Aluminum alloys come in a wide variety and offer versatility. And 6061 aluminum and 3003 alloy aluminum are one of the popular alloys of 6000 series aluminum sheet and 3000 series aluminum plate respectively. Both are lightweight, durable and recyclable, making them popular choices for everything from construction to aerospace. This article compares these two common alloys specifically to help you choose the most suitable material for your project.

6061 Aluminum Review

6061 aluminum sheet is a high-quality alloy product produced by heat treatment and pre-stretching. The main components are aluminum, magnesium and silicon. It has been standardized by the Aluminum Association of America (AA) and is available in various forms such as polished, coated, anodized, mirrored, embossed, etc. Its performance and characteristics: high tensile strength, good formability and weldability make it widely used. Used in various applications. No matter in entertainment, building structure, marine ship, or aerospace field, 6061 aluminum plate can be seen. Compared with other aluminum alloys in the 6000 series, such as 6005 aluminum and 6063 aluminum, 6061 has higher strength than them and is more suitable for applications with high formability.

3003 Aluminum Review

3003 aluminum sheet is part of the 3xxx series of aluminum alloys consisting primarily of aluminum and manganese as the primary alloying elements. This alloy is widely used in various industries. Its properties include excellent formability, moderate strength and good corrosion resistance. Although 3003 is not as strong as the similar series of 3004, 3005, and 3105 aluminum sheets, 3003 is highly regarded for its economy and ease of welding and brazing, making it the first choice of manufacturers. Widely used in cooking utensils, chemical equipment, storage tanks, roofs and heat exchangers, etc.

Chemical Composition Comparison

| Alloy | 6061 aluminium | 3003 alloy aluminium |

| Chemical Composition | Aluminum(Al): 97.9%, Magnesium (Mg): 1.0-1.2%, Silicon (Si): 0.4-0.8%,Iron (Fe): 0.7%,Copper(Cu): 0.15-0.4%, Zinc(Zn): 0.25%,Titanium(Ti): 0.15%, Manganese(Mn): 0.15% (maximum),Chromium(Cr): 0.04-0.35%,Other Elements: 0.05% each,0.15% total,Remainder: Aluminum | Aluminum(Al): 98.6%, Manganese (Mn): 1.0-1.5%, Other Elements: 0.20% (maximum),Remainder: Aluminum |

| Specific Gravity | 2.70 g/cm³ | 2.73 g/cm³ |

Features Comparison

Choosing between 3003 and 6061 aluminum profiles can be difficult due to their interchangeable nature. However, there are some distinguishing characteristics that help to differentiate between the two.

Strength and Toughness:

In terms of absolute strength, 6061 alloy is the better choice. Due to the presence of silicon and magnesium in its alloy composition, 6061 aluminum alloy has higher strength. 276 has a higher yield strength of 3003 MPa (185 has a yield strength of 6061 MPa), making it a better choice for heavy-duty applications such as machining structural parts.

In addition, 6061 aluminum is stronger than 3003 alloy when used in joints. Its higher yield also plays a role here. It is a better choice for applications such as scaffolding because it can withstand heavier loads even when connected by screws.

Machinability:

When it comes to machinability, 6061 aluminum alloy also ranks high. Although it is a harder material, its accompanying properties, such as resistance to surface damage (e.g. scratching), make it a better machining option. However, its hardness also means it’s a poorer finishing option. Therefore, if you need parts that need to be aesthetically pleasing after machining, 3003 alloy may be a better choice. If you want to use an anodized finish, you may want to stay away from 3003 alloy because of its association with the anodizing process.

Corrosion Resistance:

Both metals have similar levels of corrosion resistance. Since they both contain copper, they are both slightly more susceptible to corrosion, especially when in contact with alkaline surfaces. However, if such conditions do not exist, both metals protect the alloy by preventing corrosion through the formation of a non-reactive oxide layer on the surface of the metal. However, it is also worth noting that the level of protection may also be affected by atmospheric/water conditions.

