The 1/8 aluminum sheet is a versatile material used in various industries and applications. With its specific thickness of 1/8 inch (0.125 inches or 3.175 mm), it offers a balance of strength and weight, making it suitable for a wide range of projects. Understanding its characteristics and applications is crucial for utilizing its potential effectively.

Section 1: Characteristics of 1/8 Aluminum Sheet

Thickness and Size

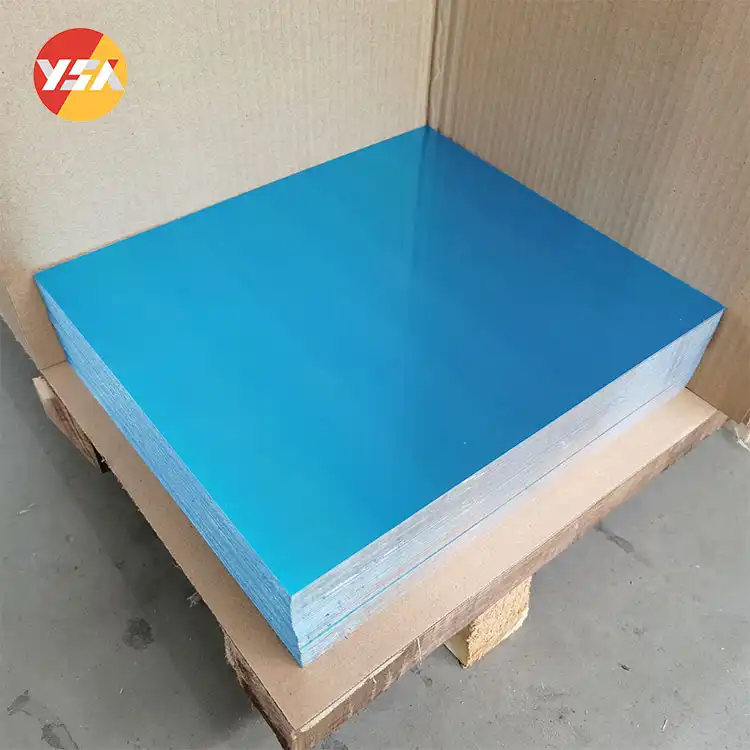

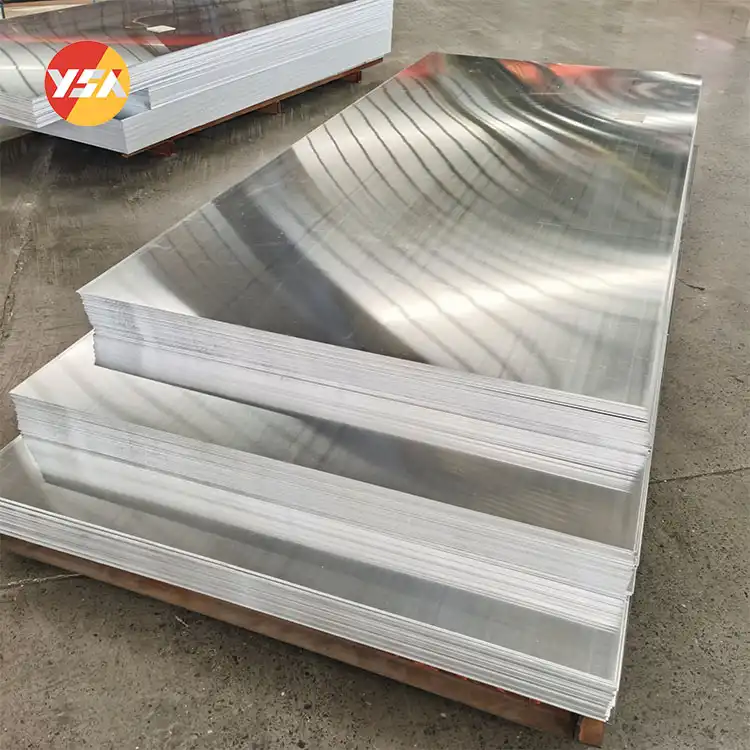

The 1/8 aluminum sheet refers to a sheet with a thickness of 1/8 inch or approximately 0.125 inches (3.175 mm). Compared to other aluminum sheet thicknesses, such as 1/16 inch or 1/4 inch, it occupies a middle ground in terms of thickness. Common sizes available in the market include standard sheet sizes of 4′ x 8′ aluminum sheet or smaller cut-to-size options.

Aluminum Alloys

1/8 aluminum sheets are manufactured using various aluminum alloys. Different alloys offer different characteristics such as strength, corrosion resistance, and weldability. Popular alloy choices for 1/8 inch thickness include 5052, 6061 and 3003 aluminum alloy due to their favorable properties in terms of strength and workability.

Strength and Weight

One of the notable advantages of 1/8 aluminum sheet is its strength-to-weight ratio. It provides sufficient strength while being relatively lightweight compared to other materials. This characteristic makes it desirable for applications where weight reduction is crucial without compromising structural integrity.

