Introduction

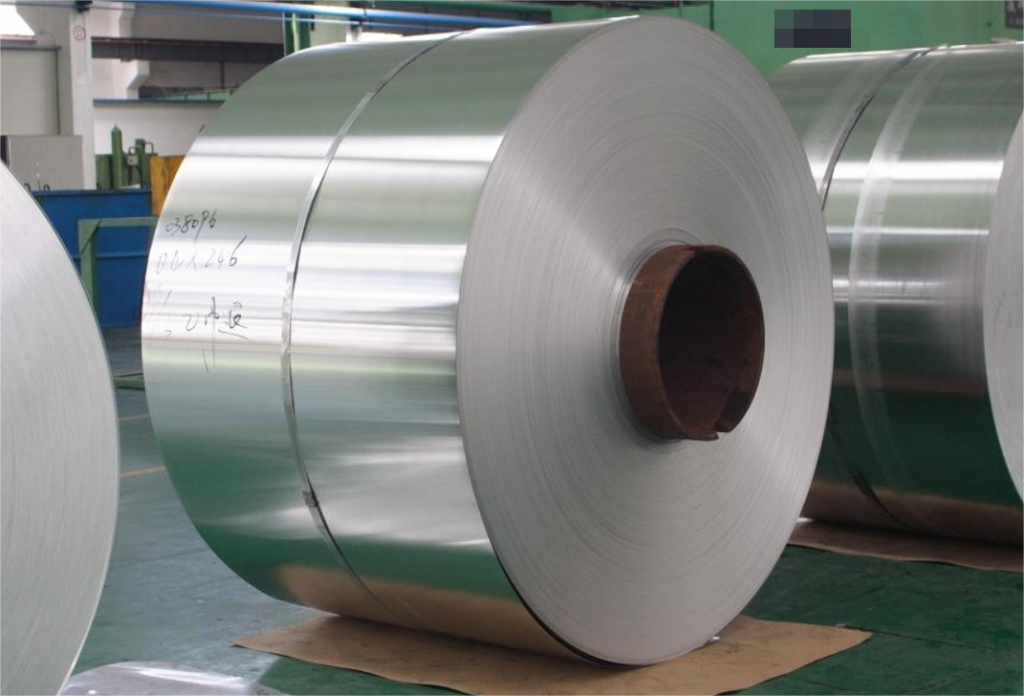

In aluminum foil production, the preference for using 8xxx series aluminum alloy as raw material is a common practice. This choice is not only attributed to the excellent characteristics of 8xxx series aluminum alloy but also to the superior performance and effects it provides during the aluminum foil manufacturing process. This article explores the reasons behind the frequent selection of 8xxx series aluminum alloy for aluminum foil production.

Strength Advantage

The 8xxx series aluminum alloy possesses outstanding strength characteristics, especially performing well under high-temperature conditions. This high strength ensures stability during aluminum foil production, enabling it to withstand significant tensile and compressive forces, thereby enhancing production efficiency and product quality.

Good Workability

8xxx series aluminum alloy exhibits excellent workability, making it easy to undergo processes such as rolling, stretching, and pressing. This workability streamlines the aluminum foil production process, facilitating the achievement of desired thicknesses and dimensions.

Corrosion Resistance

The 8xxx series aluminum alloy demonstrates excellent corrosion resistance against water, oxygen, and various chemicals. This resistance ensures that aluminum foil is less susceptible to corrosion and oxidation during use, maintaining its appearance and performance over time.

Excellent Thermal Conductivity

8xxx series aluminum alloy has good thermal conductivity, allowing for the rapid transfer of heat. In aluminum foil production, this excellent thermal conductivity contributes to the quick and uniform cooling and solidification of aluminum foil, enhancing production efficiency and ensuring product quality.

Lightweight Design

The 8xxx series aluminum alloy has a lower density, offering excellent potential for lightweight design. In aluminum foil production, using 8xxx series aluminum alloy can reduce the weight of the product, improve material utilization, and align with the current trend of lightweight and energy-efficient designs.

Conclusion

In summary, the 8xxx series aluminum alloy is widely selected and applied in aluminum foil production due to its outstanding strength, workability, corrosion resistance, thermal conductivity, and lightweight design characteristics. Choosing 8xxx series aluminum alloy as the raw material for aluminum foil production not only ensures product quality and production efficiency but also meets market demands and environmental requirements, promoting the sustainable development of the aluminum foil industry.