Polyester laminated aluminum foil is a material made of polyester film and aluminum foil through a laminated process. It has many excellent properties and a wide range of applications. Polyester laminated aluminum foil is a laminated material made of polyester film as the base material, and aluminum foil and polyester film are laminated through adhesives or vacuum coating processes. This material has both the mechanical properties of polyester film and the high barrier properties of aluminum foil.

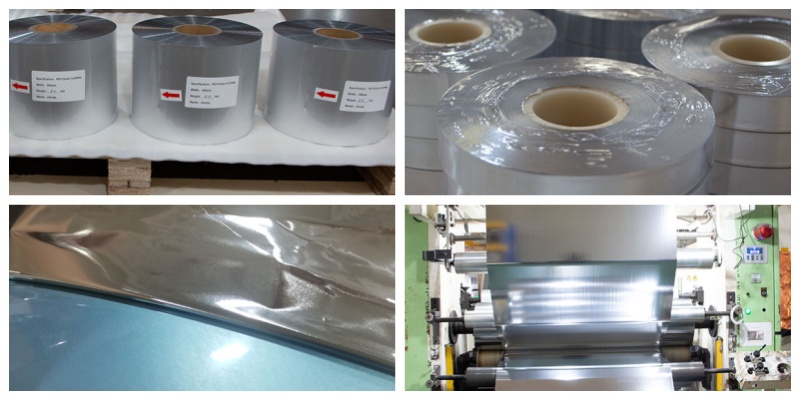

Polyester laminated aluminum foil production process

The production process of polyester laminated aluminum foil mainly includes three steps: aluminum foil production, laminated process, and post-processing

Aluminum foil production

- Aluminum ingot smelting: Aluminum ingots are melted into aluminum liquid.

- Casting and cold rolling: Through casting and multiple cold rolling processes, the aluminum liquid is processed into aluminum foil with a thickness of 0.05mm to 1.0mm.

- Annealing treatment: Intermediate annealing and finished product annealing are performed to improve the flexibility and ductility of the aluminum.

Combination process

- Vacuum evaporation: The aluminum foil is laminated with polyester film by vacuum evaporation. The advantages of vacuum evaporation include simple process and low cost, but high requirements for vacuum and cleanliness.

- One-time evaporation and secondary evaporation

- One-time evaporation method:1μm metal aluminum evaporation is completed in one time, which is suitable for large-scale production, but the interface bonding force may be insufficient.

- Secondary evaporation method:1μm metal aluminum evaporation is completed by reciprocating evaporation, which can improve interface stability and mechanical properties, but the process is complicated and the cost is high.

Post-processing

- Die-cutting: The laminated material is processed into the desired shape by a precision die-cutting machine.

- Cleaning and packaging: Ensure that the product surface is clean, dry, free of grease or other contaminants, and then package and store.

Polyester laminated aluminum foil structure

“Polyester laminated aluminum foil” is a laminated material, which is made of polyester film and aluminum foil tightly combined through a specific laminated process such as dry laminated, extrusion laminated, etc. It can be understood as a “sandwich” structure.

Surface layer/functional layer: polyester film

- Material: Polyethylene terephthalate.

- Main functions: 1.Excellent mechanical properties: Provide high strength, good tensile strength, tear resistance, puncture resistance and dimensional stability. 2.Good temperature resistance: Can withstand certain processing and use temperatures. 3.Excellent printability: Smooth surface, suitable for high-quality printing. 4.Good electrical insulation: It is an insulator itself. 5.Some barrier properties: It has a certain barrier effect on gas and water vapor, but not as good as aluminum foil. 6.Transparency : The original PET is transparent (but usually opaque after laminated).

Core barrier layer: aluminum foil

- Material: Extremely thin metal foil rolled from high-purity aluminum.

- Main functions: 1.Excellent barrier properties: This is its core value. Aluminum foil provides nearly perfect barrier properties, which can 100% block light, water vapor, oxygen, other gases and microorganisms. This can effectively protect the contents from light, oxidation, moisture, odor and corruption, greatly extending the shelf life. 2.Excellent electromagnetic shielding performance: It can effectively shield electromagnetic interference and radio frequency interference. 3.Good thermal conductivity: It is easy to heat seal, but usually needs to be used in conjunction with heat sealing materials. 4.Metallic luster: It provides a beautiful metallic texture.

Adhesive layer

- Function: Bond the polyester film and aluminum foil firmly together. This is usually achieved by coating an adhesive or co-extruding a layer of hot-melt adhesive resin.

- Requirements: The adhesive must have good bonding strength, temperature resistance, hygienic safety (meeting food and drug contact requirements) and stability.

The core advantage of polyester laminated aluminum foil is that it combines the advantages of two materials: the strength, toughness, printability and temperature resistance of PET + the extreme barrier and electromagnetic shielding of aluminum foil.

Polyester laminated aluminum foil laminated materials and their application scenarios

laminated materials

- Aluminum foil (AL): provides high barrier properties, opacity, high temperature resistance and oil resistance.

- Polyethylene (PE): has good heat sealing properties and is often used in the inner layer of laminated materials.

- Polypropylene (PP): has good chemical resistance and heat sealing properties.

- Nylon (PA): provides high puncture resistance and softness.

- Polyester film (PET): has high mechanical strength, high transparency and good printing properties.

- Paper: used for printing packaging and labels, with good printing effects and environmental protection.

Table 1: Characteristics and application scenarios of different laminated materials

| laminated material structure | Features | Application scenarios |

| PET/AL/PE | High barrier, high temperature resistance, oil resistance, good aroma retention, excellent heat sealing performance | Food packaging |

| PET/AL/CPP | High barrier, high temperature resistance | High temperature cooking food packaging |

| PET/AL/PA/PE | High barrier, puncture resistance, good softness | Vacuum bag, cooking bag |

| PET/AL/PP | High barrier, chemical resistance, good heat sealing performance | Food packaging, pharmaceutical packaging |

| PET/AL/paper | Good printing effect, high environmental protection, low cost | Printing packaging, label, hamburger aluminum foil |

| PET/AL/PE/PE | High barrier, high temperature resistance, oil resistance, good aroma retention | Food packaging, pharmaceutical packaging |

| PET/AL/PA/CPP | High barrier, puncture resistance, high temperature resistance | Heavy-duty packaging bags, cooking bags |

Factors affecting the price of polyester laminated aluminum foil

The price of polyester laminated aluminum foil is affected by many factors, including raw material cost, production process complexity, market demand and specifications. Generally speaking, the price of polyester laminated aluminum foil produced by secondary evaporation process is higher because of its complex process and better performance. In addition, the price of polyester laminated aluminum foil of different thickness and specifications will also be different

Due to its excellent performance and wide applicability, polyester laminated aluminum foil has become an important material in modern industry and packaging. The continuous optimization and diversification of its production process enables it to meet the needs of different industries, and also promotes the development of related industries