In the world of chocolate, where sensory experiences are paramount, safeguarding quality begins with the first barrier: packaging. A piece of premium chocolate embodies the essence of cocoa beans and the meticulous work of artisans. The key to ensuring this rich flavor reaches consumers perfectly lies in the chocolate bar foil packaging.

Chocolate is a delicate and sensitive food, vulnerable to light, oxygen, moisture, temperature fluctuations, and odors. As a leading aluminum foil manufacturer in China, we understand the demanding demands of the chocolate industry and provide packaging solutions that lay the foundation for quality for chocolate manufacturers worldwide.

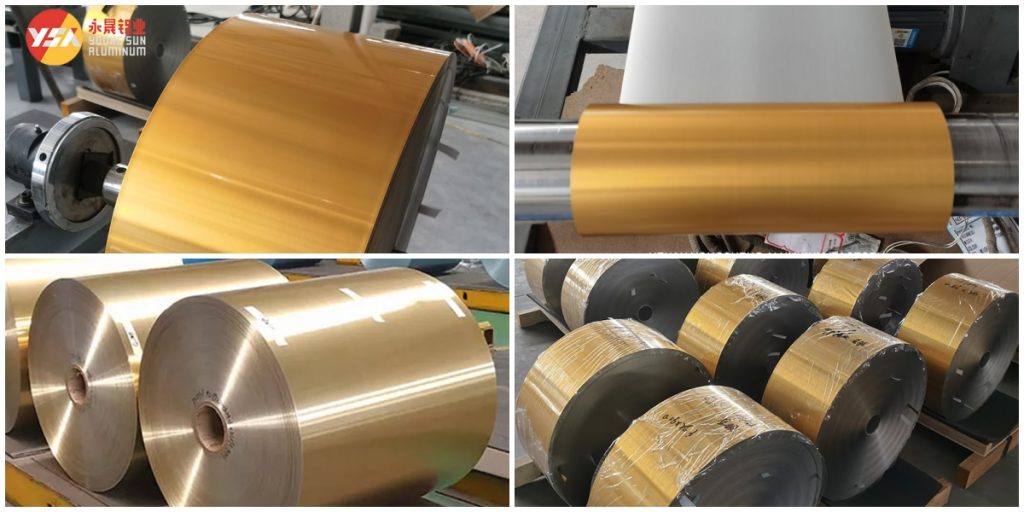

YSA Golden Chocolate Bar Foil Preservation Performance

Oxygen Transmission Rate

High-quality aluminum foil has an OTR of nearly 0 cm³/(m²·day·atm). This means it virtually completely blocks oxygen penetration, effectively preventing fat oxidation and rancidity, and preserving the fresh taste of chocolate. Experiments have shown that chocolate packaged in high-quality aluminum foil can significantly extend its flavor stability by over 30%-50% under the same storage conditions. The water vapor transmission rate (WVTR) is also close to 0 g/(m²·day). This dense barrier completely blocks moisture from entering the chocolate, preventing it from becoming soft and sticky due to moisture absorption, and preventing “blooming” caused by sugar leaching, maintaining its smooth texture and flawless appearance.

Light Blocking Rate

Aluminum foil offers over 99% light blocking capability. Light is the primary culprit for photooxidation of chocolate lipids, flavor degradation, and surface discoloration. Golden aluminum foil protects the rich color and pure flavor of chocolate.

An Indestructible Moisture Shield

Chocolate is extremely sensitive to humidity. A relative humidity exceeding 50% can cause quality issues. Yongsheng’s golden aluminum foil, thanks to its metallic nature and precision rolling process, forms a continuous, pinhole-free barrier, ensuring an absolutely dry microenvironment for chocolate even in high humidity environments of 85%+.

Comprehensive Environmental Protection

- Temperature Buffer: Aluminum foil offers excellent thermal conductivity, helping to quickly disperse localized heat, reducing thermal shock caused by temperature fluctuations and preventing surface oiling and deformation of the chocolate.

- Odor Isolation: Effectively blocks the intrusion of external odors, ensuring the pure aroma of the chocolate remains uncontaminated.