Formability and Fabrication

1/8 aluminum sheet is highly formable and can be easily fabricated into desired shapes and sizes. Common forming methods include bending, shaping, and rolling. It also exhibits good weldability, allowing for various welding and joining techniques to be employed during fabrication processes.

| Property | Value |

| Thickness | 1/8 inch |

| Size | Varies (customizable) |

| Strength | Moderate |

| Weight | Light |

| Hardness | Varies (alloy-dependent) |

| Aluminum Alloys | 1100, 3003, 5052, 6061, 7075, etc. |

Section 2: Applications of 1/8 Aluminum Sheet

1/8 aluminum sheet has a wide range of applications in different industries, including automotive, marine and other fields. The following are specific applications of 1/8 aluminum sheet in automotive and marine:

Automotive Industry

- Body panels: 1/8 aluminum sheet is widely used in the manufacture of body panels for automobiles, such as doors, roofs, and rear ends. Its lightweight properties help improve fuel efficiency and reduce overall vehicle weight.

- Interior components: 1/8 aluminum sheet is also used for the interior components of automobiles, such as instrument panels, door trims, center consoles, and so on. It not only provides an elegant appearance, but also has good durability and corrosion resistance.

- Radiator Hood: 1/8 aluminum sheet can be used to manufacture automotive radiator hoods, which help the radiator cool down effectively and protect the engine from overheating.

Marine Industry

- Hull Structures: In the construction of ships, 1/8 aluminum sheet is frequently utilized to create hull structures like hulls and bulkheads. Its lightweight characteristics aid enhance ship handling and fuel efficiency, while its corrosion resistance enables it to be used for extended periods of time in marine conditions.

- Ship fittings and equipment: Additionally, fittings and equipment for ships, such as ship decks, cargo crates, fenders, etc., are made from 1/8 aluminum sheet. It is strong and long-lasting. It is strong and long-lasting enough to survive the difficulties of the maritime process and the impacts of the outside environment.

Aside from the automotive and maritime sectors, other industries that rely heavily on 1/8 aluminum sheet include:

The construction sector

- Roofs and outside siding: They can be made out of 1/8 aluminum sheet, which has the corrosion resistance and toughness to endure the effects of weather extremes and the environment.

- Building support and decoration: Beams, columns, door and window frames, and decorative panels are all examples of how 1/8 aluminum panels are used to support and decorate buildings.

Manufacturing and Industrial Applications

- Mechanical parts and accessories: 1/8 aluminum sheet is widely used to manufacture parts and accessories for mechanical equipment, such as machine housings, brackets, fixtures and so on.

- Containers and Hoods: 1/8 aluminum sheet can be used to manufacture various containers and hoods, such as electronic equipment shells, instrument boxes, chassis and so on.

Section 3: Yongsheng 1/8 Aluminum Sheet Introduction

Yongsheng 1/8 aluminum sheet shows several advantages that make it a popular choice in various applications. Firstly, its thickness of 1/8 inch strikes a balance between durability and versatility. It is substantial enough to provide structural integrity and resistance to bending or warping, while still being manageable and easy to work with. Secondly, its lightweight nature offers benefits such as ease of transportation, reduced installation effort, and improved fuel efficiency in industries like aerospace and automotive. Additionally, the 1/8 aluminum sheet exhibits inherent corrosion resistance, making it suitable for outdoor and marine environments. Its malleability allows for shaping and forming into complex designs, offering design flexibility and customization. Furthermore, aluminum’s excellent conductivity makes it suitable for heat transfer applications. Lastly, a wide range of aluminum alloys, such as 1100, 3003, 5052, 6061, and 7075, are available in the 1/8 thickness, providing different strength, hardness, and other properties to meet specific requirements across industries.

Summary

The 1/8 aluminum sheet offers a unique combination of strength, lightweight, formability, and corrosion resistance. Its versatility allows it to be used in various industries and applications, including construction, automotive, aerospace, manufacturing, marine, and electrical/electronics. By understanding its characteristics and considering specific application requirements, one can harness the benefits of this remarkable material effectively. As technology advances, further innovations and advancements in aluminum sheet technology are expected, expanding the applications of 1/8 aluminum sheet in the future.

FAQ

What are aluminum perforated sheets?

Aluminum perforated sheets are sheets of aluminum that have been punched with a variety of hole sizes and patterns to provide an aesthetic appeal. They offer savings in weight, passage of light, liquid, sound, and air, while providing a decorative or ornamental effect. They are commonly used in interior and exterior design, security, sifting, machinery guards, enclosures, sign panels, and more. The sheets are corrosive resistant and easy to weld, cut, and form with proper equipment. The mechanical properties of perforated aluminum sheets are non-magnetic with tensile strength of 22K+/- and yield strength of 21K+/-. The available stock sizes include 1ft x 4ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft or cut to size.

What are foam sheets made of?

Foam sheets are made of different materials depending on their intended use. Commercial foam sheets are generally made of synthetic rubber, natural latex or polyurethane. Latex foam rubber is well known for its endurance and is used in mattresses. Polyurethane is a thermosetting polymer that comes from a combination of Methyl di-isocyanate and polyethylene and some other chemical additives.

Craft foam sheets, on the other hand, are made of ethylene-vinyl acetate copolymer foam (EVA), a durable plastic foam that is an alternative to materials such as rubber and vinyl. EVA foam sheets are popular for adding texture to a crafted item because of their ability to remain strong at low temperatures and their resistance to UV rays and cracking.