What Is 6063 Aluminum?

6063 aluminium sheet is an aluminum-magnesium-silicon alloy with magnesium and silicon as the main alloying elements. Is a lightweight, durable and excellent thermal and electrical conductivity material. 6063 aluminum can be easily formed without cracking or breaking, and is widely used in architectural applications, including window frames, door frames and curtain walls; radiators, electrical conduits and auto parts, etc. The material is readily available and inexpensive, and is an irreplaceable aluminum alloy raw material in modern manufacturing and industrial processes.

Usages Of 6063 Aluminum Sheet:

Construction Application:

In the field of construction, 6063 aluminum sheet can be used for various structural components, architectural elements and decorative functions. Due to the alloy’s extrudability, window and door frames as well as curtain wall systems can be made. Due to the alloy’s small weight, total weight and building loads are reduced. Railings and handrails are frequently made from 6063 aluminum sheet because it can be molded into a variety of sizes and shapes. The anodizing or powder coating processes can be used to finish 6063 aluminum sheet, providing a variety of color options and surface treatments. As a result, the building surface can produce both a pleasing aesthetic impression and a decorative effect.

Industrial Application:

6063 aluminum sheet is a popular choice for industrial applications due to its excellent performance and versatility. It belongs to the 6xxx series of aluminum alloys known for their good formability, high corrosion resistance and moderate strength. 6063 aluminum sheet is also used in the transportation industry. It is used to make car floors, truck wheels, and more. Another prominent use is as a heat sink and electrical enclosure. Aluminum’s high thermal conductivity enables efficient heat dissipation, making it suitable for use in electronic equipment and cooling systems. This feature ensures consistent performance and extends the life of sensitive equipment.

Consumer Goods Applications:

6063 aluminum sheet is commonly used in the production of consumer goods such as furniture, mobile phone casings, and precision molds. In the furniture industry, 6063 aluminum sheet can be easily machined and formed, and is often used to make frames for chairs, tables, and other furniture. In addition, the light weight and corrosion resistance of this aluminum sheet is also used to make mobile phone casings, which meet the aesthetic and functional requirements of modern smartphones. 6063 aluminum sheet is often used in the production of precision molds because of its heat resistance and dimensional stability. The alloy’s ability to be easily machined and polished to high precision also makes it ideal for manufacturing molds that require tight tolerances and complex geometries.

Advantages Of 6063 Aluminum Sheet:

The features of 6063 aluminum sheet make it a popular material in a variety of industries. It is ideal for various applications due to its lightweight characteristics, strong corrosion resistance, great formability, and high thermal and electrical conductivity. Because of their corrosion resistance and durability, 6063 aluminum sheets are commonly used in the building industry to produce window frames, door frames, and curtain walls. Because of its small weight and corrosion resistance, it is utilized in the automotive sector to manufacture body panels, wheels, and engine components. Furthermore, because of its eco-friendliness and low maintenance requirements, it is a long-lasting and cost-effective material. Aluminum recycling uses only 5% of the energy needed to make new aluminum, making it a very sustainable resource.

Properties of 6063 Aluminum Sheet:

Bendability Of 6063 Aluminum Sheet:

6063 aluminum sheet is bendable and is a heat-treated bendable aluminum alloy with good plasticity and processability. It can be bent into various shapes through appropriate processes and equipment, such as curved pipes, curved components, etc. The reason why 6063 aluminum can be bent is mainly because of its alloy composition. The addition of silicon element can not only enhance the strength and hardness of the aluminum alloy, but also maintain high plasticity. The degree of bending of the 6063 aluminum plate sheet is mainly determined by the thickness, size, bending radius and bending process of the aluminum plate. If you need to bend 6063 aluminum, be sure to select and control process parameters based on the actual situation to avoid cracks or deformation.

Weldability Of 6063 Aluminum Sheet:

6063 aluminum sheet plate has good welding performance due to the characteristics of its aluminum alloy composition and grain structure. The addition of silicon is beneficial to the melting and fluidity during welding, and the grain refinement and uniformization of 6063 also helps to improve welding quality and reliability. 6063 aluminum can accept a variety of welding methods, common ones include TIG welding, MIG or GMAW welding, MIG-Pulse welding, etc. Pay attention to cleaning the surface before welding, controlling the welding parameters, and using appropriate welding filler materials (usually aluminum alloy welding wire similar to the base material).

What Is 6063 Aluminum Scrap?

Scrap or waste items containing 6063 aluminum alloy are known as 6063 aluminum scrap. These scrap materials are usually by-products of the manufacturing process, processing scrap, end-of-life items, or dismantled garbage.The main sources of 6063 aluminum scrap include production by-products, processing scrap, and rejects.

Methods for processing 6063 aluminum scrap:

- Methods for reusing and recycling 6063 aluminum scrap: Recyclable 6063 aluminum scrap can be recycled and reused. Scrap aluminum can be turned into new 6063 aluminum goods by recycling it and processing it properly. This conserves resources, reduces energy usage, and decreases the demand for raw materials.

- Smelting and extraction: Scrap 6063 aluminum that cannot be reused directly can be smelted and extracted. Aluminum and other important alloying elements can be extracted from scrap by smelting it for future use and applications.

- Environmentally friendly treatment: Environmentally friendly treatment procedures should be utilized for 6063 aluminum scrap that cannot be reused or is difficult to recycle. This may include safe waste disposal, incineration, landfill or other appropriate waste disposal methods to ensure minimal impact on the environment.

Why Is Aluminum 6063 So Popular?

