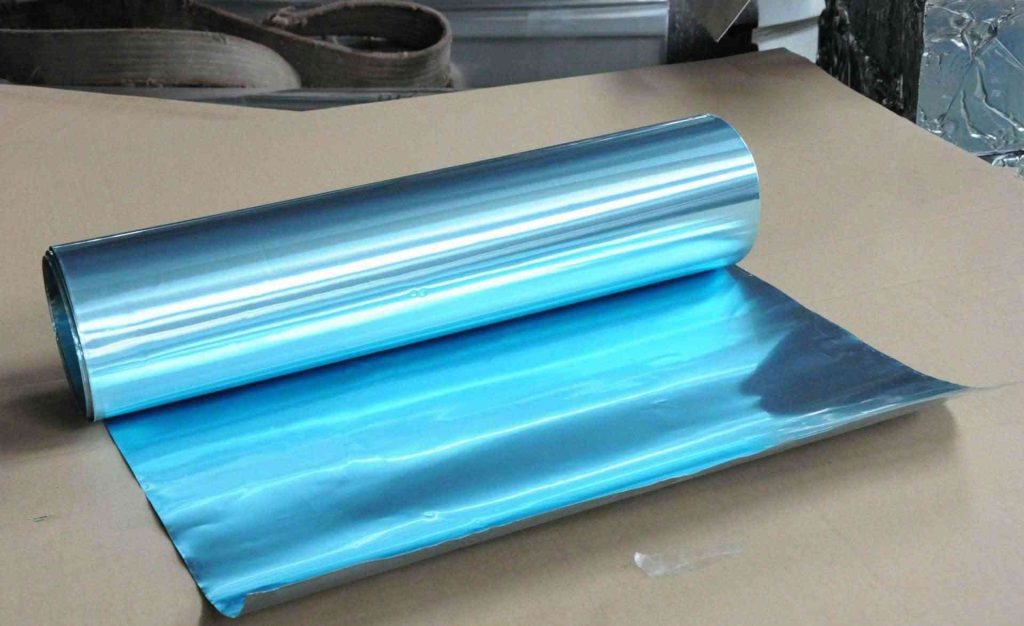

Aluminum foil plays a crucial role in the manufacturing of air conditioning equipment, boasting excellent heat insulation, conductivity, and corrosion resistance properties. It serves as a vital component in air conditioning systems, effectively enhancing their performance and efficiency. This article explores the characteristics, uses, and importance of aluminum foil in air conditioning systems.

Characteristics

Excellent Heat Insulation: Aluminum foil for air conditioning exhibits outstanding heat insulation properties, effectively blocking heat transfer and reducing energy loss.

Good Thermal Conductivity: Its excellent thermal conductivity allows for rapid heat transfer, aiding in heat dissipation and maintaining the equipment’s operational temperature.

Corrosion Resistance: Aluminum foil is highly resistant to corrosion, capable of withstanding moisture and chemical exposure, thus maintaining long-term stability.

Lightweight: Due to aluminum’s lightweight nature, aluminum foil contributes to reduced equipment load, enhancing transportation and installation convenience.

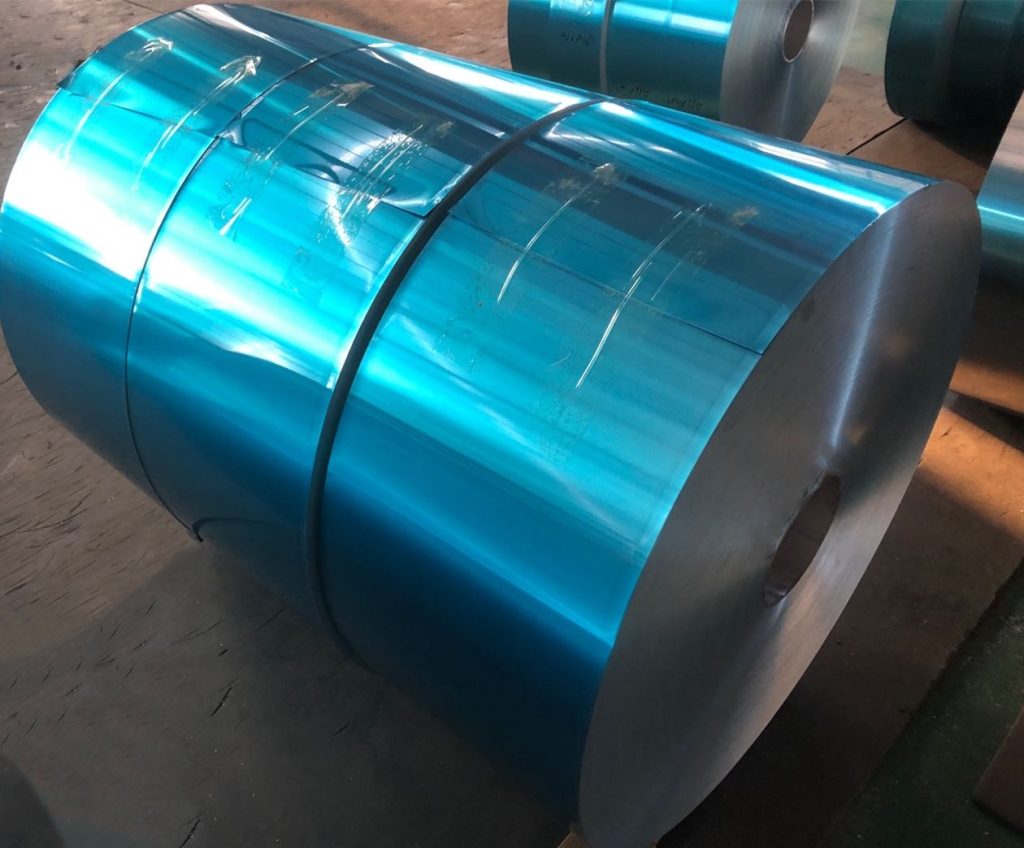

Uses

Heat Sink: Aluminum foil is commonly used as a material for air conditioning heat sinks. Its excellent thermal conductivity facilitates rapid heat dissipation, ensuring the air conditioning equipment operates at normal temperatures.

Insulation Layer: In air conditioning equipment, aluminum foil serves as an insulation layer, blocking external heat transfer, reducing energy loss, and improving the system’s energy efficiency.

Moisture Barrier: Due to its exceptional corrosion resistance, aluminum foil is often used to manufacture moisture barrier layers, protecting air conditioning equipment from moisture intrusion.

Connection Components: Aluminum foil is also used in the production of connection components, such as sealing materials for pipeline connections, ensuring the air conditioning system’s integrity and safety.

Importance in Air Conditioning Systems

Aluminum foil plays a crucial role in air conditioning systems, enhancing heat dissipation efficiency, energy efficiency, and equipment protection. Its use can significantly improve the system’s performance and longevity by safeguarding against corrosion and moisture intrusion. Therefore, selecting high-quality aluminum foil materials is essential in the design and manufacturing of air conditioning equipment to ensure optimal performance and stability.

Conclusion

Aluminum foil is a critical material in air conditioning equipment, offering excellent heat insulation, conductivity, and corrosion resistance properties. Widely used in heat sinks, insulation layers, moisture barriers, and connection components, its superior characteristics contribute to enhanced performance and energy efficiency in air conditioning systems. Therefore, it holds significant importance in the design and manufacturing process, ensuring air conditioning equipment operates efficiently and reliably.