Embossed Aluminum Coil Introduction

Embossed aluminum coil refers to a type of aluminum coil that has a textured pattern or design embossed or pressed onto its surface. The embossing process involves using a combination of heat and pressure to create raised or recessed patterns on the aluminum sheet or coil.

Embossed aluminum coils are commonly used in various industries and applications. The embossed patterns not only enhance the aesthetic appeal of the aluminum surface but also provide functional benefits such as improved grip, increased durability, and enhanced resistance to scratching or damage.

Common Embossed Patterns

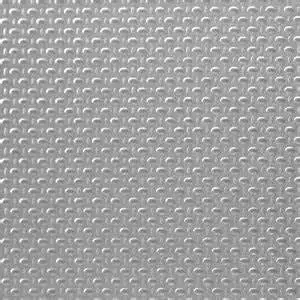

Stucco Pattern

The stucco pattern is perhaps the most widely used embossed pattern in aluminum coils. It features a raised texture that resembles the rough texture of stucco or plaster. The pattern consists of small, randomly arranged bumps or dots.

Characteristics: The stucco pattern provides excellent anti-slip properties and is commonly used in applications where grip is important, such as flooring, ramps, and staircases. It also helps to hide surface imperfections and provides enhanced strength and durability.

Diamond Pattern

The diamond pattern consists of a series of raised diamonds or lozenges embossed onto the surface of the aluminum coil. The diamonds are typically arranged in a regular, repeating pattern.

Characteristics: The diamond pattern offers excellent structural integrity and rigidity. It provides increased strength and resistance to bending or warping. The pattern is commonly used in applications that require a combination of strength and aesthetic appeal, such as truck beds, toolboxes, and decorative panels.

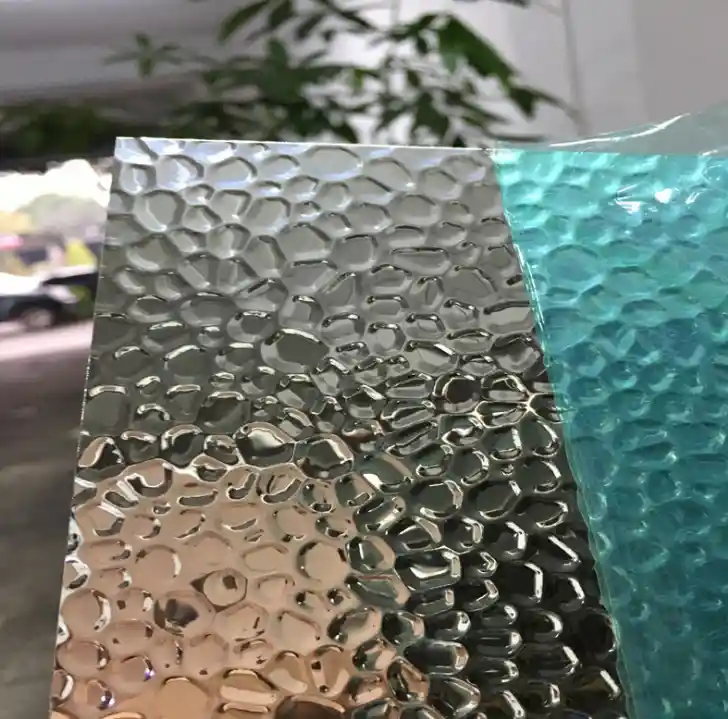

Hammer Pattern

The hammer pattern features a textured surface that resembles the hammered metal finish. It consists of irregular, raised indentations or dimples distributed across the surface of the aluminum coil.

Characteristics: The hammer pattern provides a unique and visually appealing texture. It offers good anti-slip properties and is commonly used in applications where both functionality and aesthetics are important, such as decorative elements, furniture, and interior design.

Orange Peel Pattern

The orange peel pattern gets its name from its resemblance to the texture of an orange peel. It consists of small, rounded bumps or dimples evenly distributed across the surface of the aluminum coil.

Characteristics: The orange peel pattern offers good anti-slip properties and provides a decorative and distinctive appearance. It is commonly used in applications such as refrigerator panels, air conditioning units, and decorative trim.

