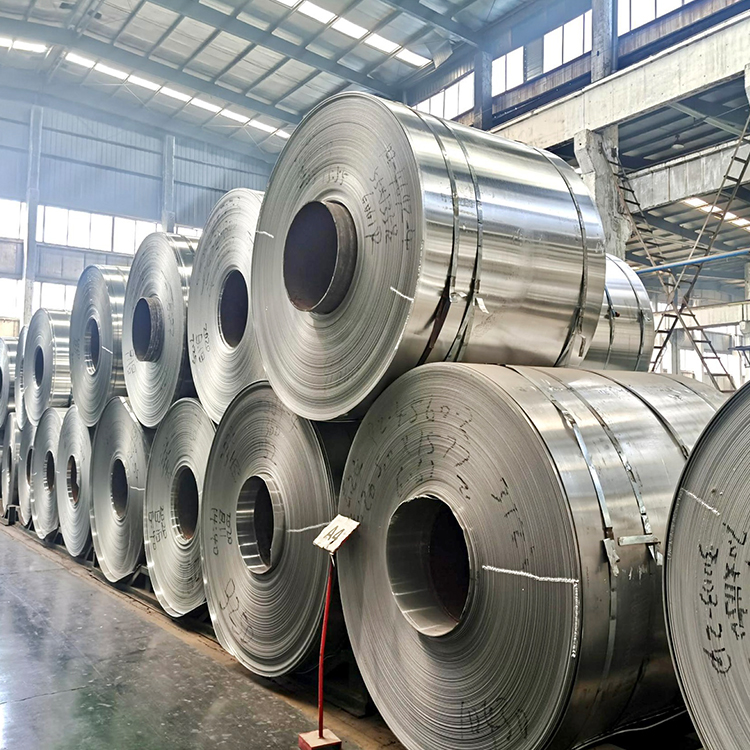

Introduction

In recent years, aluminum coils have been increasingly favored and utilized in various industries, gradually displacing traditional metal materials. This article delves into the reasons behind this trend and explores why aluminum coils are becoming the preferred choice over other metal materials.

Lightweight Advantage

One of the primary reasons for the growing preference for aluminum coils is their lightweight nature. Aluminum is significantly lighter than other metals such as steel and copper, making it ideal for applications where weight reduction is crucial, such as automotive, aerospace, and transportation industries. The use of aluminum coils helps to enhance fuel efficiency, increase payload capacity, and improve overall performance.

Excellent Corrosion Resistance

Aluminum coils exhibit excellent corrosion resistance, particularly when exposed to moisture and harsh environmental conditions. Unlike steel, which can rust and deteriorate over time, aluminum forms a protective oxide layer on its surface, preventing corrosion and ensuring long-term durability. This makes aluminum coils particularly suitable for outdoor applications, including building facades, roofing, and marine structures.

High Strength-to-Weight Ratio

Despite its lightweight nature, aluminum boasts a high strength-to-weight ratio, offering impressive strength characteristics. This enables the fabrication of lightweight yet structurally robust components and structures, reducing material usage without compromising performance. As a result, aluminum coils are increasingly used in structural applications where strength and durability are paramount.

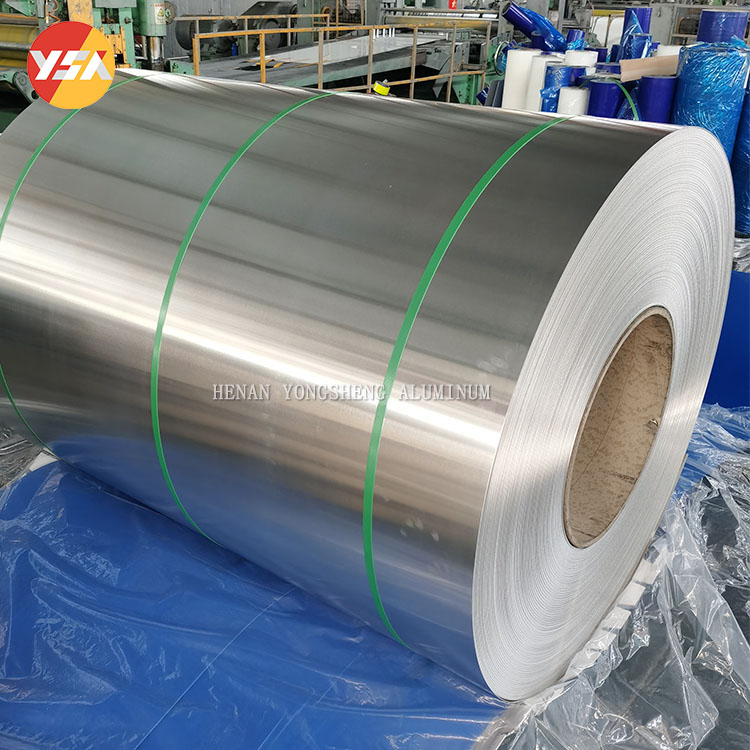

Versatility and Formability

Aluminum is highly versatile and can be easily formed into various shapes and sizes through processes such as rolling, extrusion, and stamping. This versatility allows for the creation of complex and intricate designs, making aluminum coils suitable for a wide range of applications across different industries. Additionally, aluminum’s ability to be easily recycled further enhances its appeal as an environmentally friendly material choice.

Cost-Effectiveness

Advancements in aluminum production technologies have led to reduced manufacturing costs, making aluminum coils more economically viable compared to other metals. Additionally, aluminum’s lightweight nature translates to lower transportation costs and easier handling during fabrication and installation, further contributing to its cost-effectiveness.

Sustainability and Environmental Benefits

Aluminum is a highly sustainable material with a low carbon footprint. It is widely recycled with minimal loss of properties, making it an environmentally friendly choice compared to other metals. The increasing focus on sustainability and environmental conservation has led to a growing preference for aluminum coils in various industries seeking to minimize their environmental impact.

Conclusion

The gradual replacement of other metal materials by aluminum coils can be attributed to a combination of factors, including lightweight advantage, excellent corrosion resistance, high strength-to-weight ratio, versatility, cost-effectiveness, and environmental benefits. As industries continue to prioritize performance, efficiency, and sustainability, aluminum coils are expected to play an increasingly dominant role in the manufacturing and construction sectors.