Stratigraphic Characterization:

Forming refers to the production and processing of finished products from raw materials. The forming characteristics of any metal will involve its tendency to undergo various machining processes, such as extrusion, rolling, forging, and so on. In such processes, the softer the metal, the better, so the machinist can easily manipulate it. For this category, alloy 3003 is the better choice. Due to its lower yield strength and shear strength, it is more suitable for molding applications than 6061 alloy.

Price:

In terms of price, 3003 alloy is usually one of the less expensive ones. However, you should know that the price may vary depending on the alloy variant and the supplier you buy from.

Properties Comparison

Mechanical Properties

| Alloy | 6061 aluminum | 3003 aluminum |

| Tensile Strength (MPa) | 276-310 | 130-180 |

| Yield Strength (MPa) | 241-276 | 55-145 |

| Elongation (%) | 8-14 | 20-30 |

Physical Properties

| Alloy | 6061 aluminum | 3003 aluminum |

| Density (g/cm³) | 2.70 | 2.73 |

| Melting Point (°C) | 582-652 | 655-685 |

| Thermal Expansion (10^-6/°C) | 23.6 | 23.2 |

| Modulus of Elasticity (GPa) | 68-70 | 69-72 |

| Thermal Conductivity (W/m·K) | 151-202 | 125-160 |

| Electrical Resistivity (nΩ·m) | 3.95 | 4.25 |

Applications Comparison

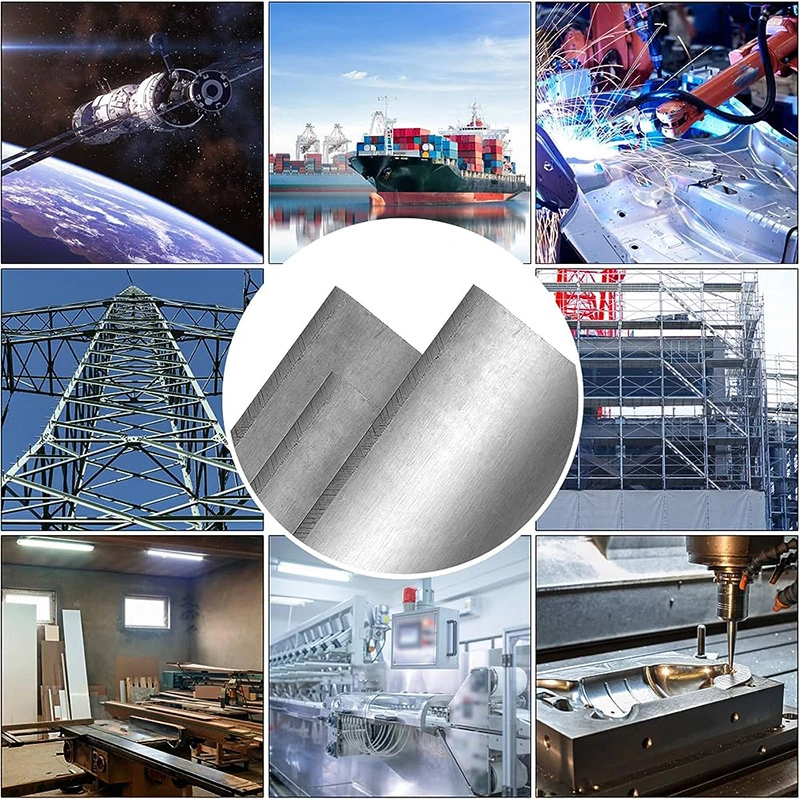

6061 aluminum is a versatile alloy with applications in various industries. For example: in the aerospace industry, 6061 aluminum is used to make aircraft components, such as wings, fuselage sections and structural parts; in the marine industry, 6061 aluminum is used to make parts, hulls and other components that require corrosion resistance and durable parts; compared with the commonly used 5052 aluminum plates commonly used in automobiles, the automotive industry uses 6061 aluminum to manufacture auto parts, including engine parts, gearbox parts, etc., while 5052 focuses on the manufacture of auto panels, fuel tanks and heat exchangers; in addition, 6061 aluminum is also widely used in the production of radiators, electrical connectors, bicycle frames, sports equipment and furniture.