Aluminum 6063 T5:

Aluminum 6063 T5 has a high strength and toughness. The heat-treated T5 aluminum plate is appropriate for applications needing increased load and strength and may meet the needs of numerous applications. 6063 T5 aluminum sheets can be utilized in both indoor and outdoor conditions for extended periods of time without corroding. Because 6063 T5 aluminum plate has a lower density than many other materials, it has outstanding lightweight capabilities. It is also easy to process and form, and may be cut, bent, stamped, welded, and surface treated. This allows producers to design and manufacture goods of varied forms and sizes to meet individual needs. Compared with some high-end materials (such as titanium alloy or stainless steel), the price of 6063 T5 aluminum plate is relatively low. The above are the main reasons why aluminum 6063 T5 is so popular.

Aluminum 6063 T6:

Strong thermal conductivity makes aluminum 6063 T6 a potent heat conductor. It has good ornamental attributes and can get a range of surface treatments and coatings. Aluminum 6063 T6 plates have good welding qualities and can be linked using a variety of welding processes. For straightforward connections, welding methods like TIG (tungsten arc welding), MIG (metal inert gas welding), resistance welding, etc. are frequently utilized. Due to its high degree of plasticity, aluminum 6063 t6 can be shaped by extrusion, rolling, and other processing methods into complex structures and shapes. A sizable supply chain and well-established standards have made aluminum alloy 6063 t6 sheet a frequently used material. This makes it easily available in the market and meets the needs of different industries and applications.

6063 Aluminum Sheet VS Other Aluminum Sheets:

Aluminum 6063 VS Aluminum 6061

Composition and performance are the key distinctions between aluminum 6063 sheet and 6061 aluminum sheet.Magnesium and silicon are also included in 6061 aluminum sheet, which is mostly made of aluminum. It is appropriate for structural and heavy load applications and has more strength and hardness than 6063 aluminum. Anodizing improves 6061’s high corrosion resistance even further. utilized frequently in structural elements, automotive parts, and aircraft and marine parts.Magnesium, silicon, and a trace quantity of copper are also included in the 6063 aluminum sheet plate, which is primarily made of aluminum. It is more suited for extrusion and forming processes because it is more ductile and easier to shape than 6061, which is weaker and harder. Additionally, it has good corrosion resistance, which is strengthened by the anodizing process. It is commonly used in architectural and decorative applications such as window frames, door frames and trim.

Aluminum 6063 VS Aluminum 5052

Both 6063 and 5052 aluminum sheets are popular choices in construction and manufacturing, but they have distinct differences. The main difference is their alloy composition and properties. 6063 aluminum plate belongs to Al-Mg-Si series alloy, which has good formability, medium strength and excellent corrosion resistance. The 5052 aluminum plate belongs to the Al-Mg alloy, with magnesium as the main alloying element. Compared with 6063 aluminum plate, it has higher strength and also exhibits excellent corrosion resistance. In addition, 5052 aluminum sheet has good workability and weldability, making it suitable for marine and transportation applications.

Aluminum 6063 VS Aluminum 5083

6063 aluminum sheet and 5083 aluminum sheet are two different alloys with different properties. 6063 aluminum sheet belongs to the 6xxx series and is mainly used for profiles, such as architectural profiles and window frames, suitable for decorative applications. Compared with 5083 aluminum sheet, 6063 aluminum sheet has lower tensile strength but higher elongation. On the other hand, 5083 aluminum sheet is a member of the 5xxx series, known for its superior strength and marine-grade corrosion resistance. It is commonly used in shipbuilding, offshore structures and other applications where strength and durability are critical. Compared with 6063 aluminum sheet, 5083 has higher tensile strength and better resistance to harsh environments, including seawater. This makes it suitable for structural components subjected to high loads and corrosive conditions.

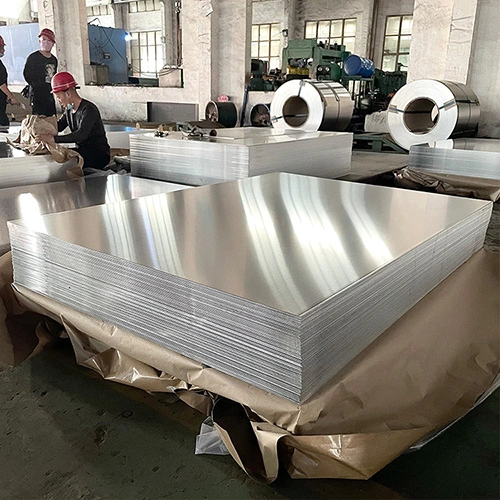

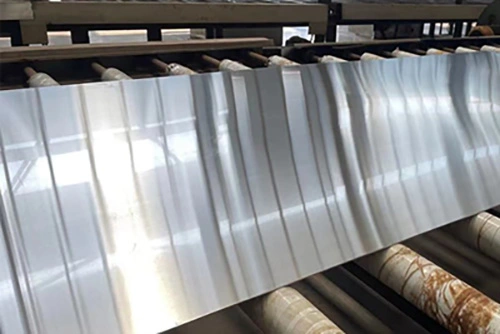

Yongsheng 6063 Aluminum Sheet:

6063 aluminium sheet is one of the advantageous products of Yongsheng Aluminium. The production of alloy 6063 aluminium sheet far exceeds the national standard and provides original warranty. The quality is more guaranteed. Widely used in automotive lightweight, mobile phone shells and other fields, and has a good reputation; The surface of processed aluminum 6063 is very smooth and easy to anodize and colour; It has excellent welding performance and corrosion resistance, and has no tendency to stress corrosion cracking. In heat treatment strengthened aluminium alloy, Al-Mg-Si system alloy is the alloy without stress corrosion cracking; 6063 alloy aluminium sheets strengthened by heat treatment, high impact toughness, insensitive to notch.