Introduction

When it comes to purchasing aluminum sheets, the allure of low prices can be tempting. However, opting for the cheapest option may lead to a host of potential issues. This article explores why choosing cheap aluminum sheets can be problematic and underscores the importance of investing in high-quality materials.

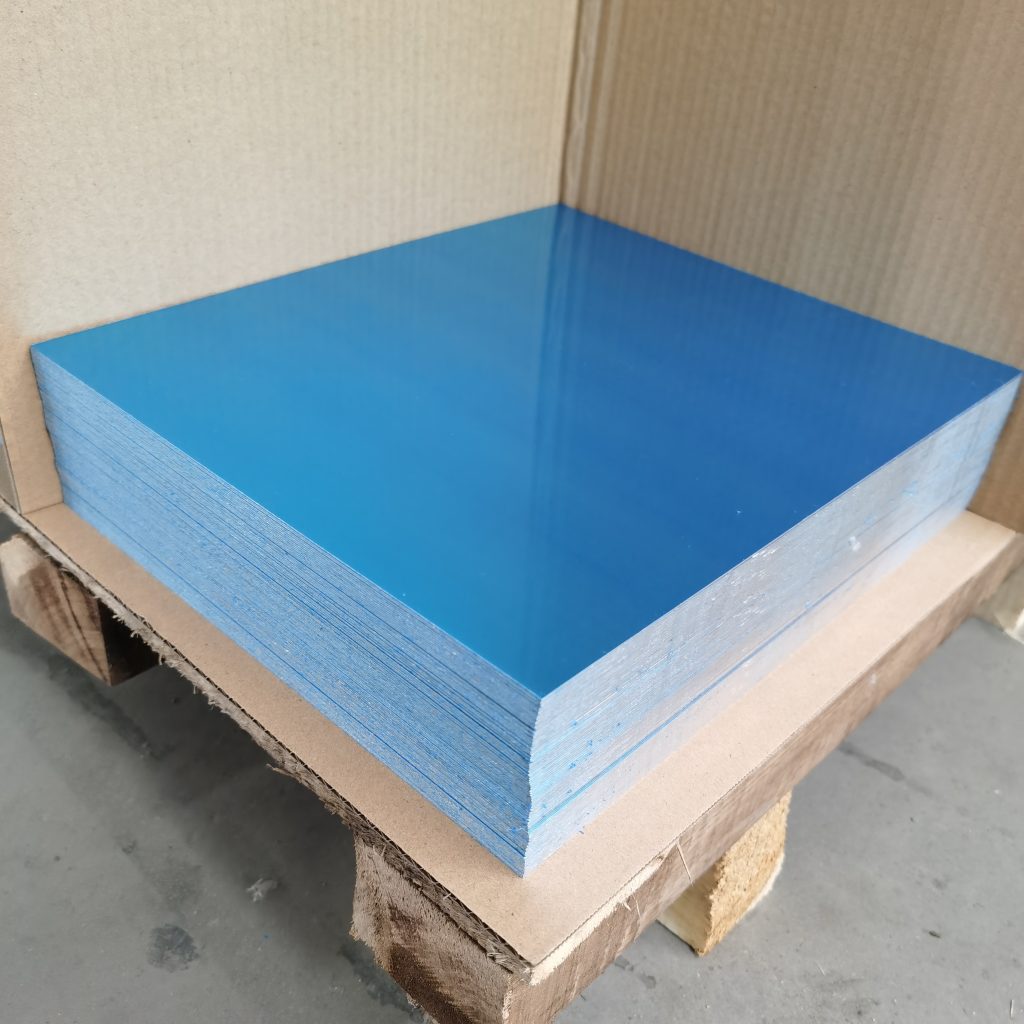

Quality of Materials

Cheap aluminum sheets often use inferior aluminum or contain impurities, leading to issues such as porosity, inclusions, and diminished mechanical properties. This compromises the reliability and durability of the product.

Lack of Precision in Manufacturing

Low-priced aluminum sheets may be manufactured using subpar processes, resulting in poor dimensional accuracy. This can cause difficulties during installation or usage, ultimately impacting the overall quality and performance of the product.

Surface Treatment Concerns

Some inexpensive aluminum sheets may forego proper surface treatments like anodizing, coating, or spraying. As a result, the surface may be rough and susceptible to corrosion, compromising aesthetics and longevity.

Failure to Meet Environmental Standards

Cheap aluminum sheets may be produced using materials or processes that do not adhere to environmental standards. This could pose risks to the environment and human health due to the presence of harmful substances.

Inadequate After-Sales Support

Low-priced aluminum sheets often come with limited or inadequate after-sales support. In the event of quality issues or changes in requirements, obtaining timely and effective assistance may prove challenging, leading to inconvenience and potential losses for the customer.

Conclusion

In conclusion, while the allure of cheap aluminum sheets may be tempting, it often comes at a cost. Opting for low-priced options can compromise quality, performance, and environmental compliance. Investing in high-quality aluminum sheets not only ensures product reliability and performance but also provides better after-sales support and environmental assurances.