Introduction

Aluminum strip slitting is a crucial step in the aluminum manufacturing process, involving the precise cutting of wide aluminum coils into narrower strips of specified widths. This article provides an indepth overview of the aluminum strip slitting process, highlighting its key steps and importance in aluminum production.

Coil Preparation

Before slitting, wide aluminum coils are received from suppliers. These coils are typically rolled aluminum sheets wound into large coils for easier handling and transportation.

Uncoiling

The aluminum coil is placed on an uncoiler, which gradually unwinds the coil in a controlled manner as the slitting process progresses.

Surface Preparation

The surface of the aluminum coil may be cleaned and straightened to ensure uniformity and smoothness before slitting.

Slitting

The aluminum coil passes through a set of slitting knives or blades, which cut it into narrower strips according to the desired width specifications. The slitting knives are adjustable to achieve precise widths, and tension control systems are used to maintain proper tension on the aluminum strip during the process.

Separation and Recoiling

After slitting, the narrower aluminum strips are separated from each other. The separated aluminum strips are then recoiled onto individual spools or coils, with each coil containing a specific number of strips as per customer requirements.

Quality Control

Throughout the slitting process, stringent quality control measures are implemented to ensure that the aluminum strips meet specified width tolerances and quality standards. Visual inspections and automated systems may be used to check for defects, ensuring the production of highquality strips.

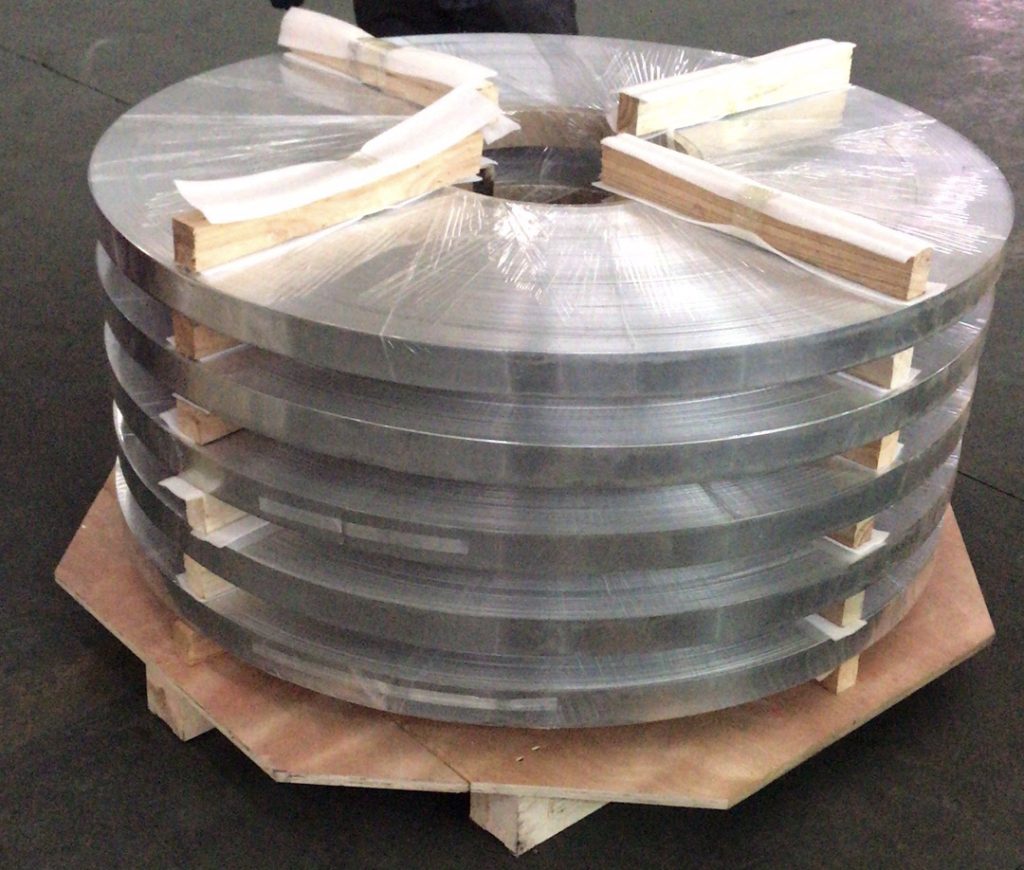

Packaging and Labeling

Once recoiled and inspected, the aluminum strip coils are packaged according to customer requirements. Packaging involves wrapping the coils in protective materials and labeling them with relevant information, such as dimensions, alloy type, and production batch numbers.

Storage and Shipment

The packaged aluminum strip coils are stored in a warehouse before shipment to customers. Coils are prepared for shipment, either by loading them onto trucks for local delivery or packaging them for transport via sea or air freight for international delivery.

Conclusion

The aluminum strip slitting process is a critical step in aluminum manufacturing, ensuring the production of highquality strips that meet customer specifications. By following precise procedures and implementing stringent quality control measures, manufacturers can produce aluminum strips suitable for a wide range of applications in industries such as automotive, construction, and electronics.