Linen Pattern

The linen pattern features a textured surface that resembles the weave of linen fabric. It consists of fine, parallel lines embossed onto the aluminum coil.

Characteristics: The linen pattern provides a sleek and sophisticated appearance. It is commonly used in architectural applications, interior design, and decorative elements where a refined and elegant texture is desired.

Embossed Aluminum Coil Processing

- Cleaning and Degreasing: Thoroughly clean and degrease the coil surface to remove contaminants that could impact the embossing process.

- Preheating: Preheat the aluminum coil to a specific temperature to make it more malleable for embossing.

- Embossing: Pass the preheated coil through embossing rollers or a press to apply pressure and heat, transferring the desired pattern onto the aluminum surface.

- Cooling and Quenching: Rapidly cool the embossed aluminum coil to set the pattern and stabilize the mechanical properties.

- Surface Treatment (Optional): Apply surface treatments such as anodizing, painting, or coating for enhanced corrosion resistance or improved aesthetics.

- Cutting and Slitting: Cut or slit the embossed aluminum coil into the desired widths or lengths to meet specific application requirements.

- Quality Inspection: Conduct a thorough inspection of the embossed aluminum coils to ensure they meet the required standards and specifications.

Embossed Aluminum Coil Application

Embossed aluminum coils find a variety of applications across different industries. Here are some specific applications where embossed aluminum coils are commonly used:

Construction Industry

- Roofing: Embossed aluminum coils are used for roofing sheets and panels, providing both aesthetic appeal and durability.

- Siding: They are used for exterior cladding of buildings, adding texture and visual interest.

- Decorative Elements: Embossed aluminum coils are utilized for decorative fascia, trim, and accents in architectural designs.

Transportation Industry

- Vehicle Panels: Embossed aluminum coils are used for manufacturing vehicle body panels, such as doors, fenders, hoods, and trunk lids.

- Trailers: They are used for trailer bodies, including cargo trailers, horse trailers, and recreational vehicle (RV) exteriors.

- Signage: Embossed aluminum coils are employed for producing signage, including traffic signs and advertising boards.

Packaging Industry

- Beverage Cans: Embossed aluminum coils form the basis for manufacturing beverage cans, providing texture and branding opportunities.

- Food Packaging: They are used for packaging applications in the food industry, such as trays, containers, and lids.

- Household Appliances

- Refrigerators: Embossed aluminum coils are utilized for the exterior panels of refrigerators, giving a textured and attractive finish.

- Ovens and Cooktops: They are used for panels and surfaces in kitchen appliances, providing durability and a stylish appearance.

Furniture and Interior Design

- Decorative Panels: Embossed aluminum coils find application in manufacturing decorative panels for furniture, wall coverings, and partitions.

- Trim and Accents: They are used for adding visual interest and texture to furniture pieces, cabinets, and fixtures.

- Industrial Applications

- Flooring and Steps: Embossed aluminum coils with anti-slip patterns, such as stucco or diamond, are used for industrial flooring, ramps, and steps.

- Toolboxes: They are used for manufacturing sturdy toolboxes with enhanced strength and resistance to damage.

Summary

In conclusion, embossed aluminum coil is a versatile and visually appealing material used in various industries. It is created by imparting raised or recessed patterns onto the surface of aluminum coils through an embossing process. The embossed patterns not only enhance the aesthetic appeal of the aluminum but also provide functional properties such as grip, anti-slip characteristics, and durability.

FAQ

What is the difference between aluminum sheet and coil?

The difference between aluminum sheet and coil is that an aluminum sheet is a flat, rectangular piece of aluminum, while an aluminum coil refers to a continuous roll of aluminum sheet that is produced by rolling it through a series of rollers.

What is aluminum coil sheet?

An aluminum coil sheet is a flat sheet that is cut from an aluminum coil, providing the convenience of a flat form while retaining the benefits of the continuous length from the coil.

What is the difference between engraving and embossing?

Engraving involves cutting or incising a design into a surface, creating a recessed pattern, while embossing involves creating raised patterns or designs on a surface by pressing or stamping it, resulting in a raised pattern or design that stands out from the surrounding surface.