Finned aluminum foil, distinguished by its unique structure and exceptional heat dissipation properties, serves as a crucial component in various thermal management applications. Below, we delve into the comprehensive exploration of finned aluminum foil.

Structure and Shape

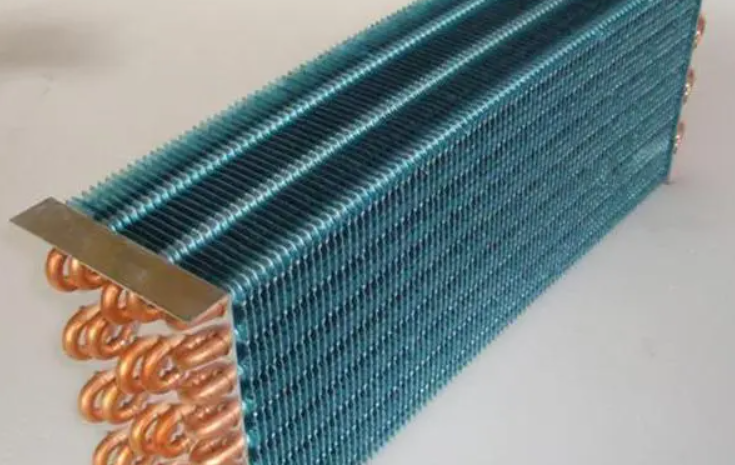

Finned aluminum foil is characterized by its surface adorned with numerous protruding fins, resembling the heat sinks commonly found in radiators or cooling fans. These fins are designed to increase surface area, thereby enhancing heat conduction efficiency and achieving more effective heat dissipation.

Material and Manufacturing

Finned aluminum foil is typically crafted from high-purity aluminum material, renowned for its excellent thermal conductivity and corrosion resistance. The manufacturing process often involves rolling, cutting, and forming aluminum foil, followed by specialized processing to create the finned structure, resulting in enhanced heat dissipation performance.

Thermal Management Applications

The primary application of finned aluminum foil lies in thermal management or heat conduction scenarios. For instance, they are frequently employed in electronic devices, automotive engines, air conditioning systems, LED lights, etc., serving as integral components of heat sinks or radiators. By installing finned aluminum foil around heat sources or in direct contact with them, it effectively improves heat dissipation efficiency, maintaining stable operating temperatures for equipment.

Thermal Conductivity

Benefiting from aluminum’s excellent thermal conductivity, finned aluminum foil rapidly conducts heat from the heat source to the surrounding environment, consequently lowering equipment temperatures and prolonging their service life. Moreover, the design of finned aluminum foil with an enlarged surface area further enhances its heat dissipation capabilities.

Environmental Friendliness and Recyclability

Aluminum is an environmentally friendly metal, and finned aluminum foil not only boasts superior heat dissipation performance but also exhibits excellent recyclability. After reaching the end of its service life, finned aluminum foil can be recycled and reused, minimizing resource wastage and aligning with the principles of sustainability.

In conclusion, finned aluminum foil, with its distinctive structure and remarkable heat dissipation capabilities, finds versatile applications across various industries. Its environmental friendliness and recyclability make it a crucial material in the realm of sustainable development.