3003 aluminum is typically used in applications requiring a balance of formability, corrosion resistance, and cost-effectiveness. A prominent application is the production of heat exchangers, whose excellent thermal conductivity and corrosion resistance make them suitable for transferring heat in a variety of systems, including air conditioning, refrigeration, and automotive cooling systems; the food and beverage industry uses 3003 aluminum for cookware , food packaging and cooking utensils, because it is non-toxic, easy to form and resistant to food acid and moisture corrosion; due to its resistance to many chemicals, it is also widely used in chemical equipment and storage tanks; in the construction industry, 3003 aluminum used for roofing, especially in residential and commercial construction, it is a favorite in the construction sector along with 1000 series aluminum sheets (such as commonly used grades 1050 aluminum sheet/1060 aluminum sheet/1100 aluminum sheet).

Yongsheng 6061 vs 3003 Aluminum

| Alloy | 6061 aluminum | 3003 aluminum |

| Applications | Mobile phone card slot, mobile phone case, mold, automobile, mask machine, precision machining, etc. | Stock silos, antenna pot materials, power battery shells, automotive heat shields, etc. |

Which Is Better 6061 Or 3003 Aluminum?

The choice of 6061 or 3003 aluminum depends on the specific application and requirements. Both alloys have their own unique properties and advantages.

Aluminum 6061 is a versatile alloy for applications requiring high structural integrity and has good corrosion resistance, especially when compared to other aluminum alloys; this alloy is easy to weld, machine and form, which adds to its versatility. However, due to its desirable properties, 6061 aluminum can be more expensive than some other alloys. 3003 aluminum, on the other hand, is a non-heat treatable alloy that is typically used for general purpose applications such as cooking utensils, roofing, and signage. This alloy also has good weldability and machinability, allowing for efficient manufacturing processes. Compared to some stronger alloys, 3003 aluminum tends to be less expensive.

In short, if you need higher strength and greater structural integrity, 6061 aluminum may be a better choice. On the other hand, if formability, cost-effectiveness, and corrosion resistance are more important to your application, 3003 alloy aluminum may be an appropriate choice.

FAQ:

What is the difference between 3003 0 and 6061 0?

The difference between 3003-O and 6061-O aluminum alloys lies in their composition and properties. 3003 O aluminum contains a small amount of manganese, while aluminum 6061 O contains magnesium, silicon and other alloying elements. This also determines that 6061 alloy aluminum is stronger than 3003 and more expensive than 3003. 3003 alloy aluminum is more suitable for deep drawing or areas with high formability.

Is 6061 aluminum stronger than titanium?

6061 aluminum is no stronger than titanium. Titanium is known for its excellent strength-to-weight ratio, being significantly stronger than aluminum alloys. Compared to aluminum, titanium has higher tensile strength and higher yield strength.

What TIG rod is used for 3003 aluminum?

For TIG welding of 3003 aluminum, the commonly used filler rod is ER4043. ER4043 is a general-purpose aluminum filler alloy that is compatible with a variety of aluminum alloys, including 3003. It is known for its good flowability, excellent corrosion resistance and post-weld strength. ER4043 filler rods produce well-matched color welds and are commonly used in welding applications such as automotive parts, bicycles, aircraft components and other aluminum structures.

Summary

This article mainly compares the chemical composition, physical properties, mechanical properties and applications of 6061 aluminum plate and 3003 aluminum plate, and draws a conclusion: both have their own advantages, and there is no better statement. The key lies in which performance of aluminum plate users value. If you still want to know more about Yongsheng products, please check our official website or directly send an email or call a contact number. We will reply you as soon as possible after receiving the information.