Beverage cans are ubiquitous in our daily lives and are widely favored for their lightweight, easy-to-open, and recyclable properties. Aluminum trim coil, the core raw material for cans, has become the preferred choice in the food packaging industry due to its excellent performance. But why does aluminum coil stand out among so many other materials? This article explores the application of aluminum coil in can manufacturing and analyzes its advantages and market prospects.

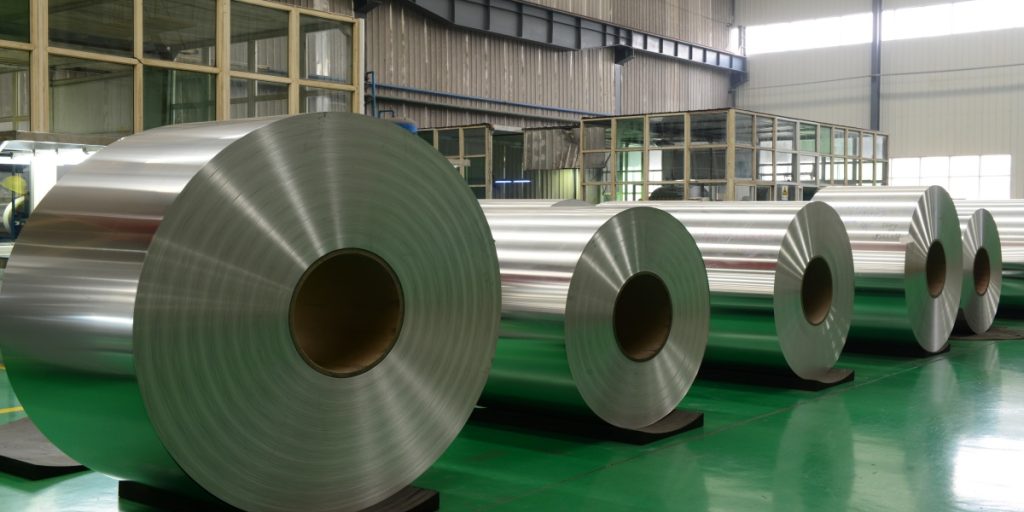

What is aluminum coil

Aluminum coil is a continuous coil of aluminum or aluminum alloys processed through a rolling process. This lightweight, silvery-white material retains the inherent properties of aluminum while enabling customizable performance through alloying and process optimization, making it an indispensable foundational material for modern industry. According to international standards, aluminum coil can be classified into three primary tempering states: annealed, work-hardened, and heat-treated. Each state offers unique mechanical properties, meeting the diverse needs of different applications.

Why is Aluminum Coil the Preferred Choice for Beverage Cans

When we pick up an ice-cold beverage can, few of us notice the material science behind its lightweight design. Think about it—a standard aluminum can weighs about as much as three Chinese 1-yuan coins, thanks to aluminum being just one-third the density of steel. This lightweight magic doesn’t just make drinks easier to carry—it transforms logistics. Every truck can haul 20% more aluminum cans, slashing both shipping costs and carbon emissions. In addition to this feature, aluminum coils also have the following characteristics.

Excellent Corrosion Resistance

Aluminum naturally forms a protective oxide layer, preventing beverage corrosion, ensuring food safety, and extending shelf life.

Superior Formability & Machinability

Aluminum coil is highly ductile, allowing efficient deep drawing and stamping into can bodies, lids, and other components.

100% Recyclable, Eco-Friendly & Energy-Efficient

Aluminum has a recycling rate of over 95%, and producing recycled aluminum uses only 5% of the energy required for primary aluminum, aligning with global sustainability trends.

How is Aluminum Coil Transformed into Beverage Cans

The processing of aluminum coils into beverage cans is a highly automated manufacturing process that integrates material science, machining and surface treatment technologies. Each step requires strict control of various process parameters.

Table: 1

| Stretching and thinning | 0.1-0.15mm |

| Mold clearance | 8-10%Material thickness |

| Stretching speed | 15-20m/min |

| Lubricant pH | 8.5-9.5 |

| Food grade epoxy resin coating on the inner wall | 5-8μm |

| Baking temperature | 200℃ |

| Sealing thickness | 1.25-1.45mm |

Market Outlook for Aluminum Beverage Cans

With growing environmental awareness and beverage industry expansion, aluminum can demand continues to rise:

- Beverage Industry: Carbonated drinks, beer, and energy drinks widely use aluminum cans.

- Eco-Policy Drivers: Global plastic bans push brands toward recyclable aluminum packaging.

- Tech Innovations: Ultra-thin can technology (e.g., 10% lighter “lightweight cans”) reduces costs further.

Aluminum coil is the ideal material for beverage cans due to its lightweight, corrosion-resistant, and fully recyclable properties. As sustainable packaging trends grow, aluminum cans will capture even more market share. Future advancements in thinner, more energy-efficient aluminum coil technology will further drive industry innovation, balancing eco-friendliness and cost efficiency.