YSA Chocolate Bar Foil: Lightweight and Flexible

Modern aluminum foil maintains excellent mechanical strength and toughness even at extremely thin thicknesses, such as 0.006mm to 0.02mm. This is achieved by selecting the right grade and temper, such as H18, which offers high strength. This makes packaging.

- Extremely Lightweight: Significantly reducing packaging material and transportation costs, aligning with sustainable development trends.

- Perfectly Shapeable: Tightly and conformably wraps various complex shapes and sizes, such as shaped chocolate bars, truffles, and chocolate bars, ensuring the product maintains its perfect form during transportation and on-shelf display, avoiding breakage or wear.

- Automation-Friendly: Its excellent ductility and tensile strength make it suitable for the demanding requirements of high-speed automated packaging lines, improving production efficiency.

Why Choose YSA Aluminum Foil?

As a B2B company deeply engaged in aluminum foil manufacturing, Yongsheng Aluminum specializes in providing high-quality raw aluminum foil for the global chocolate packaging industry. We understand that we are the core upstream of the industry chain and the trusted force behind many renowned packaging companies.

Focus on Core Strengths

We specialize in producing premium aluminum foil rolls for chocolate packaging. We do not engage in subsequent processing steps such as printing, labeling, or laminating. This means that we devote 100% of our energy and resources to the research, development, production, and quality control of the aluminum foil substrate, ensuring that every roll of aluminum foil delivered to our packaging customers possesses superior and stable basic performance.

Professional Alloy Formulas

We deeply understand the subtle packaging requirements of different chocolate products. Therefore, we offer a variety of proven, high-quality aluminum alloys to meet diverse applications:

- 1235 Alloy: High-purity aluminum with a soft texture, excellent formability, and a high gloss. It is ideal for packaging standard chocolate bars, gold coins, and other products, giving them a dazzling golden appearance.

- 8079 Alloy: Specifically designed for high-performance barrier packaging. By adding appropriate amounts of iron and silicon, it significantly improves strength and toughness, while offering industry-leading pinhole control and barrier properties. This material is the preferred choice for high-end chocolates and filled chocolates that are moisture-sensitive or require an extended shelf life, providing reliable golden protection.

- 8011 & 3003 Alloys: Offer balanced performance and a good price-performance ratio, suitable for a wide range of chocolate packaging needs, while also producing a premium golden color.

Precision Process Control

- Thickness Tolerance: Strictly controlled within ±5%, ensuring packaging consistency and compatibility with high-speed packaging machines.

- Surface Treatment: Advanced rolling and surface cleaning technologies ensure a clean, oil-free surface, a uniform and bright gloss, and an attractive, professional golden color.

- Slitting Precision: Widths range from 100mm to 1600mm, meeting the needs of various packaging machines, with clean, burr-free edges.

- Global Standard Certification: Our production strictly adheres to international and national standards such as ASTM-B209, EN 573-1, and GB/T 3880.1-2006, ensuring global market access and reliable food safety.

Scaled Supply and Flexible Service

- Production Capacity Guarantee: Our own factory ensures stable supply.

- Flexible Customization: Thickness (0.006mm – 0.2mm), width, finish (O, H18, H19, etc. to meet your softness and hardness requirements), and alloy can be customized upon request.

- Efficient Logistics: Standard roll diameters range from 300mm to 800mm, and customization is possible. The minimum order quantity is 3 tons, and delivery is 7-25 days after order confirmation. We support various trade terms such as FOB, CIF, CFR, and CNF.

- Sample Support: Free samples are provided for your testing and verification.

Summarize

Yongsheng Aluminum’s chocolate packaging aluminum foil is more than just a packaging material; it is an extension of our commitment to quality for your chocolate products. Its scientifically proven, ultimate barrier properties provide a solid barrier for your chocolate against light, oxygen, moisture, and flavors, preserving its freshness, aroma, and perfect form. Choosing YSA means choosing.

- Reliable Quality: Specializing in aluminum foil substrates, ensuring stable and superior performance.

- Professional Support: Extensive alloy and process expertise, providing expert solutions.

- Efficient Supply: Scaled production, flexible response, and on-time delivery.

- Global Trust: Complying with international standards, serving customers worldwide.