Mirror aluminum, also known as reflective aluminum or polished aluminum, is a versatile material that finds application across various industries due to its excellent reflective properties, lightweight nature, and durability. This article delves into the different types of mirror aluminum and their diverse applications.

Types of Mirror Aluminum

1. Anodized Mirror Aluminum: This type involves an electrochemical process that enhances the aluminum’s natural oxide layer, making it more durable and resistant to corrosion. Anodized mirror aluminum typically has a high reflectivity and is used in applications where both aesthetics and functionality are critical.

2. Polished Mirror Aluminum: Polishing involves mechanically buffing the aluminum surface to achieve a high level of reflectivity. This type is often used in decorative applications due to its brilliant finish.

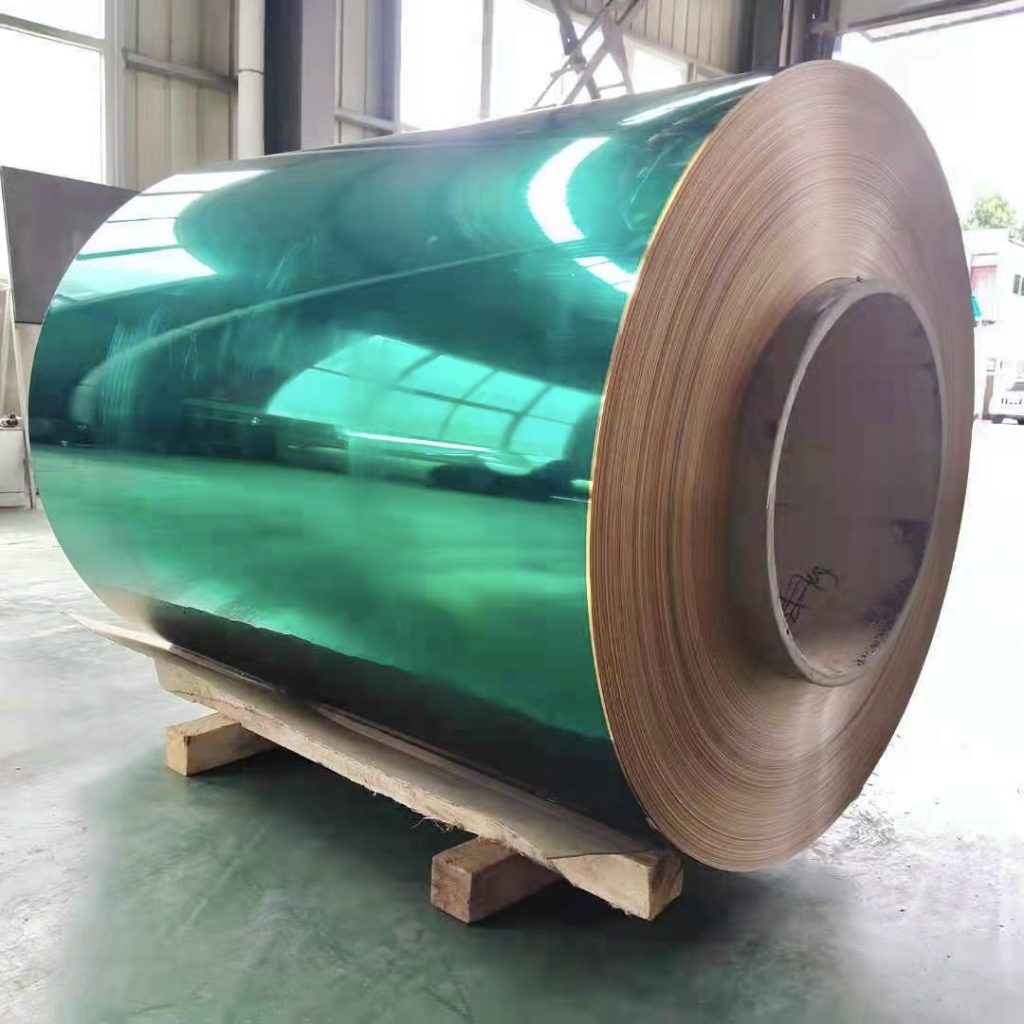

3. Coated Mirror Aluminum: This type includes a protective coating, which can be clear or colored, that enhances the reflective properties and protects the surface from scratches and environmental damage. Coated mirror aluminum is used where additional durability is required.

4. Laminate Mirror Aluminum: A laminate layer is applied to the aluminum surface to achieve a mirror finish. This type is common in applications where high reflectivity is needed without extensive surface treatment.

Applications of Mirror Aluminum

1. Architecture and Interior Design: Mirror aluminum is extensively used in building facades, ceilings, and decorative panels. Its reflective properties can enhance natural light, contributing to energy efficiency and creating visually appealing designs.

2. Automotive Industry: In the automotive sector, mirror aluminum is used for trim, decorative elements, and reflective components. It provides a sleek, modern look while being lightweight, which contributes to the overall fuel efficiency of vehicles.

3. Lighting: One of the most significant applications of mirror aluminum is in the lighting industry. It is used in reflectors and light fixtures to maximize the efficiency of light sources by reflecting and directing light precisely where needed.

4. Solar Energy: Mirror aluminum is used in solar panels and solar collectors. Its high reflectivity enhances the concentration of sunlight, improving the efficiency of solar energy systems.

5. Electronics: In electronics, mirror aluminum is used for casing and reflectors in devices like LCD screens, LED lighting, and other electronic equipment. Its reflective properties and lightweight nature make it an ideal material for these applications.

6. Aerospace: The aerospace industry uses mirror aluminum for various components due to its strength-to-weight ratio and reflective properties, which are essential for both structural elements and thermal management.

7. Consumer Goods: Mirror aluminum is used in household appliances, furniture, and other consumer goods. Its aesthetic appeal and durability make it a popular choice for items that require a modern, sleek look.

8. Signage and Display: The advertising and signage industry uses mirror aluminum for high-impact displays and signs. Its ability to catch and reflect light makes signs more noticeable and attractive.

Conclusion

Mirror aluminum, with its various types and extensive applications, is a crucial material in multiple industries. Whether it’s enhancing the aesthetics of a building, improving the efficiency of solar panels, or providing a modern look in automotive design, mirror aluminum’s versatility and reflective properties make it invaluable. Understanding the different types of mirror aluminum and their specific uses can help industries choose the right material for their needs, ensuring both functionality and aesthetic appeal.