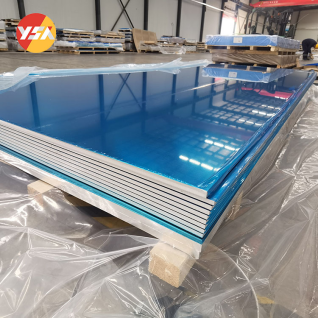

5052 H32 aluminum sheets are widely recognized for their excellent corrosion resistance, formability, and strength. This specific alloy and temper designation makes it particularly suitable for various applications across multiple industries. In this article, we’ll explore the properties, uses, advantages, and considerations related to the 5052 H32 aluminum sheet.

What is 5052 Aluminum Alloy?

The 5052 aluminum alloy is part of the 5000 series, which is known for its high magnesium content. This alloy is particularly favored for marine and automotive applications due to its resistance to seawater corrosion and good weldability. The “H32” temper indicates that the sheet has been strain-hardened and partially annealed, resulting in a moderately high strength level along with excellent workability.

Properties of 5052 H32 Aluminum Sheet

1. Corrosion Resistance: One of the standout features of the 5052 alloy is its exceptional resistance to corrosion. It is especially effective in marine environments, making it ideal for boats and other aquatic applications.

2. Strength: The H32 temper provides a good balance of strength and workability. The yield strength of 5052 H32 aluminum is higher than many other aluminum alloys, making it suitable for applications requiring durability.

3. Formability: This alloy can be easily formed and shaped, allowing for diverse applications. It can be cold worked to create various shapes, making it ideal for parts that need to undergo complex bending or forming.

4. Weldability: 5052 H32 aluminum has excellent weldability, which is essential for many manufacturing processes. It can be welded using various techniques, including MIG and TIG welding.

5. Surface Finish: Aluminum sheets can be treated with different finishes, such as anodizing or painting, improving aesthetics and surface durability.

Common Uses of 5052 H32 Aluminum Sheet

1. Marine Applications: Due to its corrosion resistance, 5052 H32 aluminum is widely used in marine environments for boat hulls, watercraft components, and other marine structures.

2. Automotive Parts: The automotive industry uses 5052 aluminum sheets for fuel tanks, body panels, and structural components, benefiting from its lightweight properties and strength.

3. Architectural Applications: This aluminum alloy is often employed in architectural applications, such as decorative panels, facades, and roofing systems, where both aesthetics and durability are important.

4. Pressure Vessels: 5052 H32 aluminum is suitable for manufacturing pressure vessels and containers, where its strength and pressure resistance are crucial.

5. Sheet Metal Work: Its excellent formability makes it a popular choice in sheet metal applications, including HVAC ducts, enclosures, and cabinets.

Advantages of Using 5052 H32 Aluminum Sheet

– Lightweight: Like most aluminum alloys, 5052 H32 is lightweight, making it an ideal choice for applications where weight reduction is essential.

– Cost-Effective: While aluminum can be more expensive than some other materials, the long lifespan and low maintenance of 5052 H32 contribute to its overall cost-effectiveness.

– Sustainability: Aluminum is highly recyclable, and using 5052 H32 sheets aligns with sustainable practices in manufacturing and construction.

– Versatility: The combination of strength, formability, and corrosion resistance makes 5052 H32 a versatile material suitable for diverse applications.

Tips for Working with 5052 H32 Aluminum Sheet

1. Thickness Selection: Choose the thickness based on your specific application requirements. Thicker sheets provide more strength but may require more effort to manipulate.

2. Fabrication Techniques: Familiarize yourself with suitable fabrication methods. While 5052 H32 is easy to work with, using the right tools and techniques is essential for achieving the best results.

3. Finishing Options: Consider different finishing techniques, such as anodizing or powder coating, to enhance corrosion resistance and appearance.

4. Source Quality Materials: Always source your aluminum sheets from reputable suppliers to ensure quality and compliance with industry standards.

Conclusion

In conclusion, the 5052 H32 aluminum sheet is a remarkable material that combines strength, corrosion resistance, and formability, making it ideal for a wide range of applications. Its versatility shines in industries such as marine, automotive, and construction, where durable and lightweight materials are essential. By understanding its properties and potential uses, you can leverage the advantages of 5052 H32 aluminum sheets for your specific projects and needs.