Aluminum foil that has been laminated or bonded with other materials to improve its usefulness or qualities is referred to as composite aluminum foil. Depending on the application, this composite material may provide improved strength, flexibility, heat resistance, barrier qualities, or aesthetic appeal.

Common materials that are laminated with aluminum foil include:

Paper: Aluminum foil laminated with paper is often used in packaging applications where a combination of strength, barrier properties, and printability is required. It’s commonly seen in packaging for food products like butter, cheese, and chocolate.

Plastic films: Aluminum foil laminated with plastic films such as polyethylene (PE) or polypropylene (PP) provides enhanced barrier properties against moisture, oxygen, and light. This type of composite foil is used in flexible packaging for snacks, pharmaceuticals, and other perishable goods.

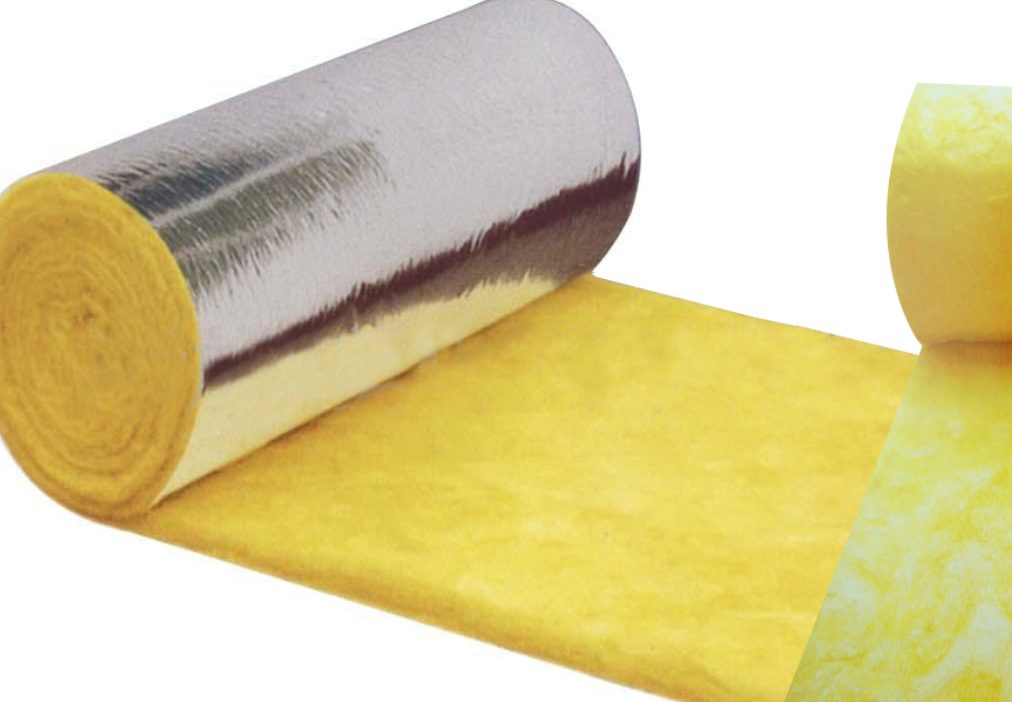

Fiberglass: Aluminum foil laminated with fiberglass is employed in insulation applications due to its heat resistance and reflective properties. It’s often used in construction for insulating walls, roofs, and HVAC systems.

Foam: Aluminum foil laminated with foam materials like polyethylene foam or expanded polystyrene (EPS) is used for thermal insulation in buildings, automotive applications, and packaging for fragile items.

Fabric: Aluminum foil can also be laminated with fabrics such as fiberglass cloth or non-woven textiles for applications requiring heat resistance and durability, such as protective clothing, thermal blankets, and insulation jackets.

Overall, composite aluminum foil offers versatility and can be tailored to meet specific requirements across various industries including packaging, construction, automotive, and aerospace.